AutoJet® Food Safety System Expansion Enables Poultry Processor to Boost Production by 36%

AutoJet® Food Safety System Expansion Enables Poultry Processor to Boost Production by 36%

Problem:

A poultry processor was applying an antimicrobial agent to the whole muscle turkey during the packaging process. The AutoJet Food Safety System in use was effective but demand had exceeded the system's capacity. The processor needed to boost production by 10 turkeys per minute and turned to Spraying Systems Co. for assistance.

Solution:

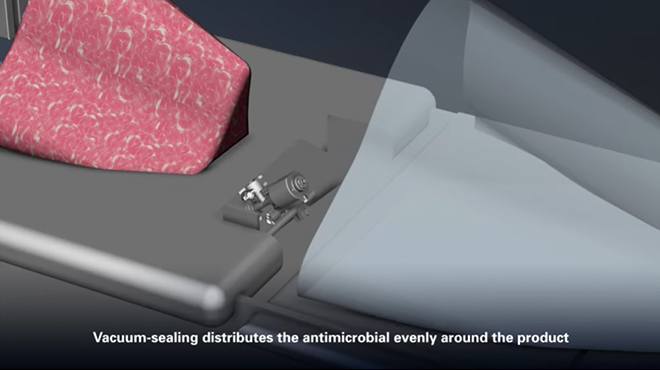

The best solution proved to be an expansion of the existing AutoJet Food Safety system that uses the SLIC (Sprayed Lethality in Container) process. The system doses a precise volume of antimicrobial in the package before the turkey is inserted. Vacuum-sealing of the package distributes the antimicrobial evenly around the product – a process that has been proven effective by the USDA/ARS. Two additional two-channel systems were added to enable four production lines. The systems include a photo-eye sensor on each line to detect the arrival of the product at the packaging station. The sensor sends a signal to the controller to trigger the PulsaJet® nozzle to spray the pre-determined volume of antimicrobial into the package before the turkey is inserted.

Results:

The poultry processor has reached its production goals with the addition of two AutoJet Food Safety Systems and revenue has increased US$9.6 million annually. In addition, the expanded use of the SLIC (Sprayed Lethality in Container) process and the AutoJet Food Safety Systems with precision dosing has advanced the processor's sustainability initiative to eliminate chemical waste.

For complete details of this case study, click here to see the PDF version.