Automobile Parts Manufacturer Reduces Production Costs by 50% with New Lubrication System

Automobile Parts Manufacturer Reduces Production Costs by 50% with New Lubrication System

Problem:

Van-Rob Stamping, a Canadian automobile parts manufacturer, was experiencing difficulty applying the proper amount of lubricant to the metal sheet before forming parts. Overapplication of the lubricant was wasteful and created an unsafe work environment. In addition, the lubricant was not applied uniformly and the company was faced with costly quality problems.

Solution:

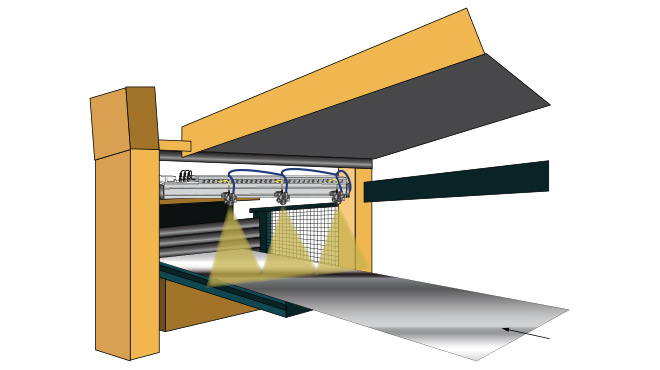

A lubrication header from Spraying Systems Co. equipped with three AA250AUH automatic spray nozzles has solved Van-Rob Stamping’s problems. The electrically-actuated nozzles operate at low pressure, eliminating overspray and lubricant waste. In addition, the nozzles only spray when a signal from the press is received, conserving lubricant.

Results:

The new lubrication header has solved Van-Rob Stamping’s overspray problem. Parts quality has improved, worker safety has increased and lubricant use has been reduced dramatically. Since the system has been installed, lubricant cost has been reduced by more than 50%. The company recouped its equipment investment in less than one month.

For complete details of this case study click here to see the PDF version.