Unmatched Tank Cleaning Solutions for Every Application

At Spraying Systems Co., we offer an extensive range of tank cleaning products under our TankJet® and Cloud-Sellers® brands, ensuring that no matter your tank size or cleaning challenge, we have the optimal solution. Our advanced fluid- and motor-driven technologies deliver high-impact cleaning, effectively removing residues and contaminants while minimizing manual labor, water, and chemical usage. With decades of experience across various industries, our experts are ready to help you select the ideal tank cleaning solution to enhance your operations.

Find Local Expert

A Legacy of Excellence in Tank Cleaning Solutions

Spraying Systems Co. has a long-standing legacy of delivering innovative tank cleaning technologies through our TankJet® and Cloud-Sellers® product lines.

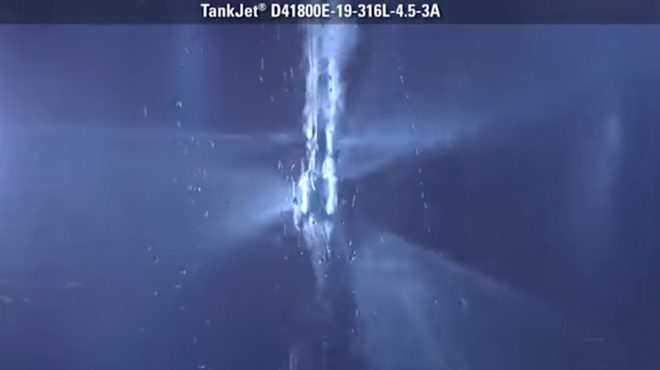

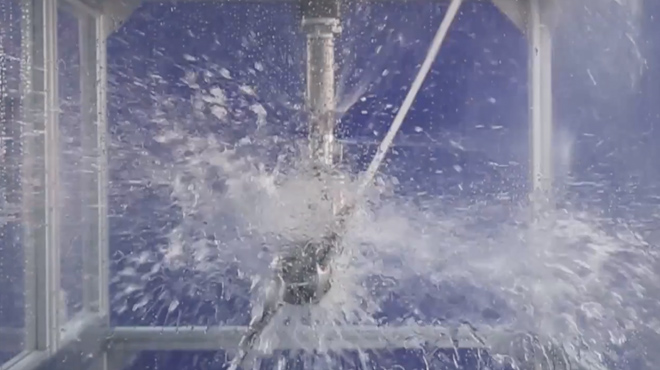

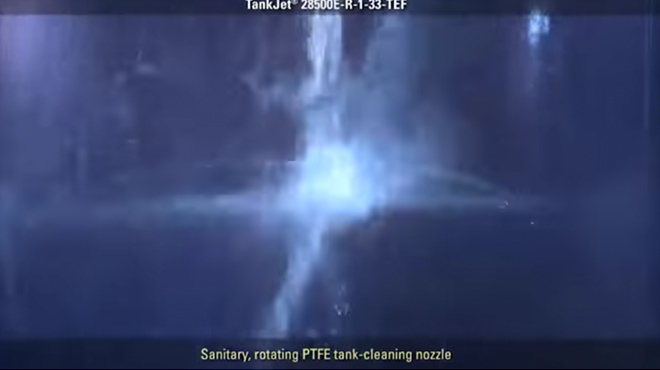

TankJet®

In the early 1980s, Spraying Systems Co. began designing specialized tank cleaning equipment to meet increasing demand for more efficient, reliable solutions. What would later be known as the TankJet® line evolved from simple spray balls to advanced, automated cleaners—serving a wide range of industries and tank sizes. This growth reflects our commitment to continuous innovation and solving the evolving challenges of industrial cleaning.

Cloud-Sellers®

Cloud Company was founded in 1951, specializing in fluid-driven rotating spray devices for internal tank cleaning. In 2008, Cloud acquired the Sellers brand—originally established in 1871—renowned for pioneering tank cleaning technologies including the Giffard Steam Injector, Troll Ball, and Tankmaster. This acquisition expanded Cloud’s capabilities and reinforced its reputation for high-performance tank cleaning equipment.

One of the standout products from this legacy is the Cloud-Sellers 360® Fluid-Driven Tank Cleaner. Designed to tackle tough residues in blending, brewing, distilling, food processing, and winemaking applications, the Model 360 delivers high-impact cleaning in a durable, American-made design. Built for demanding environments, it offers long service life and exceptional performance without compromise.

Combining Experience

In February 2023, Spraying Systems Co. acquired Cloud Company, integrating the Cloud-Sellers product line into our tank cleaning portfolio. This strategic acquisition brought together decades of engineering excellence, expanding our ability to offer customers a more comprehensive selection of tank cleaning solutions.

Today, TankJet and Cloud-Sellers products represent the forefront of tank cleaning innovation—engineered for quality, performance, and reliability in every application.

Maximizing Tank Cleaning Performance

Certified for the Toughest Standards

Our tank cleaners meet the industry’s most rigorous certifications, including 3-A Sanitary Standards and ATEX directives. Designed for food, beverage, dairy, and pharmaceutical applications, these cleaners ensure compliance with the highest hygiene and safety requirements—delivering unmatched cleaning performance where it matters most.

Keep Your Tank Cleaners Running at Peak Performance

Regular maintenance is essential to maximize the lifespan and efficiency of your Cloud-Sellers® 360 and Cloud-Sellers® 180 tank cleaners. Over time, wear on critical components can lead to reduced tank cleaning performance, increased downtime, and costly repairs. Our expert preventative maintenance services help you avoid unexpected failures, reduce operational costs, and keep your production running smoothly. With fast turnaround times from our service centers in Wheaton, IL; San Luis Obispo, CA; and Chester Springs, PA, you get the support you need—when you need it.

Explore Our Industries

Spraying Systems Co. offers industry-leading tank cleaning solutions designed to meet the specific demands of diverse applications. Whether ensuring sanitary compliance in food and beverage processing, maintaining efficiency in chemical production, or optimizing cleaning in pharmaceutical and industrial environments, our advanced equipment delivers superior performance. With a focus on hygiene, efficiency, and cost savings, we provide reliable solutions to keep your operations running smoothly.

Sustainable Practices with Spraying Systems Co.

Spraying Systems Co. is committed to helping industries adopt sustainable practices by optimizing water usage, reducing cleaning waste, and minimizing environmental impact. Schedule a sustainability assessment to discover cost-saving opportunities and improve resource efficiency with our advanced spray technology.

Contact a sustainability expert