Bakery Spray Coating

Bakery Spray Coating

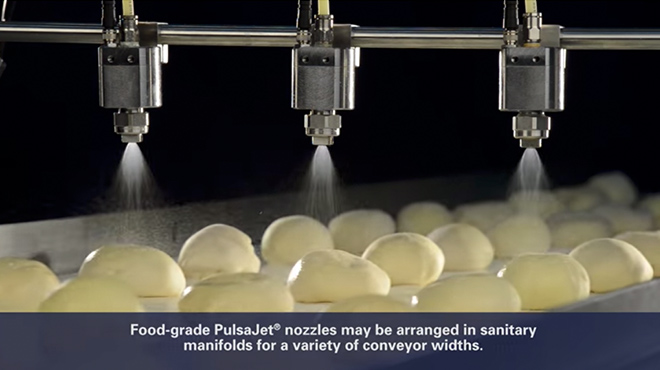

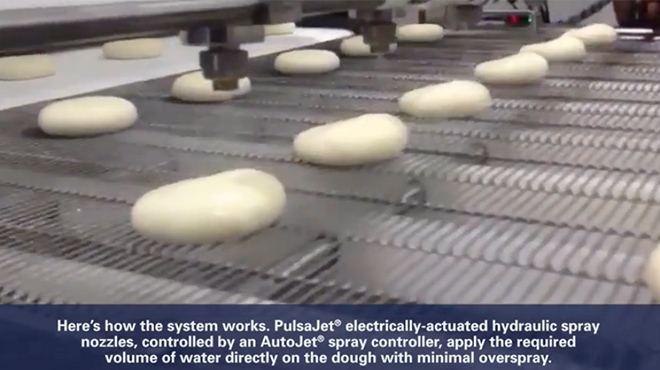

Like other manufacturing sectors, the baking industry continually faces competitive pressures. In their ongoing efforts to improve quality, boost productivity and control costs, commercial bakeries are finding that spray technology can be a very effective tool in meeting a number of persistent challenges.

Is Your Coating Sprayable?

The answer to this question is, almost always, yes. We have a proven track record of using spray technology to apply just about every coating, ingredient, slurry, flavoring and topping. The best way to determine if your coating is sprayable is with a proof-of-concept test in our spray laboratories.

Temperature Controlled Systems

Precise temperature control is essential to the successful application of viscous coatings. That’s why our AccuCoat spray systems are equipped to automatically adjust and maintain the temperature of the coating to ensure consistent, uniform coverage. Most AccuCoat spray systems use heat to ensure even application but systems that provide chilling are also available.

Our heated systems are perfect for butter, chocolate, syrup, & oil applications; while cooling can be used for egg wash applications.