Why Optimize?

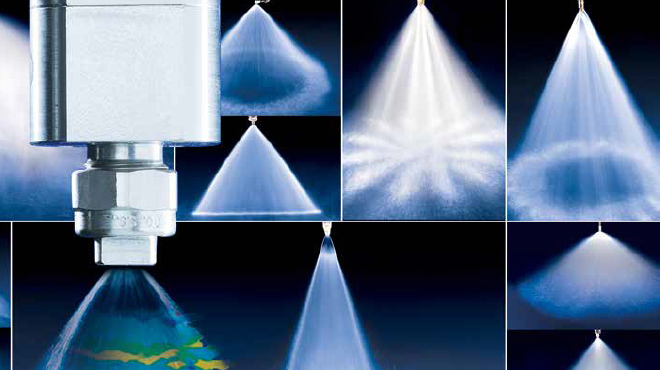

Spray systems are often perceived as pretty simple. As long as a nozzle sprays, it seems to be working properly — but that’s not always the case. Spray nozzles are engineered to perform in a specific way under specific conditions. When nozzles don’t perform as designed, they contribute to significant waste and put quality at risk. To keep operating costs as low as possible, you need a plan for optimizing your spray system.

Spray Optimization Benefits Your Entire Business

Here are some bottom-line results from spray optimization:

- Improved product or process quality

- Trouble-free operation with no unscheduled downtime

- Reduced waste of water, chemicals and energy

- Minimal environmental impact

Optimizing Is Easy

There are lots of ways to optimize your spray operations, such as:

- Improving and / or monitoring your maintenance procedures

- Upgrading to nozzles of a more advanced type or more wear-resistant material

- Adding a spray controller