Plastic Bottle Manufacturer Saves US$92,000 a Year with Automated Spray System

Plastic Bottle Manufacturer Saves US$92,000 a Year with Automated Spray System

A plastic bottle manufacturer was using air atomizing systems to spray a costly lubricant to prevent newly formed bottles from sticking together.

Problem:

A plastic bottle manufacturer was using air atomizing systems to spray a costly lubricant to prevent newly formed bottles from sticking together. The systems operated continuously, spraying lubricant when bottles were not present. The lubricant application wasn’t consistent with some bottles being coated with too much lubricant and others not enough. Another problem was the excessive misting produced by the air atomizing spray nozzles. The work environment was messy and hazardous and maintenance time was substantial.

Solution:

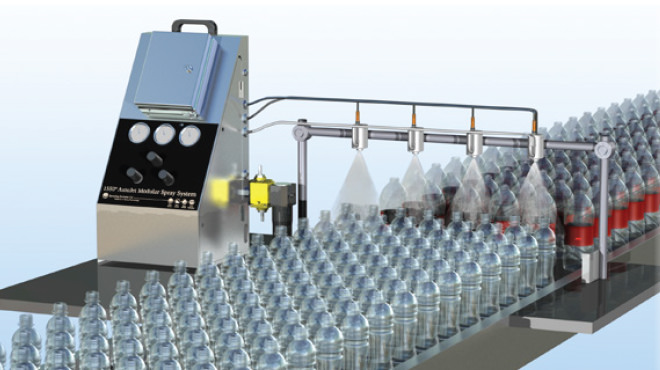

The bottle manufacturer now uses AutoJet® automated spray systems to apply the lubricant. Each system is equipped with PulsaJet® electrically-actuated air atomizing nozzles and is controlled by an AutoJet Model 1550+ Modular Spray System. Using Precision Spray Control (PSC), the proper volume of lubricant is now applied consistently with minimal waste. The spray controller makes automatic adjustments to flow rate based on line speed without adjusting spray pressure to ensure drop size, spray angle and coverage remain consistent. In addition, sensors relay bottle height and presence to the controller. The controller then triggers the nozzles to spray. The reductions in overspray and misting eliminate any production restricting coverage, safety and maintenance issues.

Results:

The AutoJet® automated spray systems with Precision Spray Control (PSC) ensure the proper volume of lubricant is consistently applied to the bottles with minimal waste and misting as they move through the spray stations. As a result, lubricant consumption has been reduced by 70%, production has increased by approximately 20% and maintenance workers have been deployed to other tasks. The combined savings are over US$92,000 a year with a payback period of eight months.

For complete details of this case study click here to see the PDF version.