Fiber-Cement Siding Manufacturer Reduces Coating Consumption, Saves US$80,000 Annually with Automated Spray System

Fiber-Cement Siding Manufacturer Reduces Coating Consumption, Saves US$80,000 Annually with Automated Spray System

Problem:

A global manufacturer of fiber-cement building products needed to spray a proprietary resin coating on siding boards to aid the drying process. The previous spray system, which lacked a controller, resulted in inconsistent coating and messy overspray. The system’s inability to automatically adjust flow rate based on line speed was especially problematic as boards were being produced at speeds that varied up to 65%.

The company required a spray solution that would precisely apply the coating with minimal overspray and waste, thereby reducing maintenance, cleanup, scrap material and associated man-hours. Achieving these objectives while, at the same time, being able to make on-the-fly changes to line speeds and production schedules without switching out spray nozzles also was paramount.

Solution:

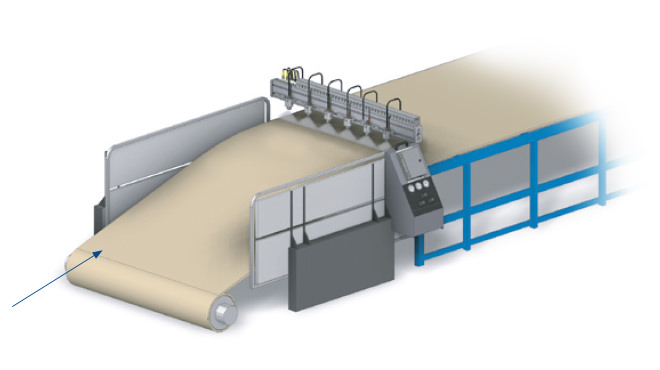

The company purchased Spraying Systems Co.’s AutoJet® Model 1550+ Modular Spray System, which included a 98250 manifold equipped with six PulsaJet® AA10000AUH-104210 electrically actuated spray nozzles and UniJet® PWMD tips. Prior to entering the drying oven, siding boards were conveyed under the 66-inch (1676 mm) spray manifold and sprayed with the resin coating from an 8.5-inch (216 mm) spray height. A flow rate range of 0.375 to 2 gallons/hour (1.4 to 7.6 liters/hour) per nozzle was used.

The AutoJet system provided Precision Spray Control (PSC), which ensured accurate, uniform placement of the resin coating with minimal waste—even with line speeds ranging from 300 to 500 feet/minute (91.4 to 152.4 meters/minute). With the system’s ability to produce a wide range of flow rates, the need to modify the spray settings during production changes was eliminated.

Results:

The AutoJet® Model 1550+ Modular Spray System provided significant cost benefits over the first four months of operation. It reduced consumption of the expensive resin coating and cleanup of messy overspray, while improved quality consistency led to less scrap being created and hauled away. In addition, flow rate concerns were put to rest thanks to the system’s PSC.

The system’s success led the fiber-cement manufacturer to project an annual savings of US$80,000, a payback period of less than three months on the investment. It also resulted in the company approving the capital expenditure for 12 additional AutoJet systems for similar use in other plants.

For complete details of this case study click here to see the PDF version.