Flat Glass Manufacturer Reduces Scrap by 75% with Automated Spray Coating System

Flat Glass Manufacturer Reduces Scrap by 75% with Automated Spray Coating System

Problem:

A glass manufacturer needed to apply a thin coating of zinc citrate on flat glass while it was on the float line. The coating protects the glass from corrosion and discoloration.

The challenges were numerous. Coating across the full width of the glass ribbon needed to be uniform to ensure product quality. Frequent nozzle clogging was causing high scrap rates. Consistent application volume was critical even though variations in glass thickness required different application rates and line speeds varied greatly.

Reducing operating costs was also desirable. The existing system used air atomizing nozzles, wasted zinc citrate solution, required mist extraction equipment and needed extensive daily maintenance.

Solution:

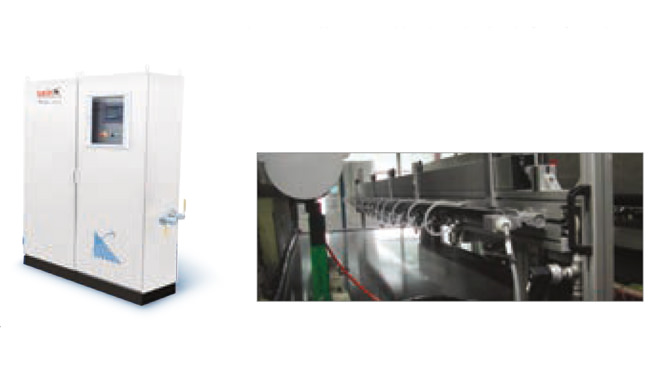

An AutoJet® Spray System with 12 electrically-actuated hydraulic PulsaJet® spray nozzles provides the necessary flexibility and precision. Powered by a Model 2250 AutoJet Spray Controller, the system accurately adjusts the flow of zinc citrate solution with Precision Spray Control (PSC). Spray pressure remains constant with PSC, enabling the optimal spray angle to be maintained despite changes in flow rate. This ensures uniform coverage across the width of the ribbon.

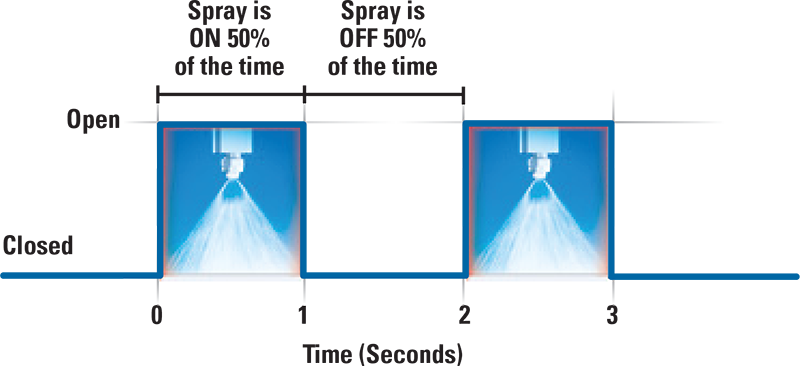

Changing the frequency and duty cycle of each nozzle instantaneously adjusts flow rate for line speed changes and maintains the correct volume of coating. Nozzles can also be activated individually to accommodate different ribbon widths.

In addition to repeatable spray precision, the turnkey AutoJet Spray System is easy to operate and maintain. The system requires no compressed air and has eliminated clogging and misting problems. The nozzles are mounted on a 3800 mm (150”) wide frame which can easily be rolled away from the production line for quick maintenance.

The system mixes the water and zinc citrate solution on demand, eliminating the need to store pre-mixed coating. An optional reverse osmosis unit that produces demineralized and softened water without the use of hydrochloric acid and sodium hydroxide is available.

Results:

The AutoJet® Spray System ensures product quality by providing uniform coating across the full width of the glass ribbon regardless of line speed, ribbon width or thickness of glass. Clogging problems, costly compressed air use and the need for mist extraction equipment have been eliminated.

The scrap rate for the float glass line has decreased by 75% and consumption of the zinc citrate solution has been reduced by more than 60%. Maintenance time on the spray system has decreased from an hour each day to only three hours per month. These factors combined to provide a payback of less than one month for the AutoJet Spray System.

For complete details of this case study click here to see the PDF version.