Bakery Saves US$220,000 per Year by Switching to Regenerative Blower – One Week Payback

Bakery Saves US$220,000 per Year by Switching to Regenerative Blower – One Week Payback

Problem:

A large commercial bakery needed to improve its hamburger bun depanning system. High pressure air jets, powered by costly compressed air, were damaging some buns and failing to loosen others. This resulted in raw dough balls being placed in pans that were not empty. The cost of wasted product was approximately US$1,000/day.

In addition, the multiple plastic gooseneck fittings delivering the compressed air were prone to breakage. Whenever workers discovered a broken gooseneck, the line had to be shut down until all baked goods in process were inspected.

Solution:

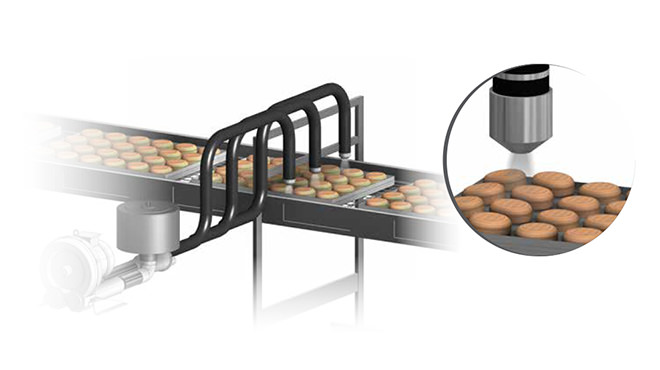

Spraying Systems Co.’s solution was a WindJet® Air Cannon package that uses three air cannons powered by a 3HP regenerative blower. The blower supplies low pressure air at a high flow rate to strategically located air cannons for quick, consistent depanning of all the buns.

With the reduced air pressure, buns were no longer being crushed in the process. In addition, removing the plastic gooseneck assemblies from the depanning system eliminated the possibility of breakage and ending up in a shipment of buns.

Results:

Following installation of the WindJet® system, scrap was eliminated. The bakery’s total annual savings, including compressed air, are projected to be more than US$220,000. The payback period on the new system: about one week. In addition, getting rid of the gooseneck assemblies enhanced product safety and reduced the occurrence of unplanned shutdowns.

Beyond economic benefits, changing to a regenerative blower system also improved the sustainability of the bakery’s operation. The bun production line no longer creates large amounts of wasted product, and the drop in energy used for depanning has permanently reduced the bakery’s carbon footprint.

The company has another bakery that is considering changing to this system, based on the excellent results obtained to date.

For complete details of this case study click here to see PDF version.