Cable Manufacturer Halves its Chemical Consumption with Automated Spray System

Cable Manufacturer Halves its Chemical Consumption with Automated Spray System

Problem:

A cable manufacturer needed to spray coating liquid onto a telecommunications cable in order to reduce the harmful effects its lead casing could pose to the environment. The previous spray solution, consisting of air atomizing nozzles, a siphon and compressed air, created a fogged atmosphere through which the cables were conveyed. This misting effect resulted in a significant waste of expensive chemicals as half of the spray solution evaporated in free air. Compounding this overuse was the fact that the spray required twice the amount of chemicals due to their dilution rate and the use of atomized air, which severely hampered the chemistry’s ability to neutralize the effects of lead poisoning. The air atomized chemicals also omitted a foul odor that made the work environment unpleasant for workers. All of these issues led to the need for a person to maintain the equipment on a daily basis.

The company required a new spray solution that would eliminate the use of compressed air and deliver an extremely low flow of chemicals. This system also would need to cut chemical consumption in half, eliminate any offensive odors and be transportable to multiple locations throughout the facility.

Solution:

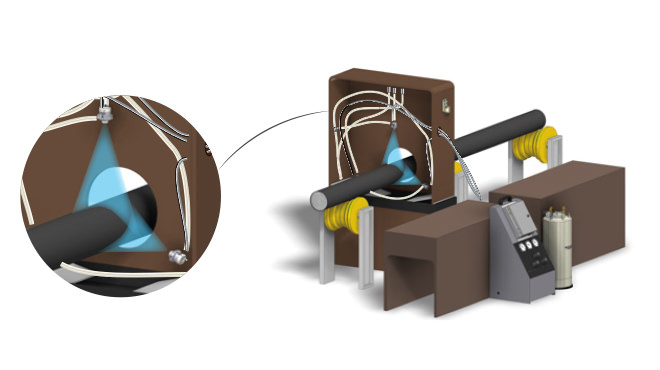

Following on-site tests to confirm spray coverage and repeatability of the chemical application rate, Spraying Systems Co.’s AutoJet® Model 1550+ Modular Spray System was chosen. The system featured an integrated, air-operated diaphragm pump and three PulsaJet® AA10000AUH hydraulic, electrically actuated spray nozzles. UniJet® tips were positioned at optimal angles around the cable to provide full coverage without excess overspray, and an enclosure was installed to prevent spills from escaping the application area.

Ideal for coating applications, the AutoJet Model 1550+ system ensured accurate placement of the liquid to minimize waste. The system’s Precision Spray Control (PSC) allowed the smaller PulsaJet hydraulic nozzles to achieve low flow rates, thereby maintaining pattern integrity and droplet size

Results:

With Spraying Systems Co.’s AutoJet® system in place, the cable manufacturer was able to address each of the issues it was having with the previous spray solution. The PulsaJet® hydraulic spray nozzles eliminated the use of compressed air from the system, increasing the transfer efficiency of the chemical over air atomizing by more than 50% and fortifying its effect on the lead casing. They also rid the production area of chemical mists and bad odors, leading to happier, healthier workers. The new system’s portability allowed engineers to move it to various production areas in the plant, and frequent manual monitoring and maintenance of the system was no longer needed.

In the company’s first year of using the AutoJet system, it was able to reduce chemical waste and subsequent purchases, energy to produce compressed air, and manual labor. These benefits led to a US$40,000 savings and a payback period of only three months for the total investment on the system.

For the complete details of this case study click here to see the PDF version.