Annual Savings of US$32,000+ for Pizza Crust Manufacturer by Reducing Oil Waste with Automated Spray System

Annual Savings of US$32,000+ for Pizza Crust Manufacturer by Reducing Oil Waste with Automated Spray System

Problem:

Tomanetti Food Products, a manufacturer of par-baked pizza crusts for more than 50 years, needed to apply oil to dough balls prior to being formed into crusts and baked. The oil prevents the dough from sticking to the press and adds flavor and color to the crust.

The existing system dripped oil from a trough onto the dough balls – a very messy and wasteful process. Tomanetti’s wanted to eliminate the mess and reduce the volume of oil used without affecting product quality.

Solution:

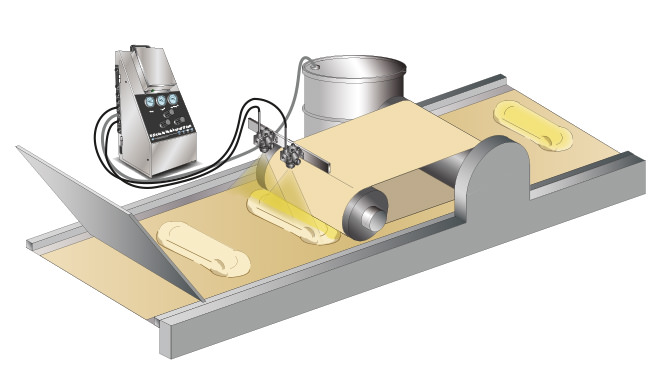

Spraying Systems Co.’s AutoJet® Model 1550 Modular Spray System with two AA250AUH hydraulic automatic spray nozzles solved both problems. The system uses Precision Spray Control (PSC) to spray a fine coating of oil onto the dough balls as they pass under the spray manifold. The oil is applied uniformly without messy misting or overspray.

Results:

The AutoJet® Model 1550 Modular Spray System enabled Tomanetti’s to maintain their high quality standards while reducing oil use by more than 40%. At a cost of US$8.50 per gallon of oil, the savings totals more than US$32,000 per year. The cost of the new system was recouped in less than two months. In addition, the precision application of oil reduced maintenance time caused by excess oil.

For complete details of this case study click here to see the PDF version.