Forest Products Decarbonization Forum

Listen to Justin Burger present on Carbon Capture, Spray technology & Computational Fluid Dynamics at Texas A&M University’s Inaugural Forest Products Decarbonization Forum

8

May 24

Full Audio Transcript:

Thank you. I'm very humbled to be here with everybody and really appreciate y'all's time and attention. You know, one of the things that we get to do is play in the world of spray and spray technology and a little bit about our company is, I tell folks, we're kind of the biggest company that you've never heard of. We've been around since 1937. And sprays are ubiquitous in many industrial processes, from laying paper, to the very semiconductors that run your phone, to the glass coatings on your glasses, to your iPhone, to the plastics and the polys that you guys are sitting on here. As well as cracking the hydrocarbons — many of you got here via gasoline or other mechanisms, and when you switch to batteries, we'll be there too. So we're kind of ubiquitous, very unique, and we're all over the world with several manufacturing locations throughout the world and several technical centers as well. So we pride ourselves on the technical capabilities at each of our offices here. So today we're going to talk about several topics and I'm going to move very, very quickly because there's a lot to go over. So some of the topics are going to be the why, why do we care about spray technology? Why does it matter? The DNA of the spray and the types. There are several different types. Our catalog includes over 150,000 unique SKUs.

Whenever you think about sprays, we're already a niche company, but to be a niche company with 150,000 SKUs, is significant. So I'm going to go through that DNA, I'm going to go through energy consumption examples, and then from there, I'm going to share with you some early carbon capture explorations that we did. We got bored in the lab and we actually created our own carbon capture technology because we were just curious and we wanted to play around and see, hey, how does a spray interact with actually capturing carbon? Do I burn more carbon than I should to do the requisite capture? So we got down to the fundamentals and it's kind of fun, particularly when you hear all the politicians getting after it, it's really fun. And then from there, I'm going to go to computational fluid dynamics and how that may be impactful for some of the work that you may be looking at and some of the key insights that might be able to be there for your processes. Then tank cleaning, and then innovation technology, and then we'll wrap this, wrap this all up.

So the why — one of the things that was interesting to me is that we're starting to live in what we call an electromagnetic era, right? Every electron matters. Every single electron matters. Whenever it comes down to energy transfer, moving bits of information, all of those things — sprays are instrumental to that from the power gen side to the gas conditioning, all of those aspects. And so, one of the premises that I work off of is that each electron movement serves a purpose. And then our purpose is to ensure that each electron movement brings the most value as it relates to spray technology. So when we get down to those fundamentals, things get really, really simple & exciting. And so that's kind of the why behind why I'm here.

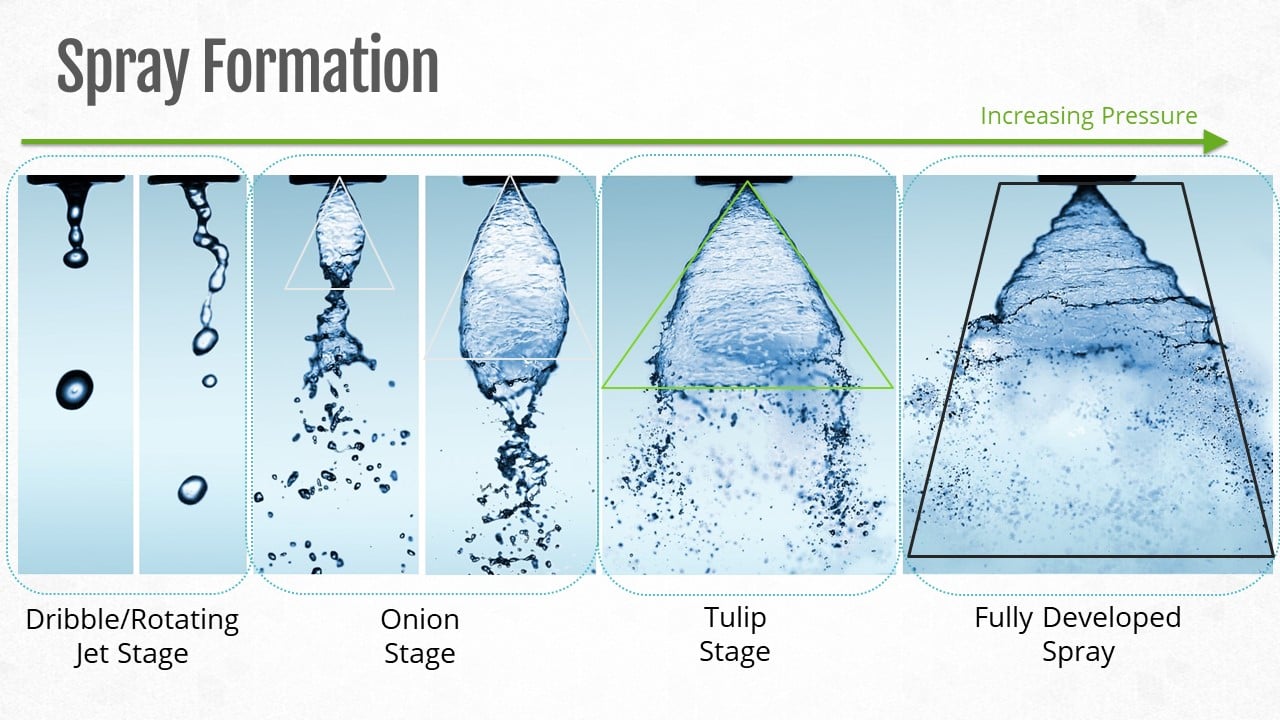

I'm not going to spend a lot of time on the technicalities of sprays, but it's just interesting to look at it. And whenever you see, these distinctions through here, right? Going from that dribble stage, adding a little bit of pressure, you're breaking up that surface tension a little bit. One of the fascinating things is there is no one single droplet size. And so when you have a distribution, that means that you have a lot of uncontrollable physics that are happening within your plant. So a lot of times y'all are using sprays and you're spraying. I've come to learn quite a bit about sprays and whenever you multiply that distribution, that's a lot of variability in your process. So variability in your process means there's opportunity. And so as we move, we increase pressure, you can see we can get down to a fully developed spray. As you look at this on the macro scale. I mean, these are all very distinct and different droplet sizes. And so, we move through each of these phases and you can just see how that progression moves.

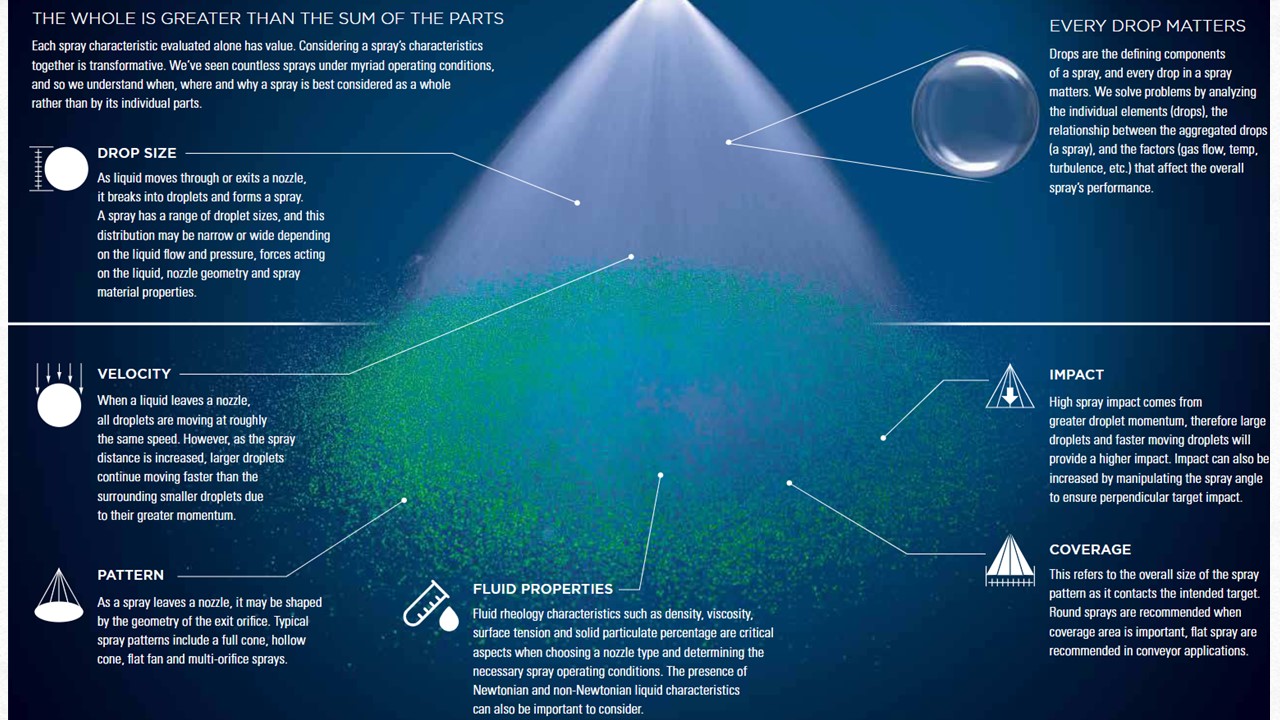

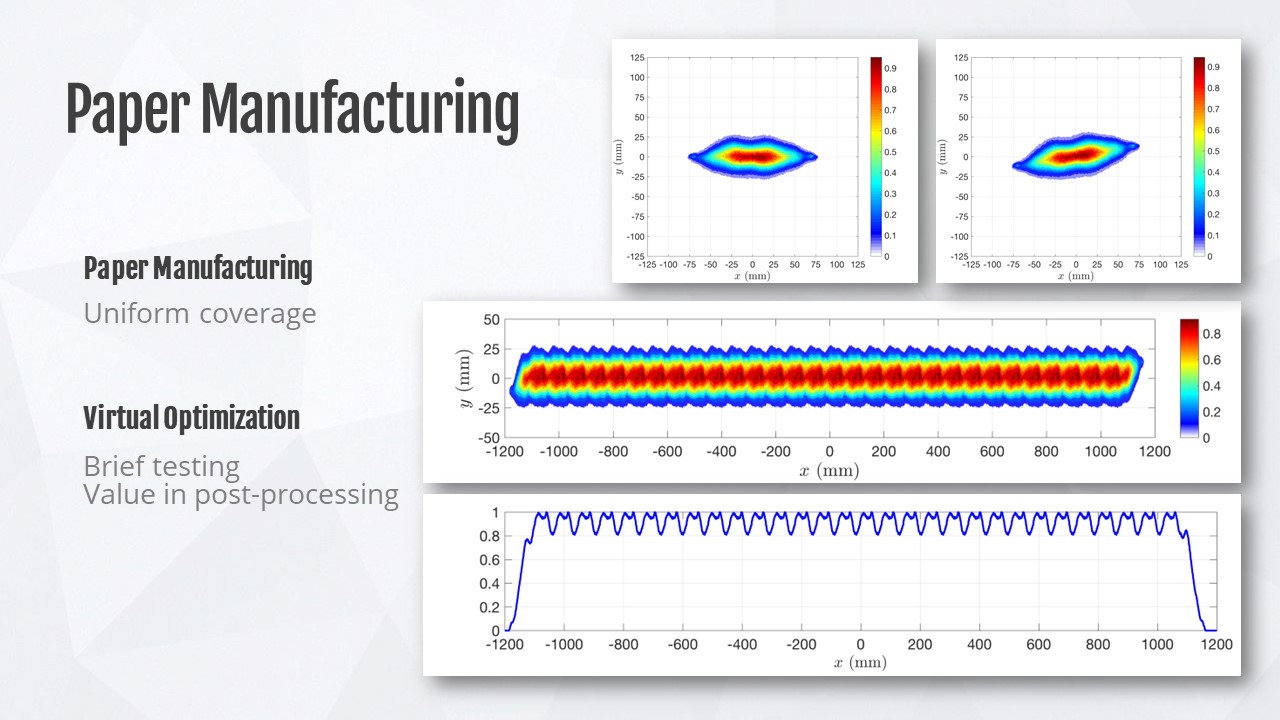

I like this slide because it really goes into the key facets that we look at. In the paper industry a lot of the things y'all are looking for is really coverage impact. You do some chemical processing I've learned which is kind of cool because I spend most of my time, I'm out of Houston, in the chemical refining aspect of things. So we understand out of our office, quite a bit about that and why sprays and surface area are pretty important.

What's also important for y'all is that velocity. Your paper is moving at a very, very fast pace and with that fast pace you have a very fast and high boundary layer. So if the drop sizes are too small, they won't even transfer to go where they need to go. If they're too big, then maybe that causes other issues. So it's kind of like this. It's got to be just right. And so, you know, we look at that drop size velocity, of course, the pattern matters because with that pattern it's going to impact all of those things.

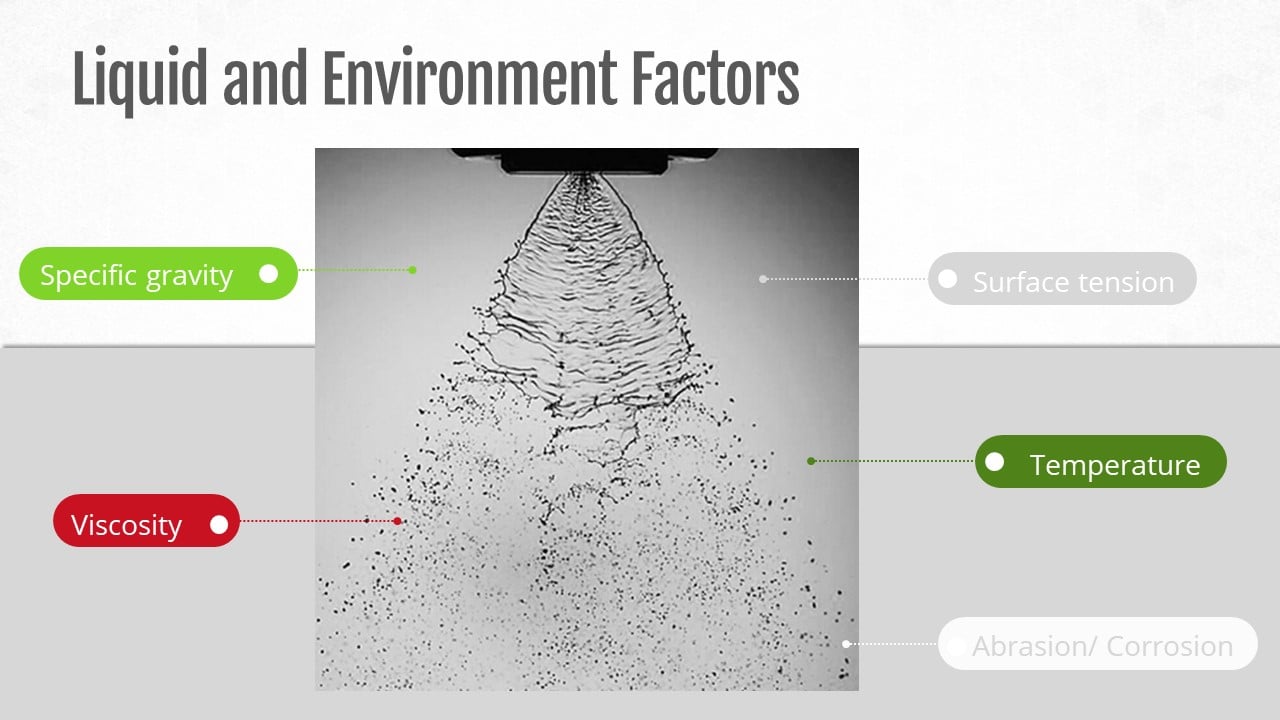

And then from there, we go to your fluid properties. So everything in our catalog is water. Everything's water-based and 99% of the time, our customers are not spraying just water. So it comes down to that intuition of okay, what actually works you know with your process and then how do we get down to the fundamentals of what that actually means? A lot of times customers say, "hey, I need 30 gallons a minute. 40 PSI." And they're like, "oh just assume water." We've learned that water behaves way differently, even if you load something. And so with that difference comes a lot of value, I've learned. And again, just kind of hitting down to that point. Some of the key factors that we like to consider, you know you have specific gravity, viscosity, surface tension, temperature and of course abrasion becomes another aspect in your process. The faster the nozzle wears, the faster, it gets out of spec. The faster, it gets out of spec, the more energy you're going to expend. The more energy, you expend, the less profitable you are.

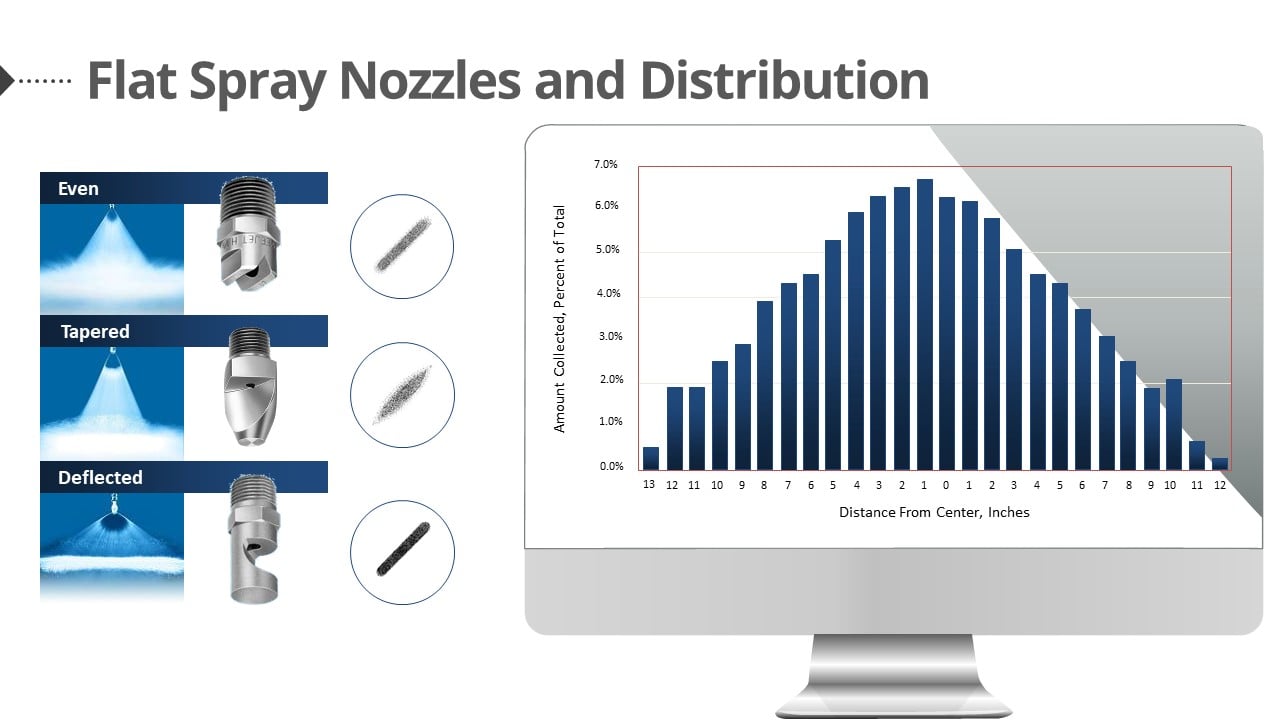

And so with that, we've got several different styles of nozzles. So out of our 150,000 nozzles that we have I'm breaking it down to just the very succinct groupings. So you can see here, we have our even with our flat sprays. You all use that a lot on your web lanes and all those other aspects. You've seen them across the board and getting those distributions just right, it becomes pretty important from a quality control side of things. We have a tapered and a deflective version. All of these, I believe y'all have in your plants in one way, shape, or another. And they produce a distribution. There is no one nozzle that creates one drop size. They're all gonna have a distribution of some kind, which means variability.

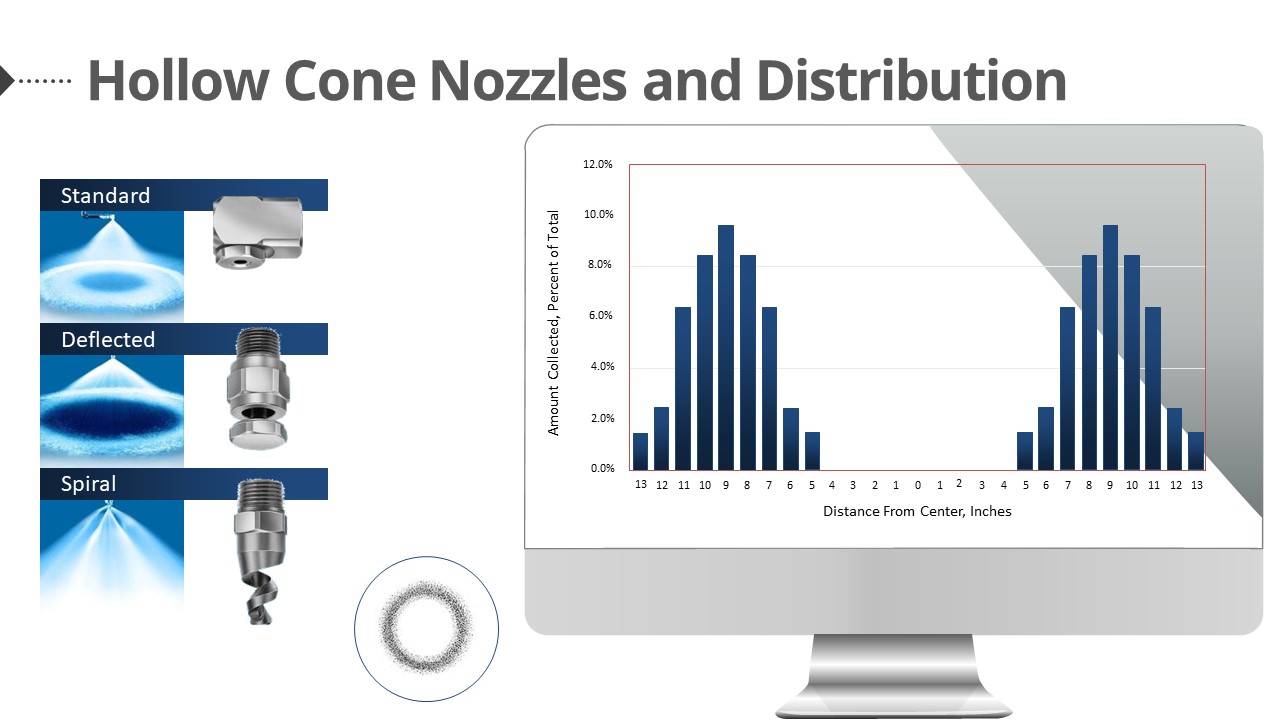

Then you have the different hollow cone nozzles. These are good for gas conditioning applications, where you need smaller droplets and smaller droplets are really good because they generate surface area, and by generating surface area you can do chemical reactions, heat transfer, all of those things that become very important. And with those distributions, you have a whole menagerie of different styles. Right here it's kind of a creates an air core or a tornado. If y'all ever get the chance to come out to our facility out of Houston, you can actually see it — you can feel the spray, which sounds kind of funny. But with these types of nozzles up here, you can actually feel the low pressure region that it's created. You can feel it, actually sucking your finger up into the process which is kind of neat. When you can feel that you can actually say, oh, wow. Well, what other implications does that have in my process so you get that intuition.

Then you have the different hollow cone nozzles. These are good for gas conditioning applications, where you need smaller droplets and smaller droplets are really good because they generate surface area, and by generating surface area you can do chemical reactions, heat transfer, all of those things that become very important. And with those distributions, you have a whole menagerie of different styles. Right here it's kind of a creates an air core or a tornado. If y'all ever get the chance to come out to our facility out of Houston, you can actually see it — you can feel the spray, which sounds kind of funny. But with these types of nozzles up here, you can actually feel the low pressure region that it's created. You can feel it, actually sucking your finger up into the process which is kind of neat. When you can feel that you can actually say, oh, wow. Well, what other implications does that have in my process so you get that intuition.

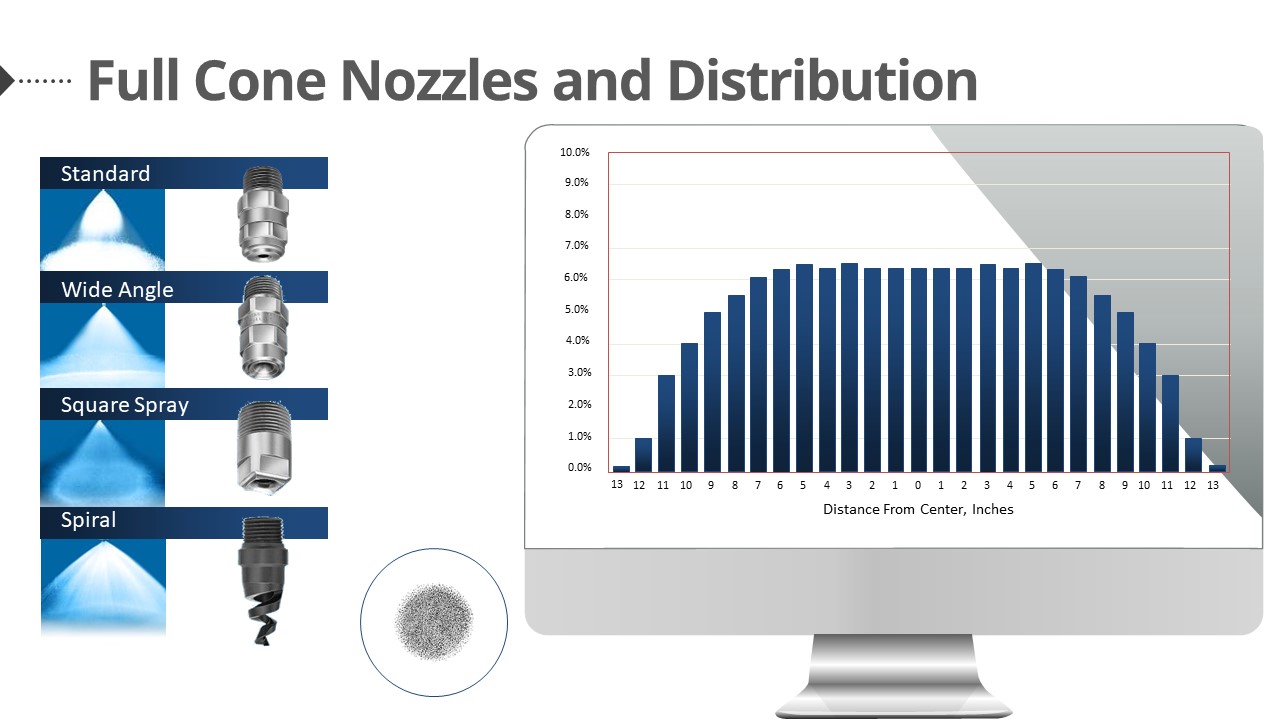

And then you have your full cones. Again you might see this in your scrubbers or other applications, but what's neat about y'all's industry is you cover almost the whole gamut of spray nozzles that we utilize and that's pretty powerful.

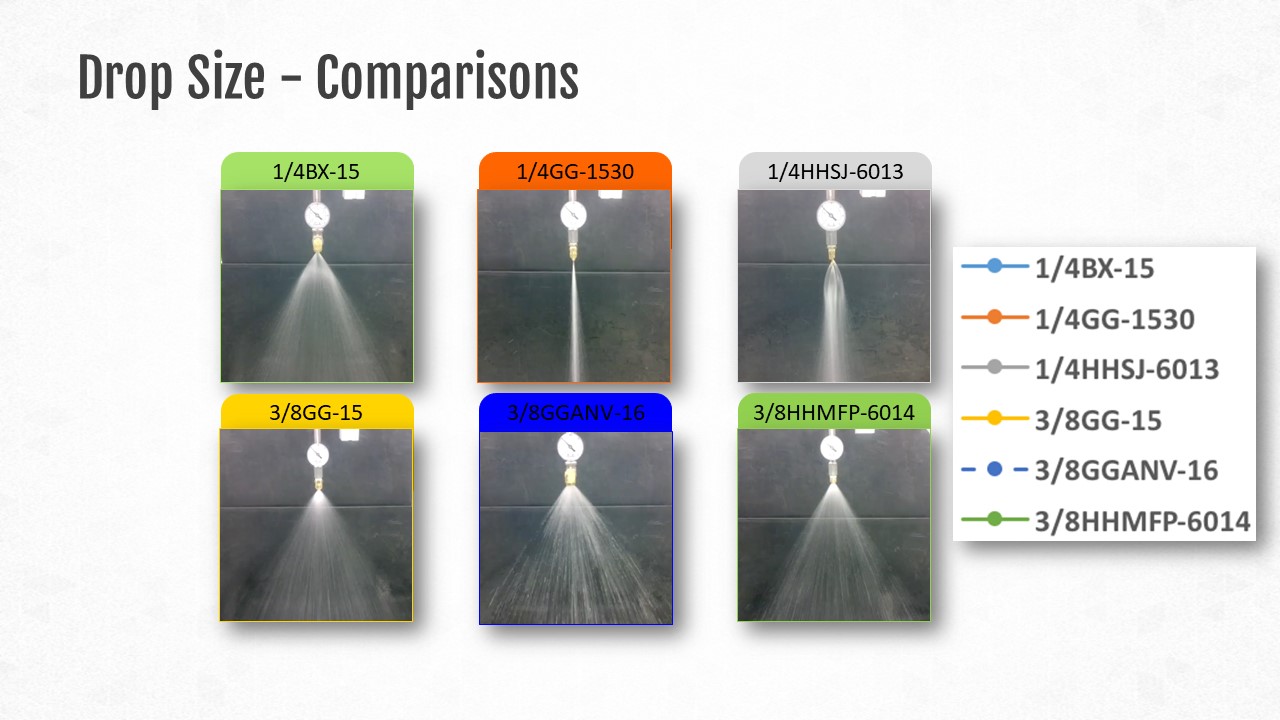

I like this slide. So these nozzles are actually spraying out of our lab. And they're all spraying at the same pressure and pretty similar flow rate. You can see how vastly different each of these look. This one kind of dances around a little bit. This one has a little bit more even spray distribution. But you can imagine this spraying hundreds of nozzles or thousands of nozzles. That each of those iterative pieces or those streaks that you see can make a real big difference. Particularly, if you understand where they're going, or how they're being produced, how they're propagated and the amount of energy it takes behind to generate this spray.

This again, is our facility, so there is no nozzle that will never clog. Any nozzle will clog, no matter what. Even, you know, the greatest nozzle design in the world, it'll clog. I was working on a [project], it was some kind of bioreactor. And the nozzle was about this big and somehow, Vernon I think you knew about this one, and there was a, there's like a soccer ball and all these other things like stuck in that nozzle. And I don't know how it got through their filters or processes, but [the equivalent of] a whole soccer ball stuck in between the nozzle and they were, "hey, what's wrong with this thing?" Send me a picture of the nozzle. Soccer ball — that's the problem. So what I'm showing here, is this nozzle optically. Whenever you're in your plants, a lot of times the engineers will say, "oh yeah this nozzle is good" and stick it back in the process after it's been cleaned. Because if you only saw this side here and that's all you knew you're like, "oh, that's a good nozzle." Right? But if I told you that this was spraying 50 percent of the capacity of what it's designed for and then think about the energy costs and utilization that goes into that and that's just one nozzle. And so we're kind of going through this story to understand the energy balance and that the energy that it takes to create a droplet really, really matters within your process. There's a lot of optimization opportunity.

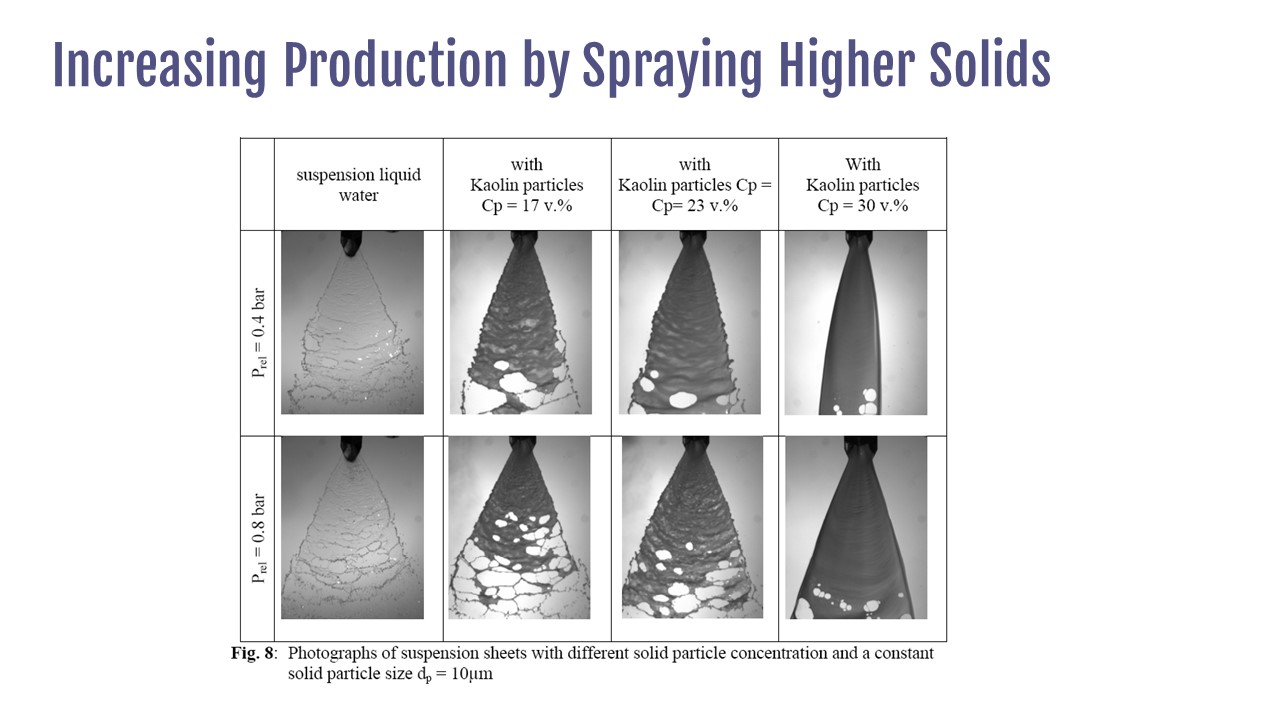

So, with that, we're looking at another aspect and just providing you the mental models of how water may be different whenever we start increasing the viscosity or particulate in flow. Right. So all things being equal, we're at 0.4 bar here. Moving from left to right, look how different that spray propagation is. The difference is significant. So you can see how it takes more energy as that viscosity increases, your spray angle decreases and all of those things. So, when you're talking about your TDS, or your water quality, or all of these aspects the spray pattern can be kind of whatever you want it to be at that point, right? It's all — There's so many variables here. And the same here, you're at 0.8 bar, you can see, I still get a wider spray pattern. But as I get down here, I get hardly any sheet breakup, hardly any droplets. And that's, that's pretty interesting. Whenever you go, "Oh yeah, it's just water" well we kind of know better when a customer says, "oh we're just spraying water", what are you really spraying? Because then we can kind of get to this level of insight here.

This is just for fun. I'll let you all absorb this for a little bit. I always ask this question what are we noticing or what are we witnessing here? Anybody know the phenomenon that we're seeing? What's that? Oh, uh, Leidenfrost. Oh yeah. So we're at 239. So 239. Leidenfrost. Right. So this is the impact of temperature on one singular droplet. This one droplet — and you guys are spraying thousands of gallons almost per minute, right? So whenever we think about this from a heat transfer side of things, this becomes very, very powerful for y'all to hold in your minds. Right? So this is a heated surface. Again, just watch this. Let's just pay attention to right here. 179 degrees C, what's happening? Yes, it's evaporating, right? What's happening at this 239? We're at the Leidenfrost regimes. Well, what's happening to that droplet? What do you — what characteristics do you notice, which is way counterintuitive probably to what you would think? Hotter temperature — water temperature. Get a little bit of heat transfer, now, I want you to compare these two. Right? Number one, all things being equal, the velocities were the same, what's happening inside of this thing, and then watch the ricochet. It's all about the fundamentals. See how this one just keeps bouncing. It hits that vapor barrier and doesn't even transfer. And again I just share this as again to kind of open up our minds a little bit that there's so much that we don't quite comprehend yet at the fundamental level. And whenever we just ask the right questions, maybe we can get a little bit more insight into how to use our resources, very, very wisely. So again, nothing to do with any of your applications, other than I like to have fun with that slide here every so often. Another aspect is we're working on these tools, right? So I've learned that there's a cycle and it kind of goes from macro to micro, macro to micro and everything goes into the cycle. So what was macro, big, suddenly you get down to the fundamentals, it becomes micro but then you understand that so, well, it gets big again.

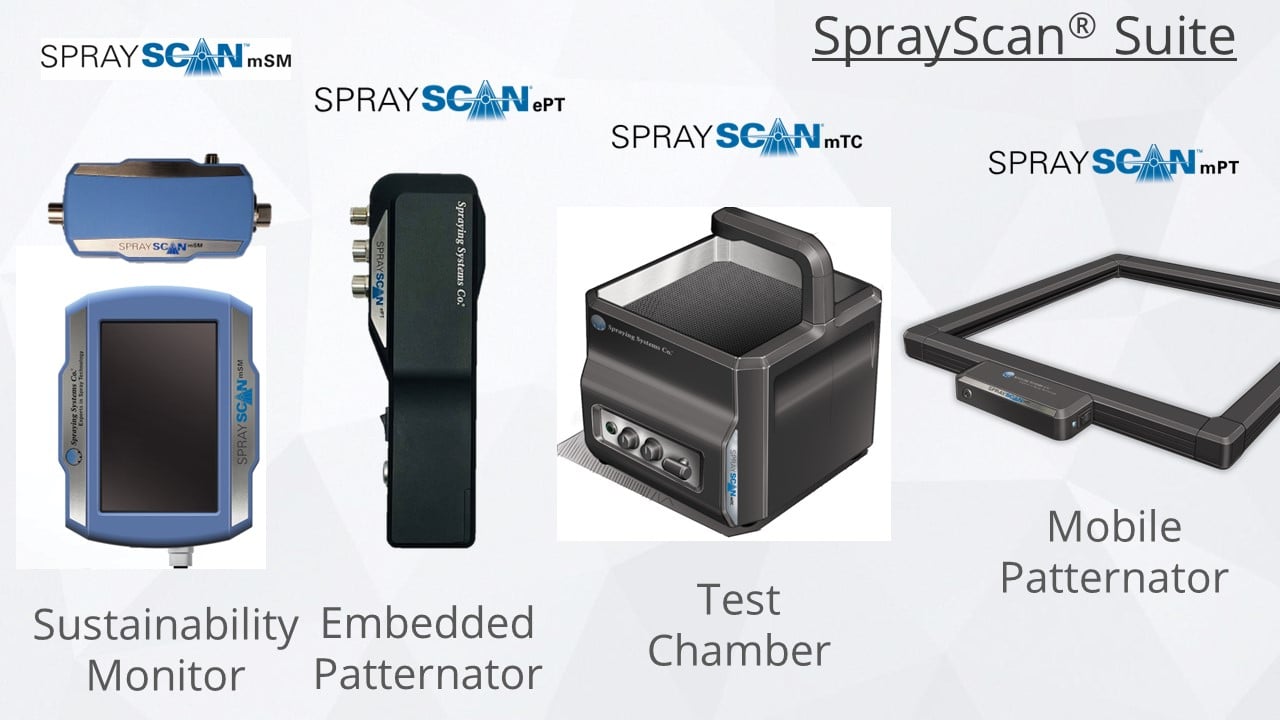

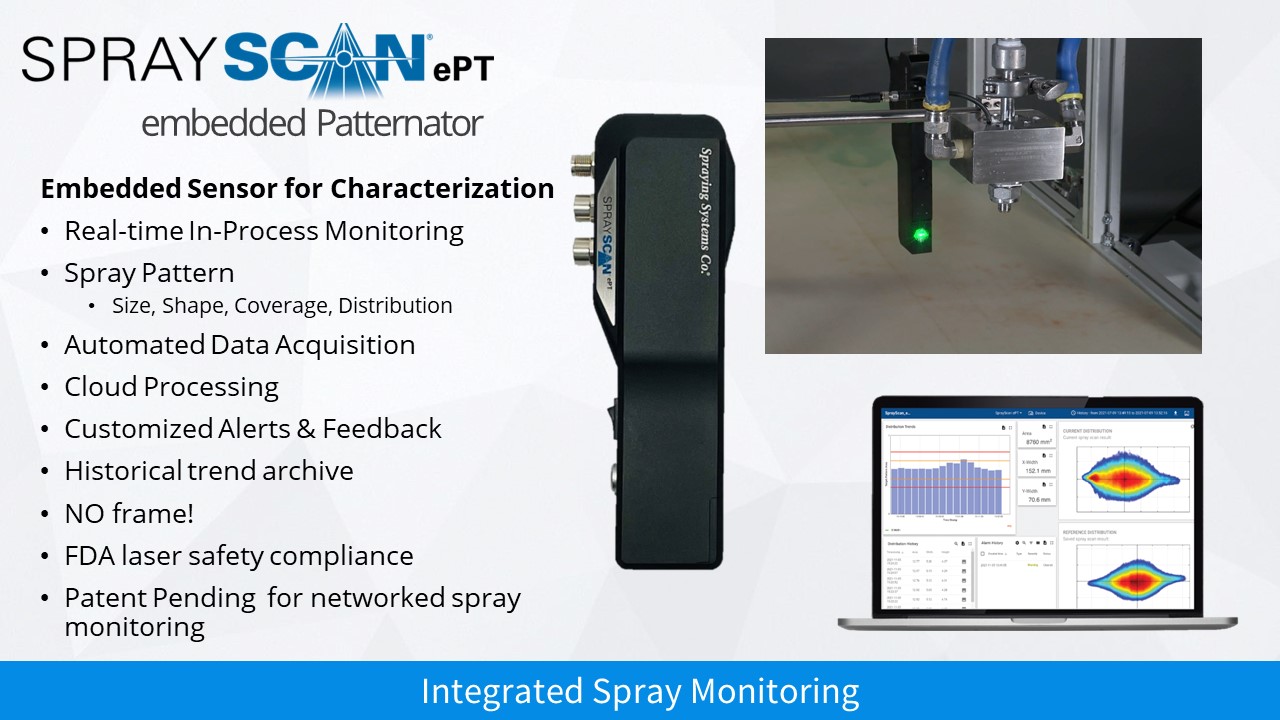

And so what we're showing here is a new tool. So we're working to democratize data and information. And what typically takes a PhD and a lot of hours and setup to monitor. And to understand the fundamentals of what's happening, we work to package into something very small, very simple. So you can actually potentially get in-situ measurements of how your spray bar is performing online optimization. Getting those indirect measurements to understand what's happening in your process and get greater control. All we're showing here is that heat map that was produced by that device right there. Online and we're optimizing for the distribution. Now again, the measurement's not of the quality of, you know, your Malvern or particle size analyzers, but it's a democratized version to get you the mental concepts that you need to optimize the process yourself. You don't have to go get a PhD to run these things. You can start getting this data today and optimize your processes. And I think that's one of the very powerful pieces that our CSO is so important about you know, it's not about the money, it's about democratizing information and getting it into the customer's hands.

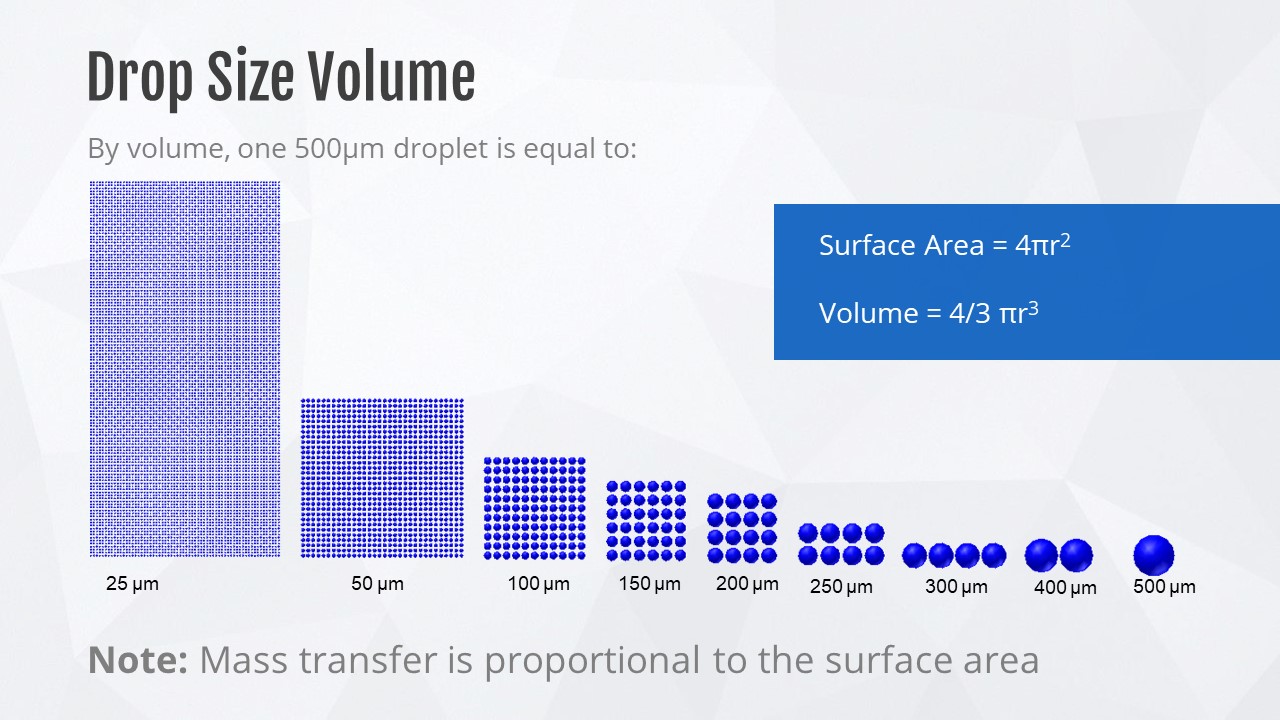

And so the next phase that we're going into is, why does drop size matter? You know, what's the big deal? And this chart really helps me kind of get down to what you're what we're looking at. And in your plants — sometimes you might be cooling something or you might try to facilitate a chemical reaction. If I'm trying to facilitate a chemical reaction, do I want 500 Micron droplets or 25? Which one? 25 Micron. I have my chemistry doing a lot more work over here. Right? It's not just this linear scale, as we get down to smaller fundamental droplets. I mean, look at that for difference, right? So you have your surface area, πr2 and then your volume πr3. This visual is very, very helpful. So if your spray distribution is off by a small fraction of a percent and you're using money for your chemistry and all these things. Well, if you shift from 25, Micron to 50 Micron. Well, you have a lot less molecule interactions doing the work that you would expect for it to be doing. It's that mental model that provides a way large amount of value if you can kind of work through those problems.

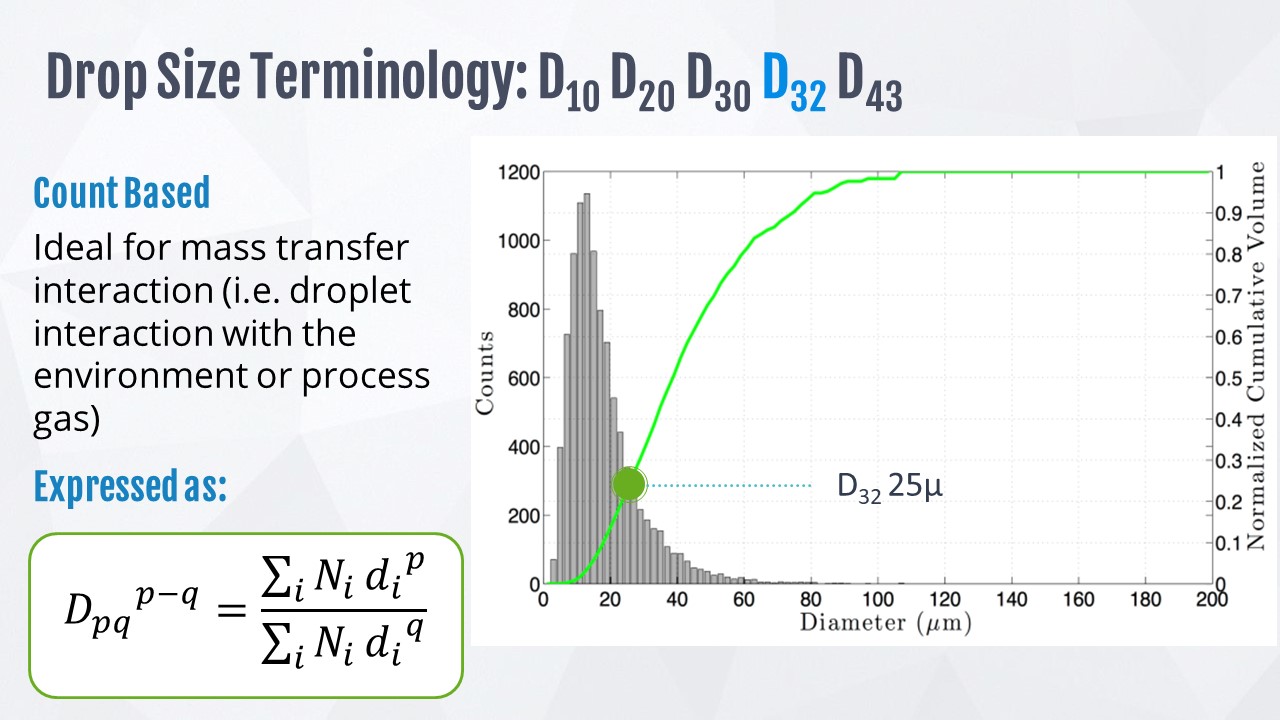

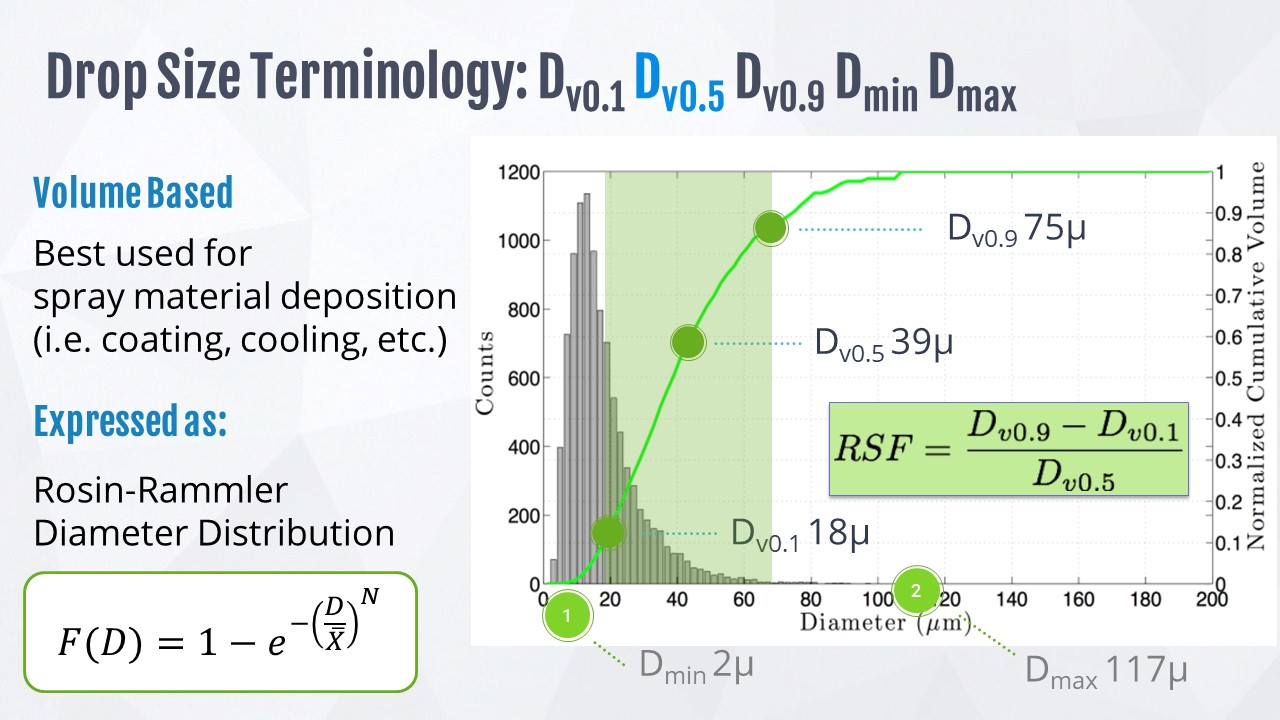

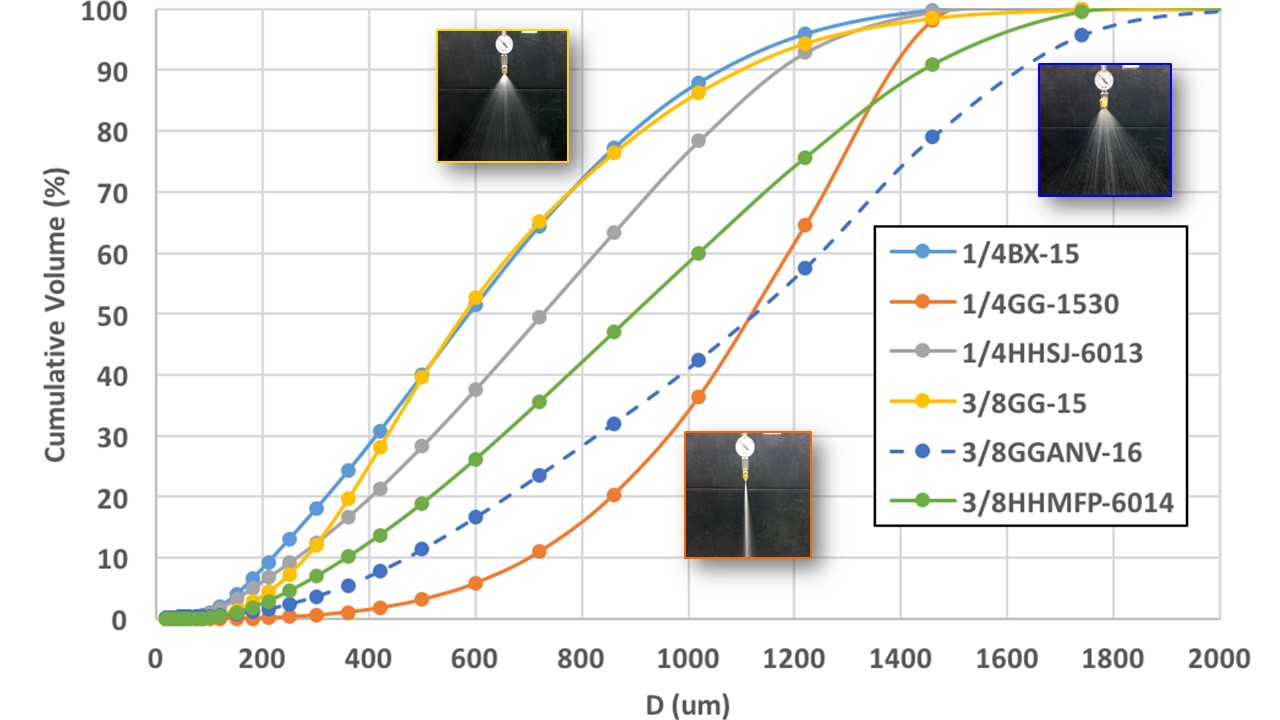

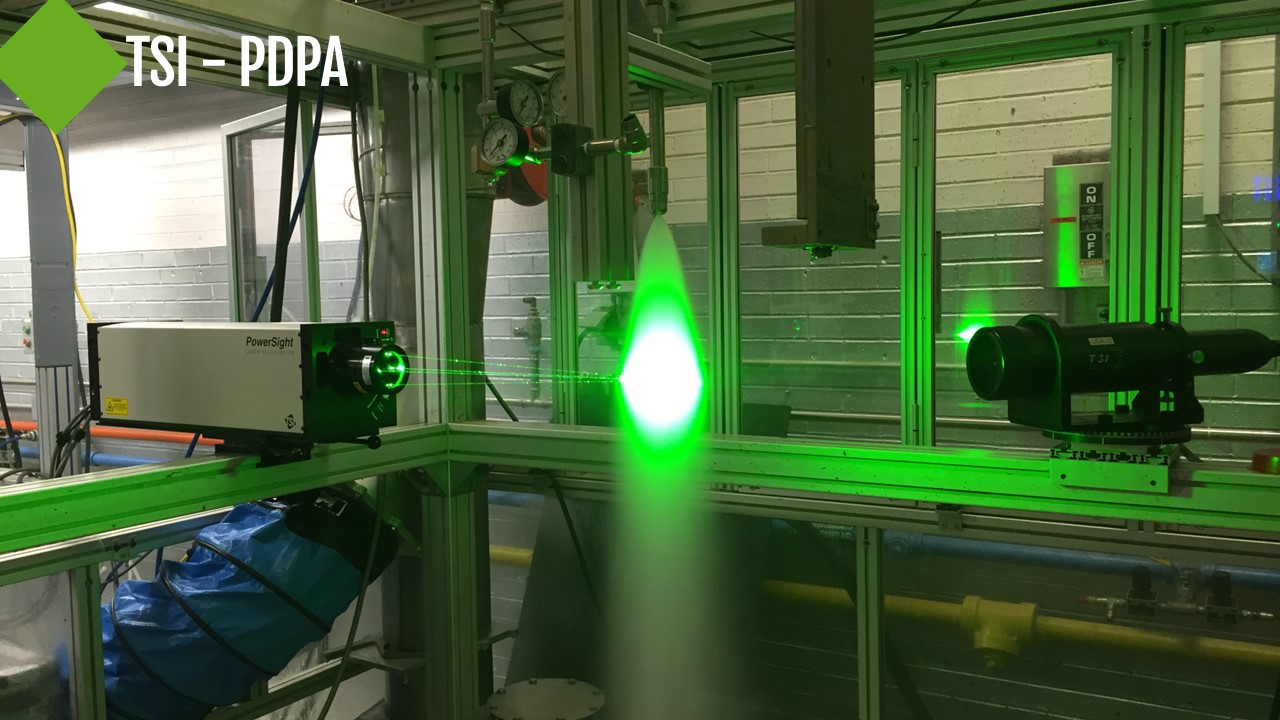

I'm going to speed through drop size terminology. But, you know, I spent some time, this is inside in our lab. We were running some experiments and I never really dealt with drop size too terribly much, because we always just accepted the data. But I got one at our lab and I measured, it took 300 measurements in the course of one day of a drop size. After that exercise. I learned, you know, you can make drop size be whatever size you want it to be, depending on who's measuring it and how you set up those measurements and who you ask. I mean, there are so many variables that whenever you receive drop size data. There's a lot of questions that could be asked, unless it's coming through, from a, you know, a certified lab. I was shooting from the hip trying to get fast information, but then I really learned the intricacies of, wow, there's a lot to a lot to understand here. Here, you can see. We've got the counts, you've got the volume, you have, all these statistics that go into it dv10, d50, d90 the max, the min's, all of those aspects, and it's just a way for us to communicate. Well what drop size we're working with. And again, not only communicating what drop size you're working with. But where is that data coming from? It's very, very important. It takes very specialized equipment & specialized PhD level folks to really get a very accurate repeatable measurement. So that's really important.

So you can see my dv10. Meaning 10% of the droplets are 18 Micron or below. Dv50 right in the middle 39. So 39 Micron size. So 50% of my droplets are that size or below and then whenever you get to your D-Max, And 75 Micron and below. So this gives you your boundary conditions to work off of. So you can say hey the maximum droplet I would have is X and then that can mean a certain thing for your process. And this is actually pretty important to your rsf (relative span factor). So that's how tight your distribution is. So depending on what you're looking for, it's really not a good or a bad thing. Sometimes you might want a wide distribution of droplets, sometimes you might want it tighter. So all we're taking is your d90, dv10 and dividing that. That gives you how far apart those droplets are from one another. And so that's an important metric as you start going. You know, if you start talking to somebody about drop size, say "hey, what's your rsf?" that's an important piece to understand to understand that relative span factor and what importance that brings.

So now we go into the other aspects of it. So this is really good for mass transfer. And I'm not going to spend a lot of time here, but it's just another piece of vernacular, and how we can measure. These droplets d32 is a spectacular number to work off of for a mental model standpoint. And again, we could just go through that process very quickly.

This is a nice piece so all the exact same — similar — I should say flow rates. But you've actually got different style, nozzles. So not only are these nozzles spec-ed in, let's say, two gallons a minute at 40 PSI. You notice that based on how that nozzle is designed they actually produce a pretty wide range of drop size. And drop size is very dependent on your pressure drop So pressure drop, drop size. All of those things, add up to your parameters. If you increase the pressure a little bit with a hydraulic nozzle, Typically, you're going to expect a little bit smaller droplet. Okay. If you reduce that pressure or that nozzle wears out and you're keeping your everything, the same, your droplets are going to get bigger. So, it's very dynamic whenever you're looking at your various processes and also, it's incumbent on the actual spray nozzle that you're utilizing.

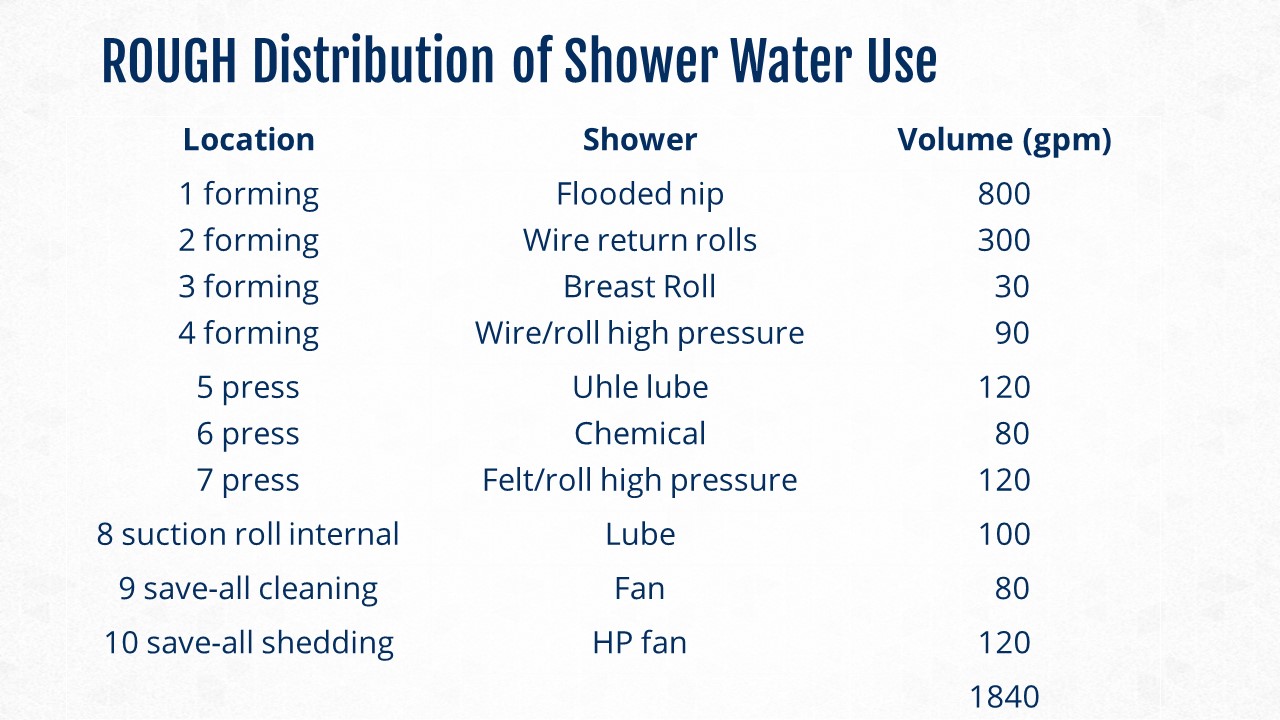

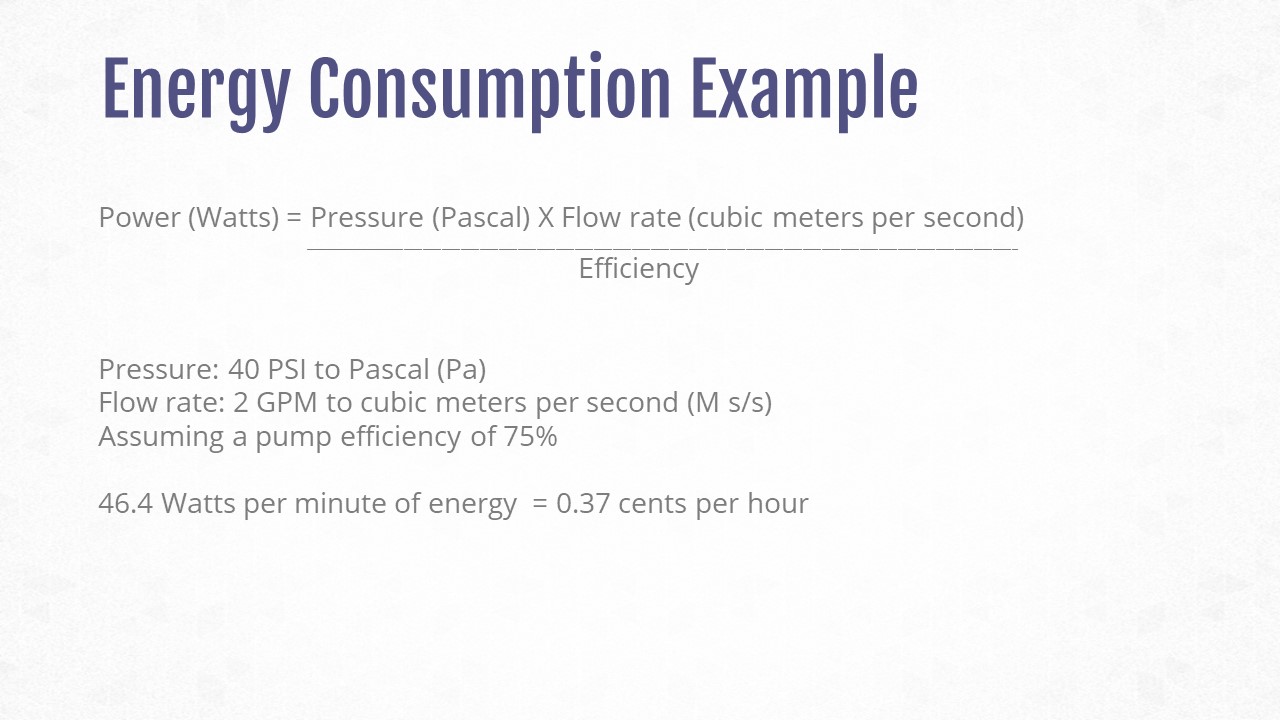

So I'm just going to go through an energy cost example. And again, don't take this, you know. Take it with a grain of salt. It's just a conceptual piece and Brian Moran, helped me grab some of these in the back here. Some of these numbers — he's been in these plants, several of them and we've done some of these energy audits and all these aspects. So, you know, again each plant is different but it gives us a good idea of what the flow rate you're looking at.

So, I just thought this was fascinating. You know, the level of gallons per minute that could be flowing through your plant. And then whenever I thought about all the droplets and then I, you know, I painted this picture of all the dynamics that are happening. I'm like, oh my goodness. We really don't know much of anything. It's kind of what I thought, whenever I looked at this. You know, you've got all of the forming, you know? Look at all those gallons 1,840 gallons per minute. And those of y'all, on the upside, would you say that's a fairly accurate number?

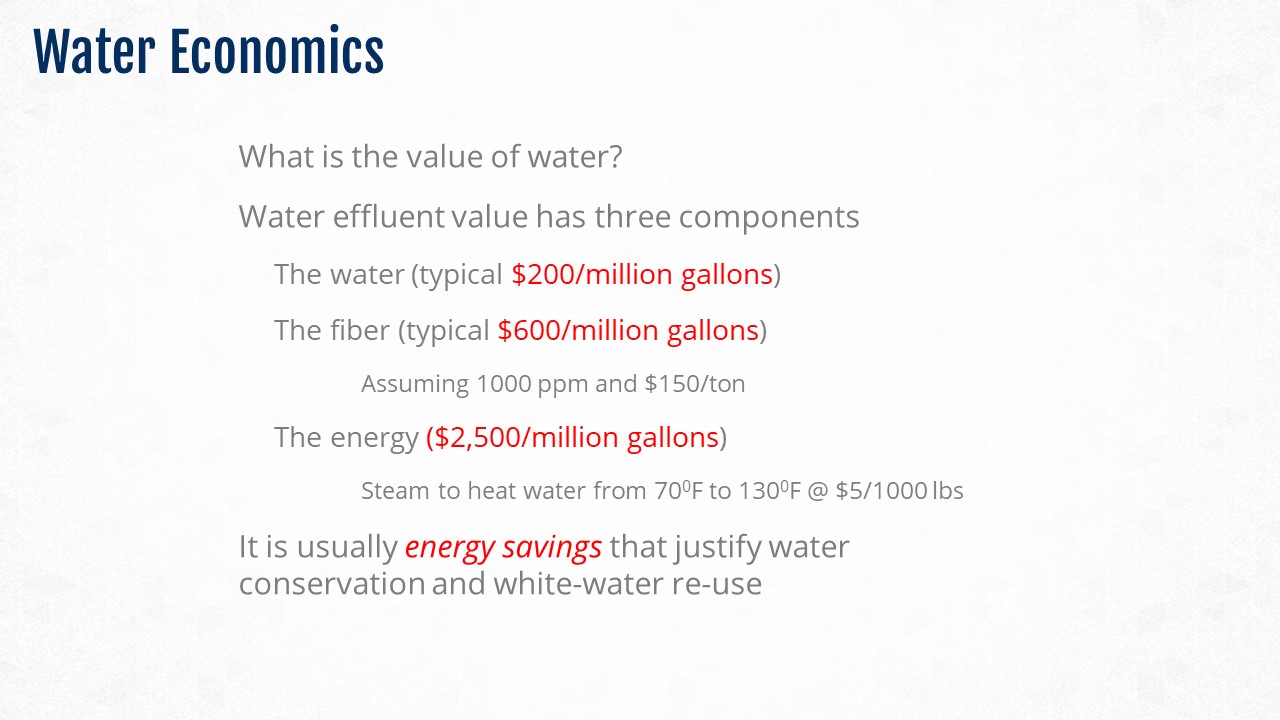

Okay. And again we're going down here so you know looking at what's the value of water? The effluent and the components, you can see that the dollars can start adding up pretty significantly.

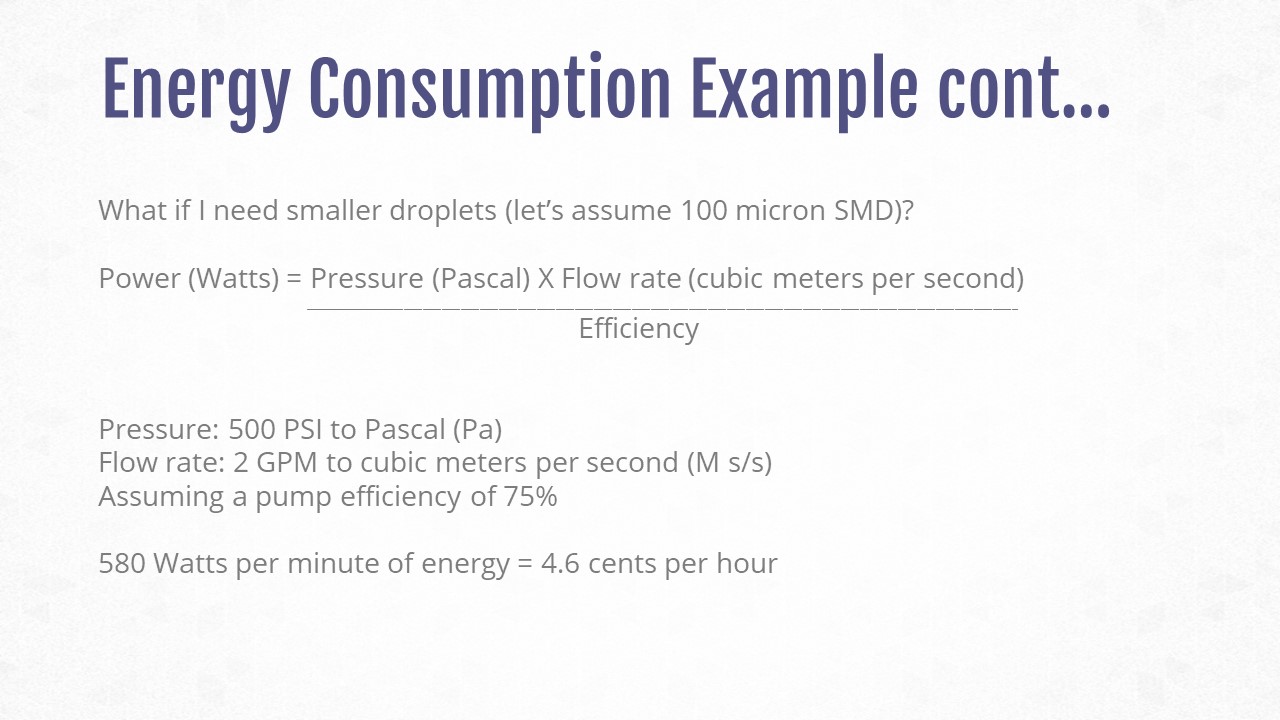

And then I went to the next phase. And this is the formula that I was using. And again, this is going down to one nozzle. And just trying to get a baseline. I want to get down to. Okay, what's the cost assuming x amount of pump efficiency? Spraying at 40 PSI 2 GPM. What does that cost per hour? And so what I learned is, okay, rough math that's 0.37 cents, per hour, not a lot. Um, but whenever I flip it, and I say, hey, I want really, really small droplets and I have to put a lot more energy into it. So remember this number 0.37 cents.

And then I all I do is I change and I say, "hey, I want 100 Micron droplet again." This is all theoretical stuff. Um, still flowing through GPM, but my pressure increases Look how many more cents per hour. We're spending on just that one nozzle. So you're at 4.6 cents per hour, and then you can multiply the 1,800 GPM times, 60 times that number. Then you can start getting an idea of just the cost from a watts standpoint of just moving the water. Not processing it, not doing this and that, and the quality control issues. I didn't do all that funny math, just because um, I wanted to get it down to its to its rudimentary pieces here.

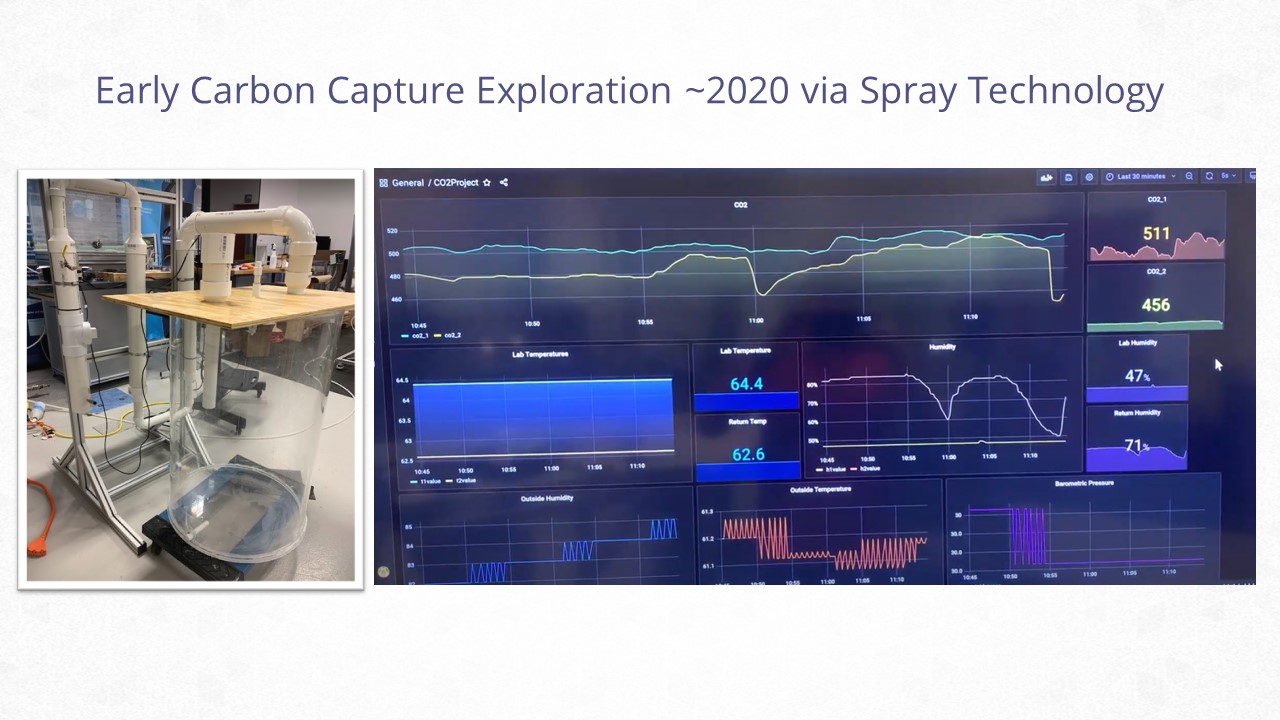

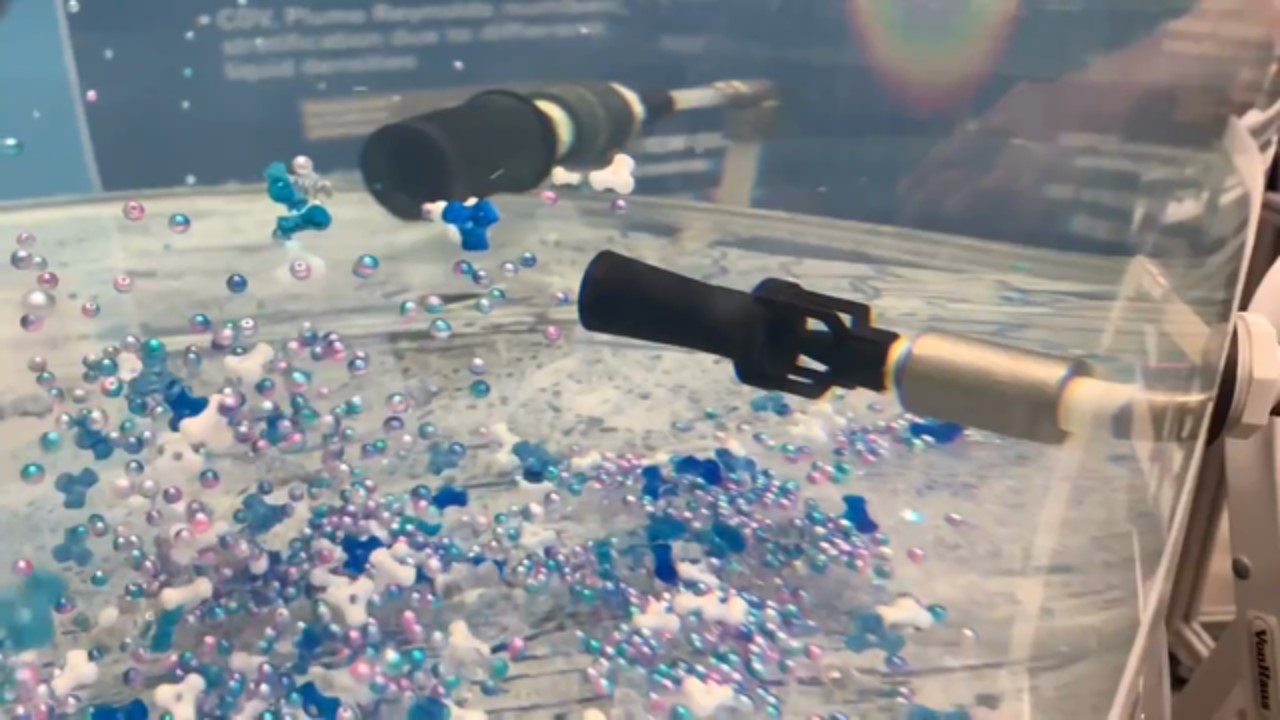

So transitioning, you know, this is a decarbonization aspect of it. And I just want to share a little bit about our early experiments here. And, thinking are we good on time? Still okay, great. So this was my homegrown piece where we we hooked it up with analytics, we did two fluid atomizations, NaOH inside of a 400 PPM lab environment. And we discovered that with the two-fluid nozzle, creating the droplets that we needed to create we expended more carbon on the pump work than we did on the spray to capture carbon and directly in the air. Which is to be expected, but I was a bit hard-headed and I needed to actually feel the numbers myself, but we learned a lot through this process.

Number one, if your CO2 levels are pretty high, the sprays actually work really well because your molecules can match together, but a direct air capture solution it's pretty rough to do via sprays because the energy costs for pumping are so high. But that being said, as your PPMs go up or NOx or SOx control, our sprays are already there, spraying the amines, ammonia, all of those aspects. When we do that we create very, very small droplets. We're probably already in your plants. You may or may not already know it, but a lot of those auxiliary controls — we're there. And the nozzle maintenance aspect of that is very important to make sure you remain in compliance. So if the nozzles are off, if you're over-atomizing or under-atomizing, you can get slippage, meaning the droplets are escaping and your demisters can't catch them, or they get too big and you're not able to control your emissions — whether that's on your turbines on the natural gas side or on other aspects. So again, I was just sharing this aspect of it because it was fun and we spent quite a bit of time just understanding that diffusion layers and all the molecules that went into it and there was a lot of fun there. But what I will tell you is it is being used. We are involved in the direct air capture side of things but also in liquid to liquid injection.

A lot different than spraying in the atmosphere, we're actually injecting liquid to liquid creating that surface area. That has an energy balance that actually works. And so, just sharing some of the fundamental work that we've done in our facility. And this is another aspect for, if you have your own power plants, with turbine inlet cooling, we can actually spray cool the air on the inlet of your engine and we can densify that air and you can goose a little bit more optimization out of it as well. And so, the wet bulb, right? Humidity, all these things have to go into play. But if you're in this territory here, not on the Gulf Coast, you could probably spray a few more days than you wouldn't. And that offset would be there. You can get a pretty good amount of performance increase.

And so that's what these pictures are here and some of the analytical tools that we get to play with.

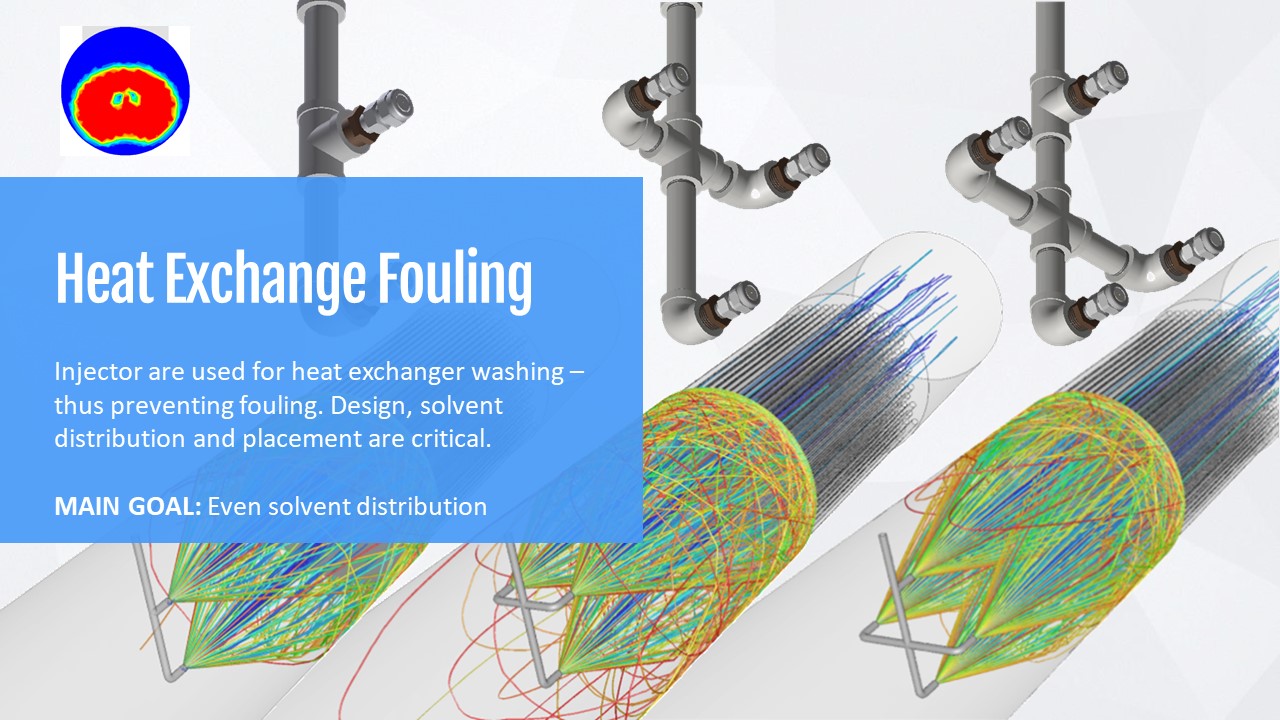

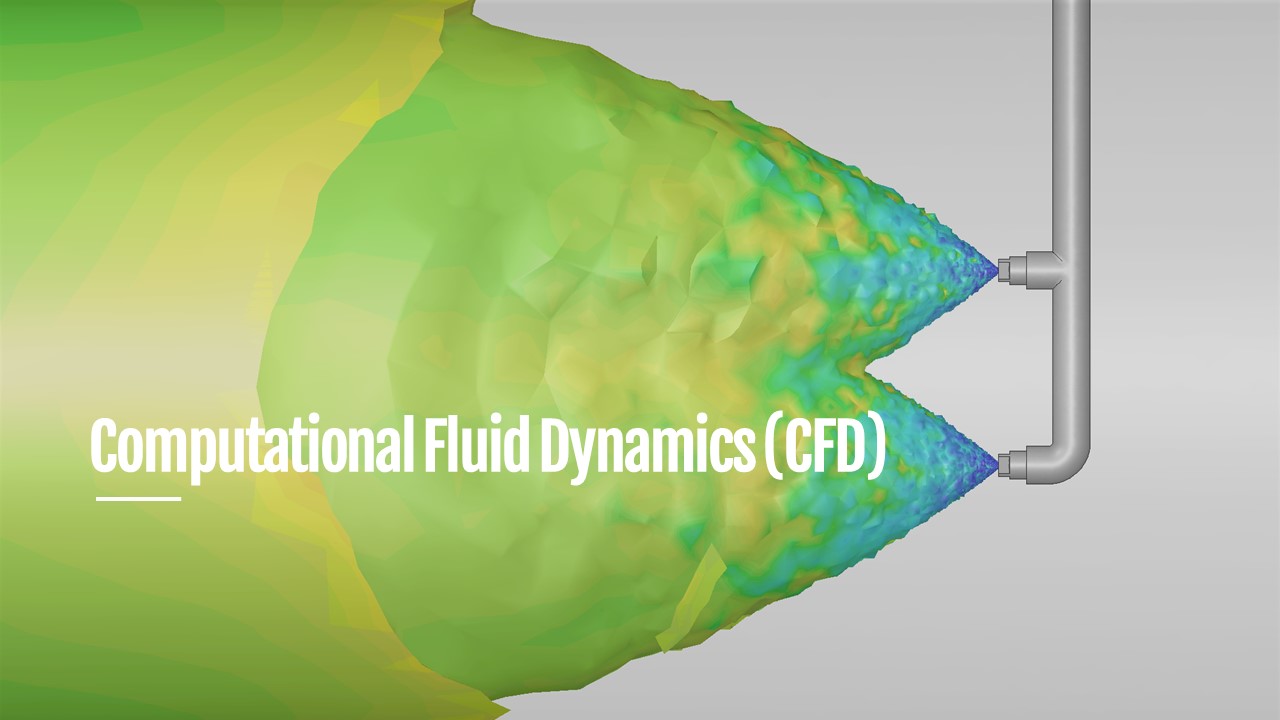

Lastly, I'll get into this. It is the CFD side of things. It's pretty important, we can use, computational fluid dynamics. I shared how each droplet matters, and how we can actually predict where these vapor streams and the droplets flow, how they move and what impact that might have on your reactors, or your heat exchangers for defouling or just particle tracking in general.

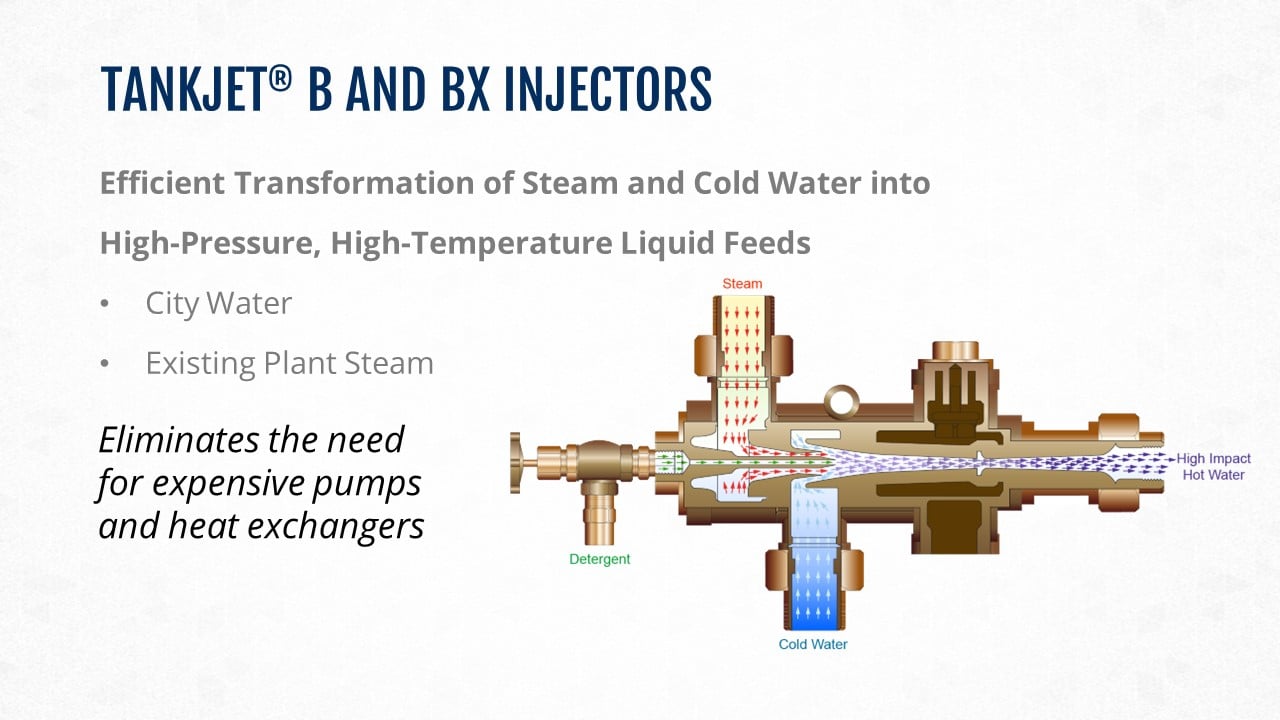

And then of course getting down to the steam injectors. We can we can go down that line as well from an optimization standpoint. We can talk more about that later if it's of interest, but the long and short of is you expend a lot of energy to heat your steam. And so if you want to heat to a certain temperature, you know, we can use a little bit of tech to help you guys out as well.

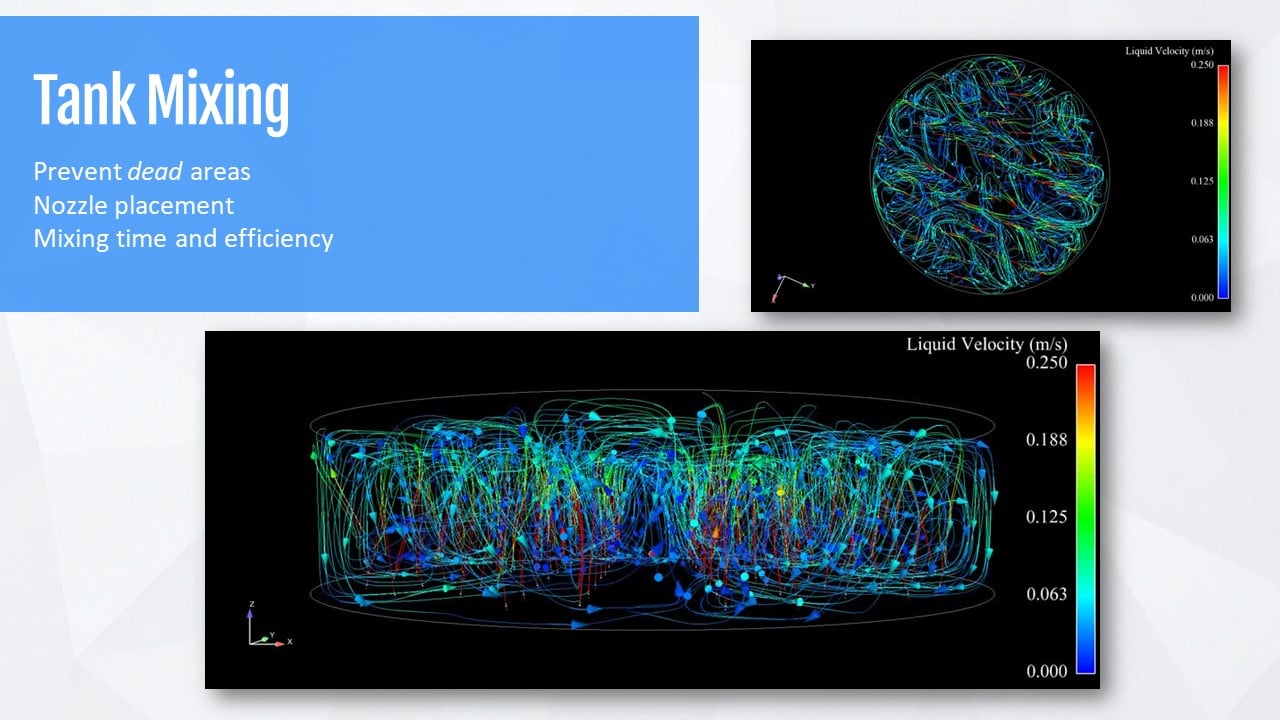

Another aspect you'll see and we do. The CFD for is the tank mixing, keeping a nice agitation movement. Yeah, that one. That one more. There we go. Technology.

Here I shared with you some of the technological tools that we're democratizing that are available. This is the embedded patternator. I do think that this might be of interest for some of y'all. Whether it's in your own lab to validate your spray patterns that you have or if you really want to get bold and put it in situ and see if you can get some live data feeds and see how that spread changes and get a little bit more of an understanding of what's happening. Like I said that's that little piece right there and how it looks and operates. Pretty relatively simple. Can you get a feedback heat map? Just like that.

So lastly, hey I did all right on time. So to recap we went through the why — why sprays, the DNA of the spray, we talked about some energy consumption examples, and shared with you a little bit of my wild experimentation in our Technology Center on the carbon capture side of things. We talked about CFD, tank cleaning, some of the innovation technology and that's all I got. All right, thank you so much.