Injectors, Lances and Quills

Injectors, Lances and Quills

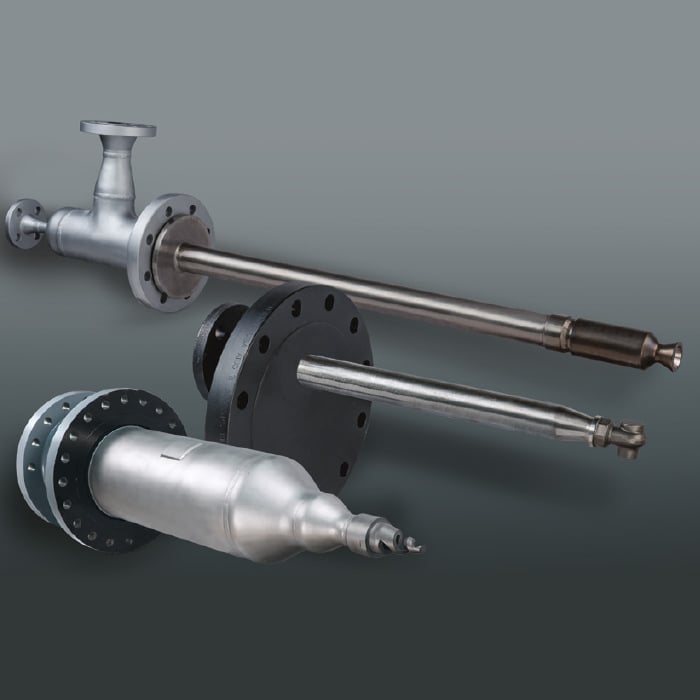

Optimize your spray performance with our standard or custom injectors, lances and quills. The devices that deliver fluid or gas to your spray nozzles can make all the difference on your bottom line.

Standard and Fully Customized Solutions

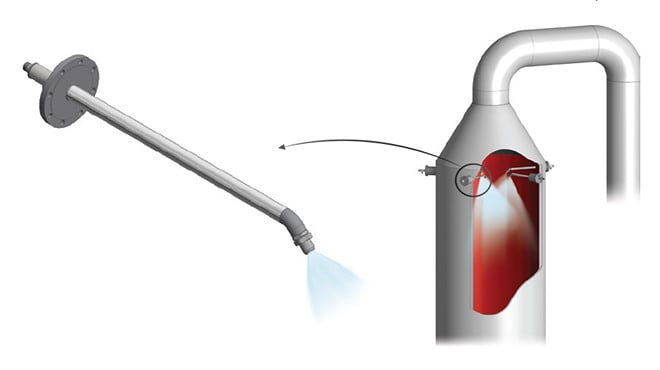

Whether you need a standard lance for tank cleaning or a built-to-order injector for a challenging environment, our experts can help. We’ll assist you in selecting the correct device for easy integration and optimal nozzle performance for tank cleaning, gas cooling and conditioning, desuperheating, quenching, wash water, chemical injection or NOx control. Our expertise can help you avoid a breakdown in these processes, which can cause damage to downstream equipment, wall wetting, refractory cracking, duct corrosion, premature furnace / tower failure, unscheduled outages and more. Depend on us to help you select a solution, or customize one for you.

- Standard gas cooling lances include 0°, 45° and 90° configurations with quick-release or bolt-on flanges with optional adapters, cooling jackets, purge tubes and protective tubes.

- Built-to-order tank cleaning lances optimize the performance of our TankJet® products. Choose from a wide variety of flanges and specify the pipe length, inlet connection and material of construction you need, and we’ll deliver with quick turnaround!

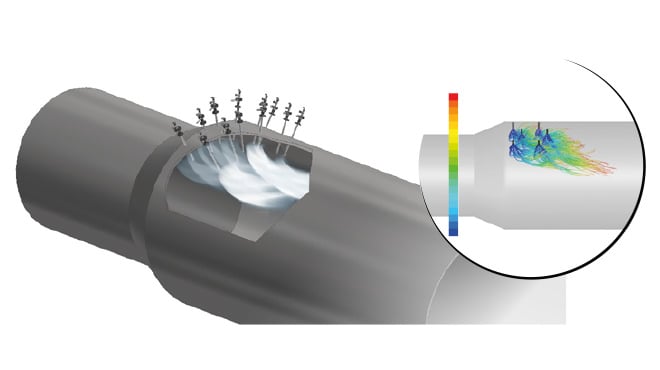

- Solutions for precision in refinery operations and other critical applications include assistance with nozzle selection and placement, injector placement and design requirements such as connection types, materials and maintenance features. We also often recommend validating performance using computational fluid dynamics (CFD) modeling and proprietary drop distribution studies to eliminate unforeseen problems.

With customers ranging from engineering firms to end users around the world, we have a proven track record of successful installations and ongoing support. Our global manufacturing and testing processes comply with global standards.