Sustainability Simplified

Helping You Make Waves

We understand the importance of our products to the industrial process, but we also understand the impact they have on our shared environment. This is why our spray technology experts spend every day helping companies around the world reduce their resource consumption, lower their carbon footprint and operate more sustainably. Not many companies can say this: our products are good for the world and the bottom line.

It All Starts with a Drop. . .

What goals are critical to your operations sustainability and ESG success? For most, the top three priorities include:

1. Reduce greenhouse gas (GHG) emissions

2. Decrease water use

3. Cut down on waste

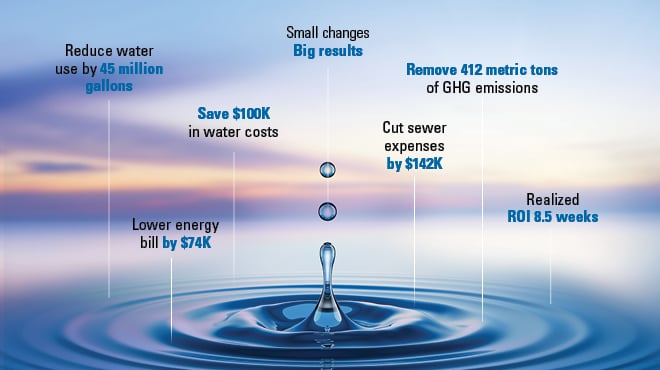

Although a top priority, decreasing water use is often overlooked as a primary catalyst in aiding companies progress in ALL three areas. That’s because there’s more to water use than meets the eye. In fact, simple changes can yield significant results for your operation thanks to the Ripple Effect – leading to an exponential return on investment (eROI) in months, if not weeks.

Understanding the Ripple Effect

By reducing the amount of water you use within your operation, you also reduce the amount of energy required to heat, treat and transport that water. This has a direct impact on lowering GHG emissions and minimizing your operations total carbon footprint.

But the good doesn’t stop there. Optimizing your operations spray processes can have a positive impact in a number of other areas, many of which are often overlooked:

Simplify and Apply

Making sustainable improvements can seem daunting, but it doesn’t have to be. Our Sustainability Assessment program was specifically designed to help you simplify and apply proven sustainability strategies across your operations. We do the work; you reap the rewards. That’s sustainability simplified.