Food Packer Saves Over US$130,000 a Year with Automated Spray System

Food Packer Saves Over US$130,000 a Year with Automated Spray System

Problem:

A cheese packaging company was using hydraulic spray nozzles to flood blocks of cheese on a conveyor with mold inhibitor. The coverage on the cheese was inconsistent and created quality problems. In addition, the nozzles sprayed continuously and coated the cheese and the areas between blocks. A significant amount of mold inhibitor was wasted and the overspray created maintenance and safety issues.

Solution:

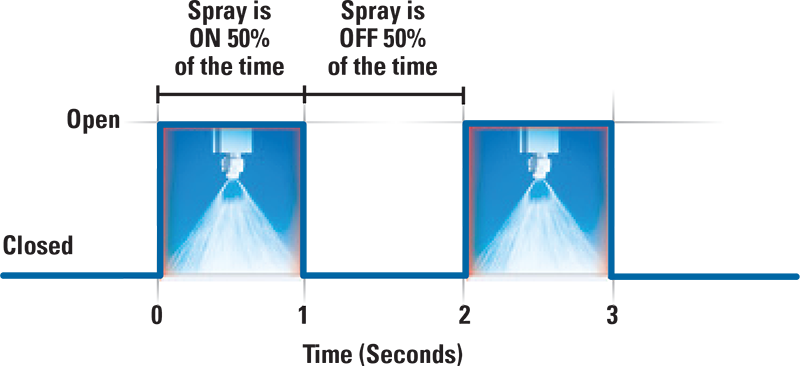

An AutoJet® automated spray system now applies the mold inhibitor on the cheese blocks. The system, equipped with four PulsaJet® electrically-actuated spray nozzles controlled by an AutoJet 1550+ Modular Spray System, dispenses the correct volume of mold inhibitor on each block of cheese with minimal waste. Using Precision Spray Control (PSC), the system makes automatic flow rate adjustments based on line speed to prevent over- and under- application of the mold inhibitor. The system also uses a photoelectric sensor to signal the nozzles to spray only when cheese is present.

Results:

The use of the AutoJet® automated spray system ensures the cheese blocks are uniformly coated with the precise volume of mold inhibitor required. The mold inhibitor is applied only when cheese is detected in the spray station. The elimination of overspray has resulted in a 60% reduction in mold inhibitor use, a 75% reduction in maintenance time and a safer work environment. The system cost was offset in less than two months and the company is saving more than US$130,000 per year.

For complete details of this case study click here to see the PDF version.