AutoJet® Spray Systems for Renderers & Pet Food Producers

AutoJet® Spray Systems for Renderers & Pet Food Producers

Improve product quality and reduce costs with precision application of antioxidants, palatants and other additives.

Precise Application of Additives

Automated AutoJet® spray systems ensure the proper volume of additive is applied uniformly and directly on the target, without waste and without compressed air. The result is better product quality, lower operating costs and increased production. No matter where your application points are and what additives are being used, we have a system to meet your needs.

Most processors apply a wide range of additives to offal and formed products at different stages of production to enhance product quality and extend shelf life. Most processors also struggle with challenges like:

- Over-application of additives, which is wasteful and costly

- Inconsistent application of additives, which results in quality issues, and production slowdowns

- Dangerous and messy misting that increases maintenance time and causes worker safety issues

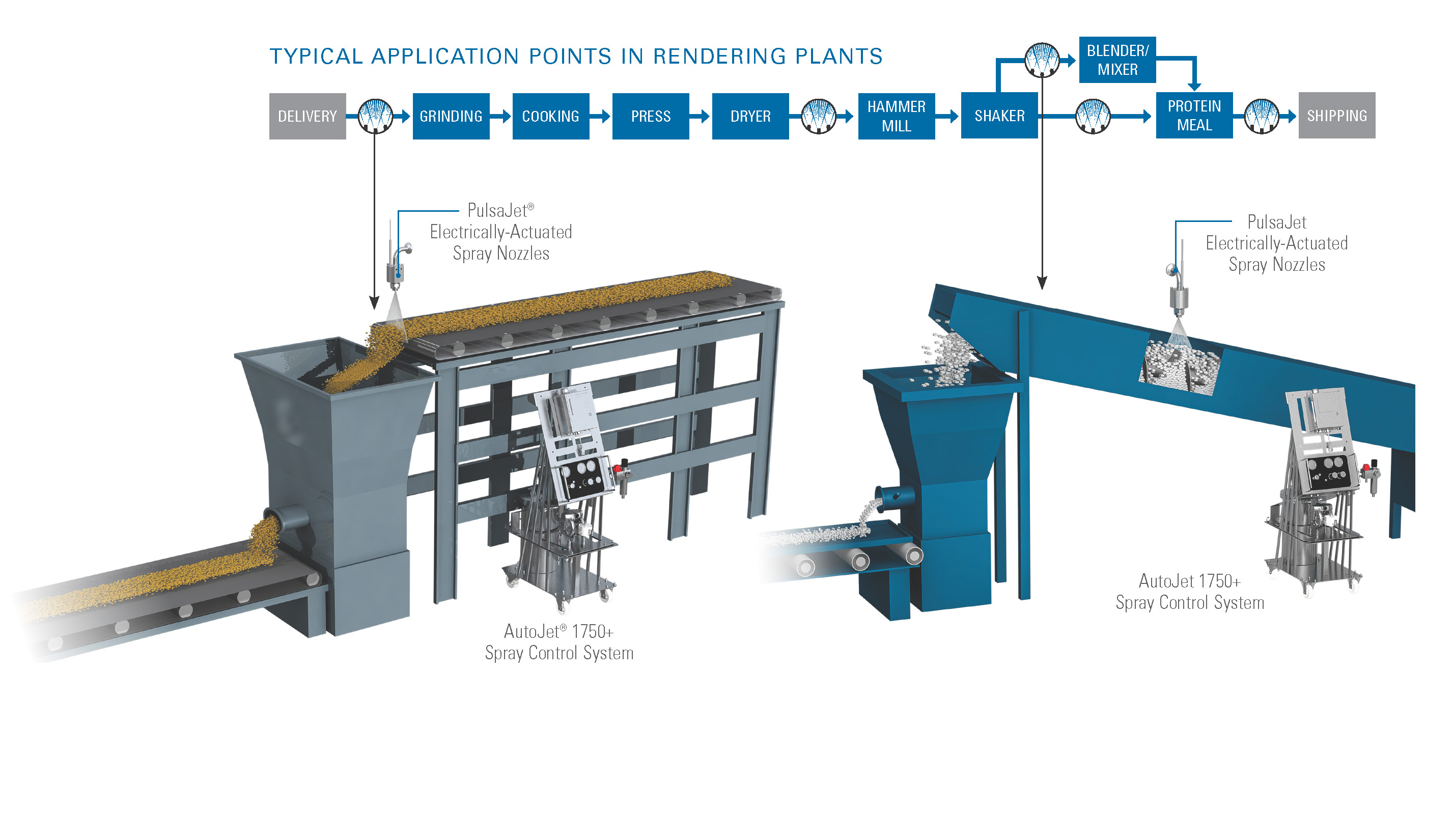

Rendering Plants

Ideally suited to apply antioxidants before the grinder, after the hammer mill, on the shaker table or in the blender, our AutoJet 1750+ Spray Control System with PulsaJet® hydraulic spray nozzles ensures consistent application to prevent oxidation. This system requires no compressed air and provides automatic adjustment of the application rate based on operating conditions such as changing line speed or the product weight in the tumbler/blender.

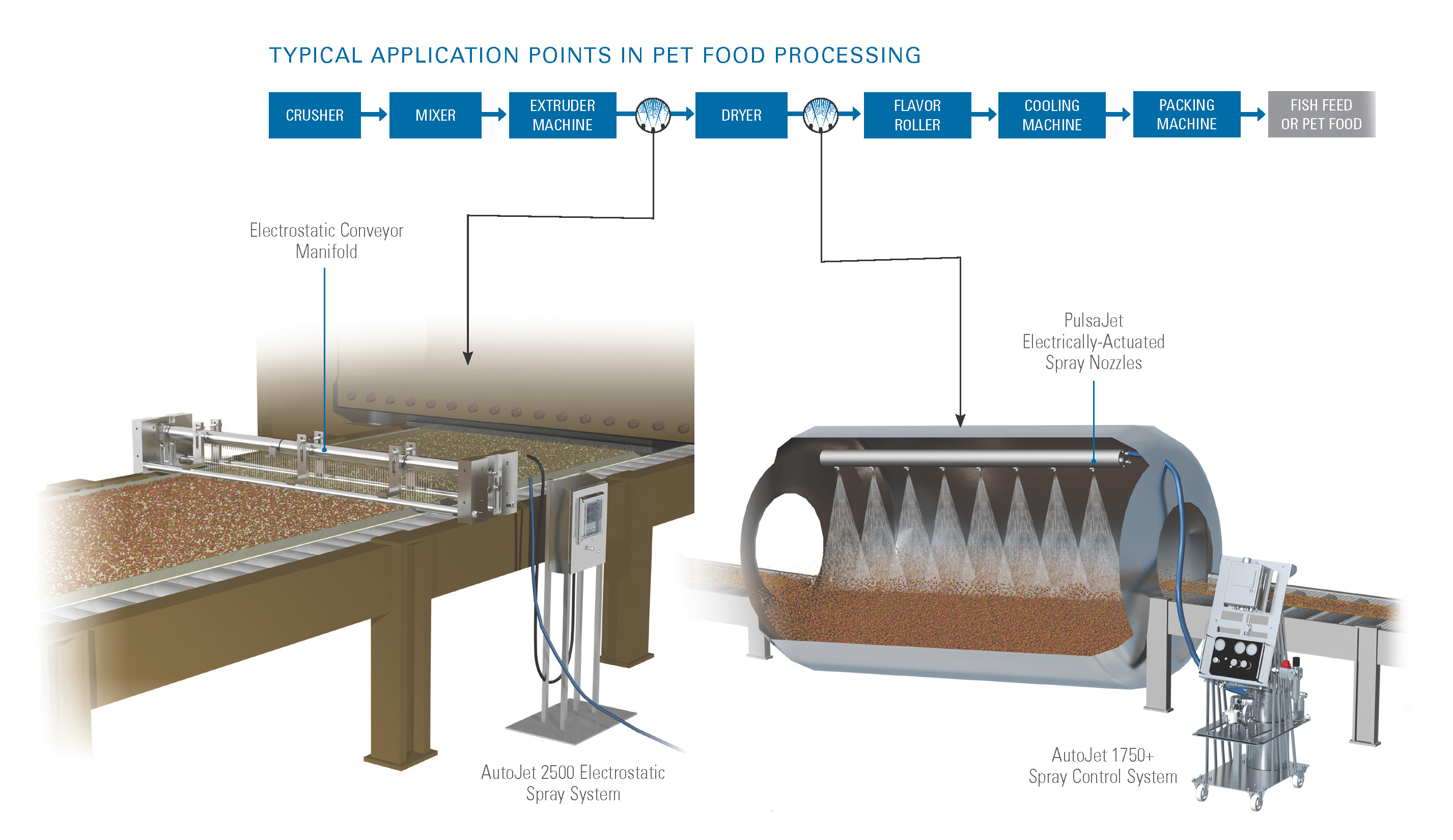

Dry Pet Food Processing

To prevent kibbles from sticking to dryer belts, release agents are often applied. Traditionally, systems with air atomizing nozzles have been used. The compressed air that atomizes the release agent results in messy, wasteful misting and high operating costs. We have two solutions that apply release agents and oil uniformly, with very little waste. The AutoJet 2500 Electrostatic System is ideal for low flow rates – 0.1-20 cc/min. For flow rates above 20 cc/min., the AutoJet 1750+ Spray Control System is recommended.

Another common operation involving spray technology is the application of oils, palatants, vitamins and other supplements in the tumbler/coater. The AutoJet 1750+ Spray Control System is widely used. The spray controller ensures additives are applied only when product is present, adjusts the application rate based on product weight in the tumbler/coater, alerts operators when tanks are low and stops production in the event of an application problem.

Related Products & Resources

Spray Technology Solutions for Renderers & Pet Food Producers

Precision additive application

AutoJet® 1750+ Spray Control System

Simple, flexible, precise spay control

AutoJet® ES2500 Electrostatic Spray System

Very fine, uniform spray at low flow rates

Precision Spray Control (PSC)

Precision Spray Control (PSC) enables accurate, consistent application of coatings, release agents, oils and more with minimal waste.