Coker

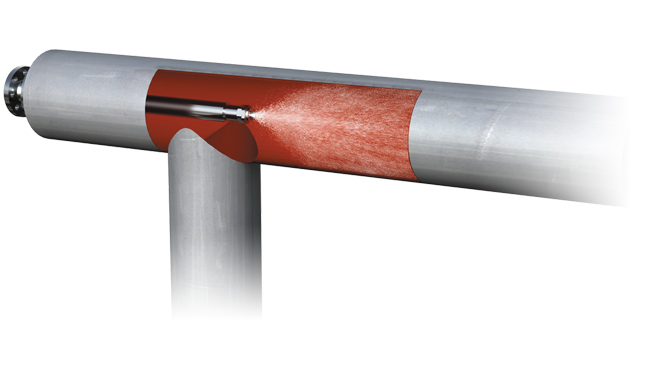

1. Quench Sprays

Problem: Slow down the cracking reaction while maintaining a thin liquid film on the walls of the overhead line to prevent coke formation.

Best practice: Inject coker gas oil into the coke drum outlet tee to quench and slow down the cracking reaction while maintaining a thin liquid film on the walls. Maximum Free Passage (MFP) FullJet® Full Cone spray nozzles reduce the chance to plug the spray nozzles, so they run longer. Wide spray angles are available and can be attached to a spray injector for easy installation.

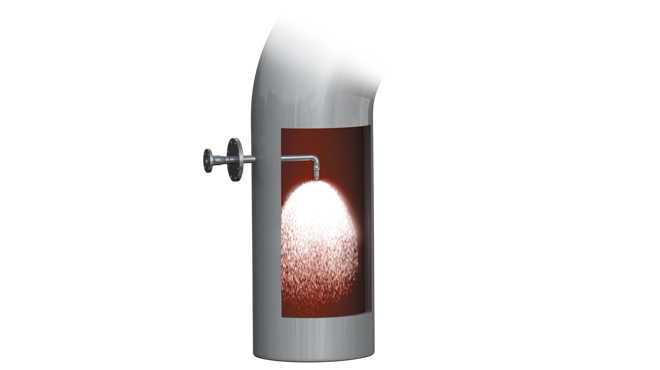

2. Defoaming

Problem: Keep foam from being carried over with the gas from the coke drum.

Best practice: Maximum Free Passage (MFP) FullJet® Full Cone spray nozzles reduce the chance to plug the spray nozzles, so nozzles run longer, as well as provide excellent coverage and larger droplet sizes at lower pressures.

3. Overhead Water Wash

Problem: Dissolve salt deposits that may have formed in the overhead vapor line.

Best practice: Wash water injection effectiveness is highly dependent on the size of the droplets and the location of the injection point into the process stream while maintaining at least 25% free water. Use advanced modeling tools such as Computational Fluid Dynamics (CFD) to model and analyze the operating conditions of the overhead vapor line. The modeling will determine the performance required of the spray injector, such as amount of water, droplet size and coverage for that particular process stream. Be sure to use precise droplet size information when creating models and running simulations to increase the validity of the results. Use CFD to validate performance before designing the injector. Using flow rate and pressure drop to determine injection points is not enough.

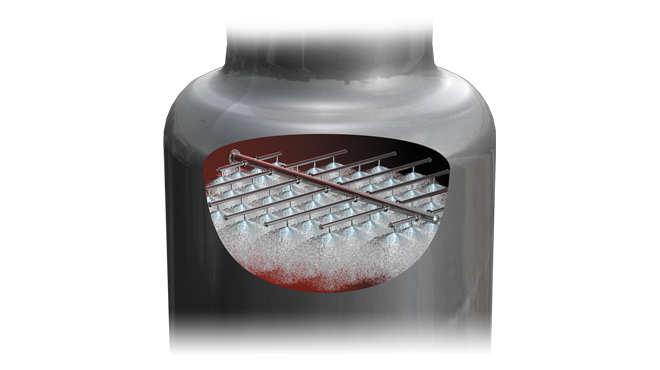

4. Wash Oil

Problem: Wash and cool the hot vapors that are entering the Fractionator from the coke drums.

Best practice: Maximum Free Passage (MFP) FullJet® Full Cone spray nozzles reduce the chance to plug the spray nozzles, so they run longer. Droplet size should be determined to ensure proper vapor to liquid interaction is optimized.