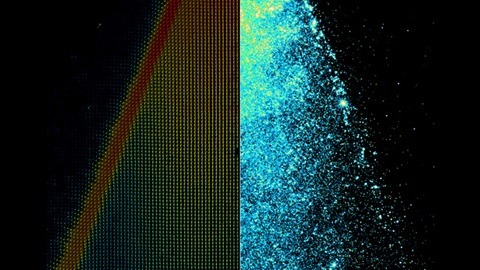

Particle Image Velocimetry (PIV)

Particle image velocimetry (PIV) provides planar measurements of particle or droplet velocities. A laser sheet is used to illuminate the particles within a plane, and two components of velocity (in the laser plane) can be determined by imaging the particle (or droplet) motion.

PIV Overview

The laser sheet is typically aligned so that one velocity component is in-line with the nozzle axis. Alternatively, the laser sheet can be aligned with a cross-section of the spray; however, this is only recommended with a very strong radial velocity component. Typically, many instantaneous velocity fields are determined and used to generate an ensemble average velocity field.

The simultaneous capture of 2D velocities across a spray-plane is a unique capability of this non-intrusive measurement method, and can be very useful in applications where the spray interacts with a target and for CFD validation purposes. Spraying Systems Co. uses a commercially available, but custom, LaVision Inc. PIV FlowMaster system, which also serves as the laser sheet imaging (LSI) instrument, as it utilizes a similar set of hardware.