Laser Imaging

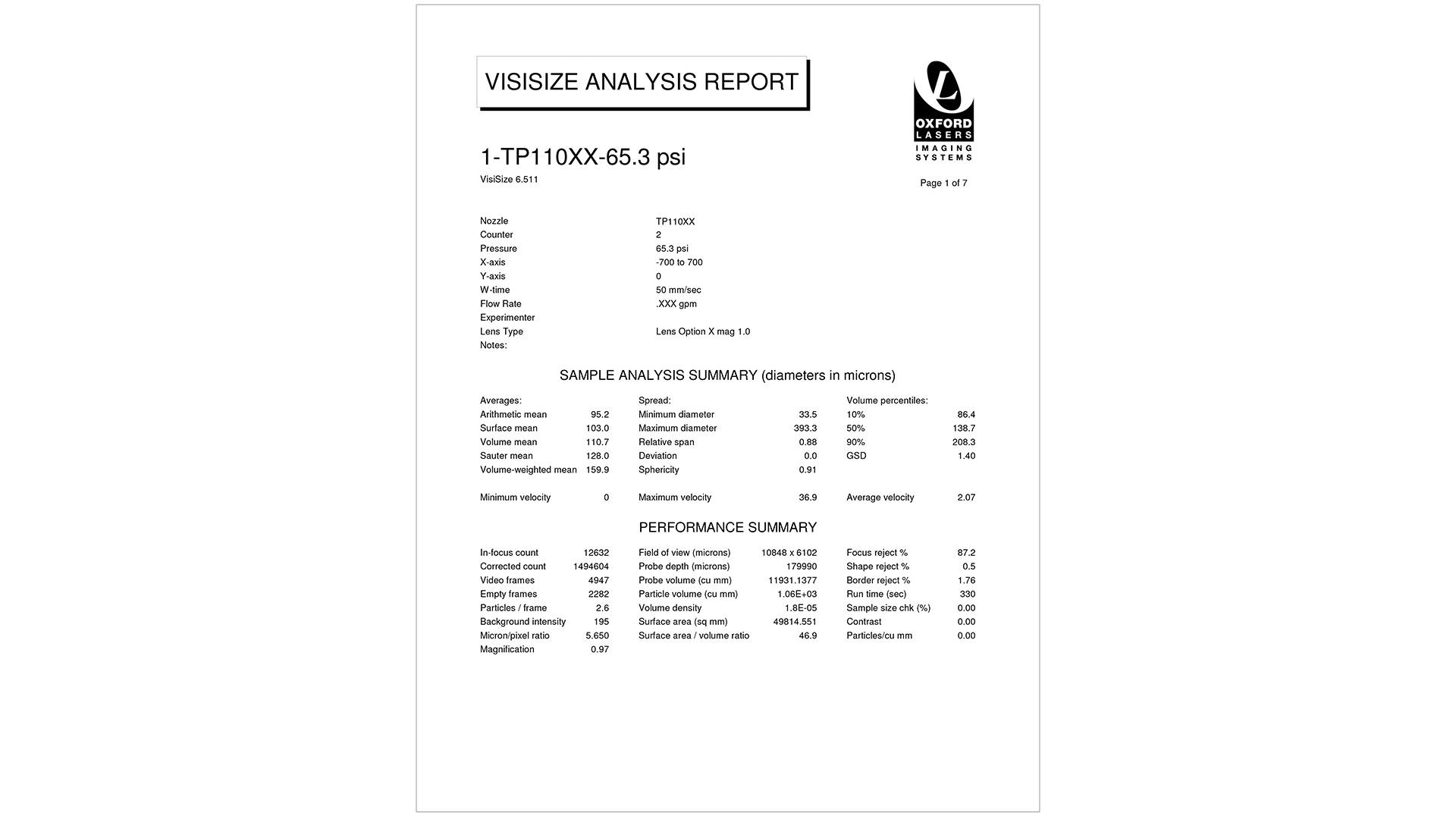

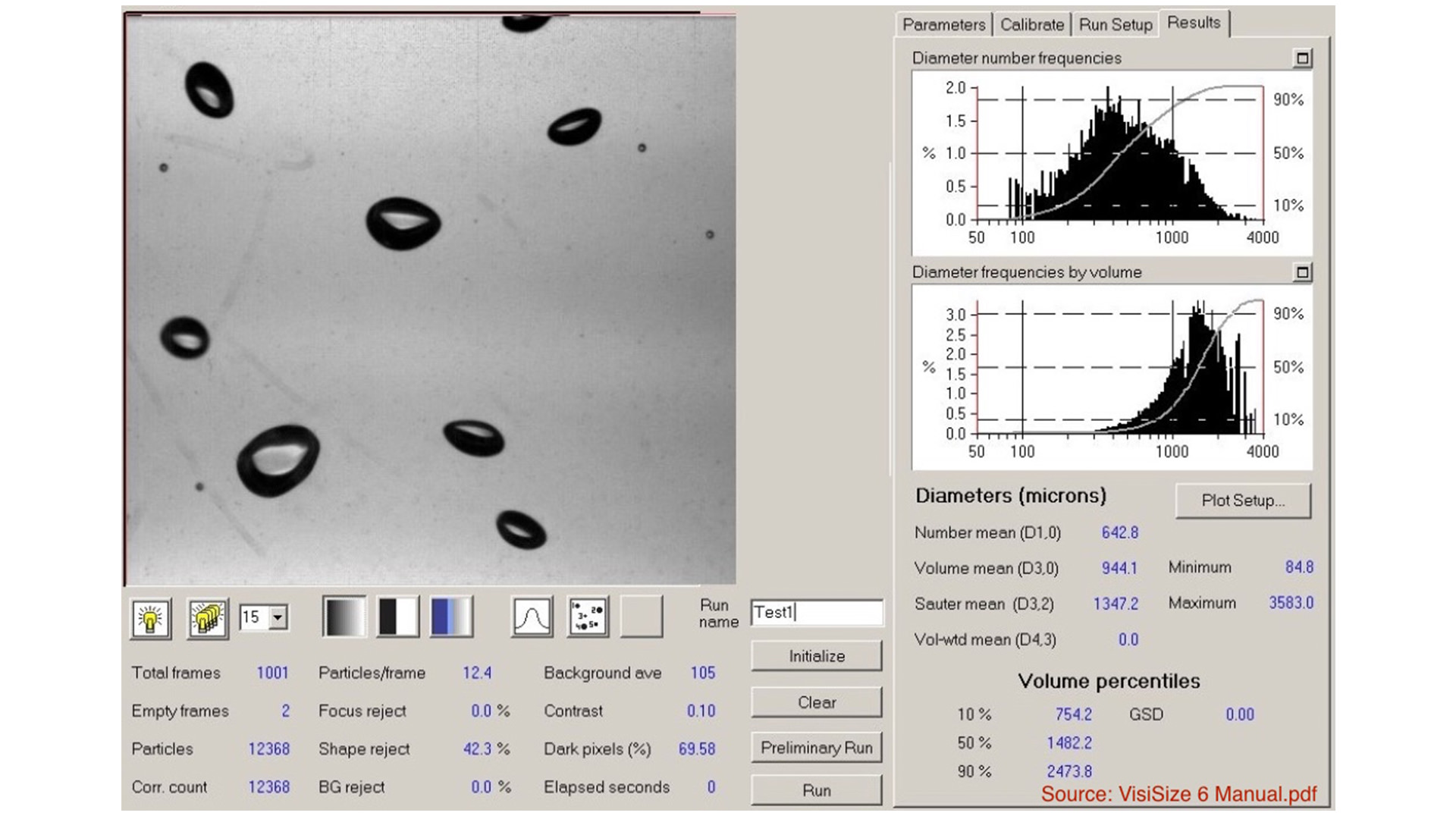

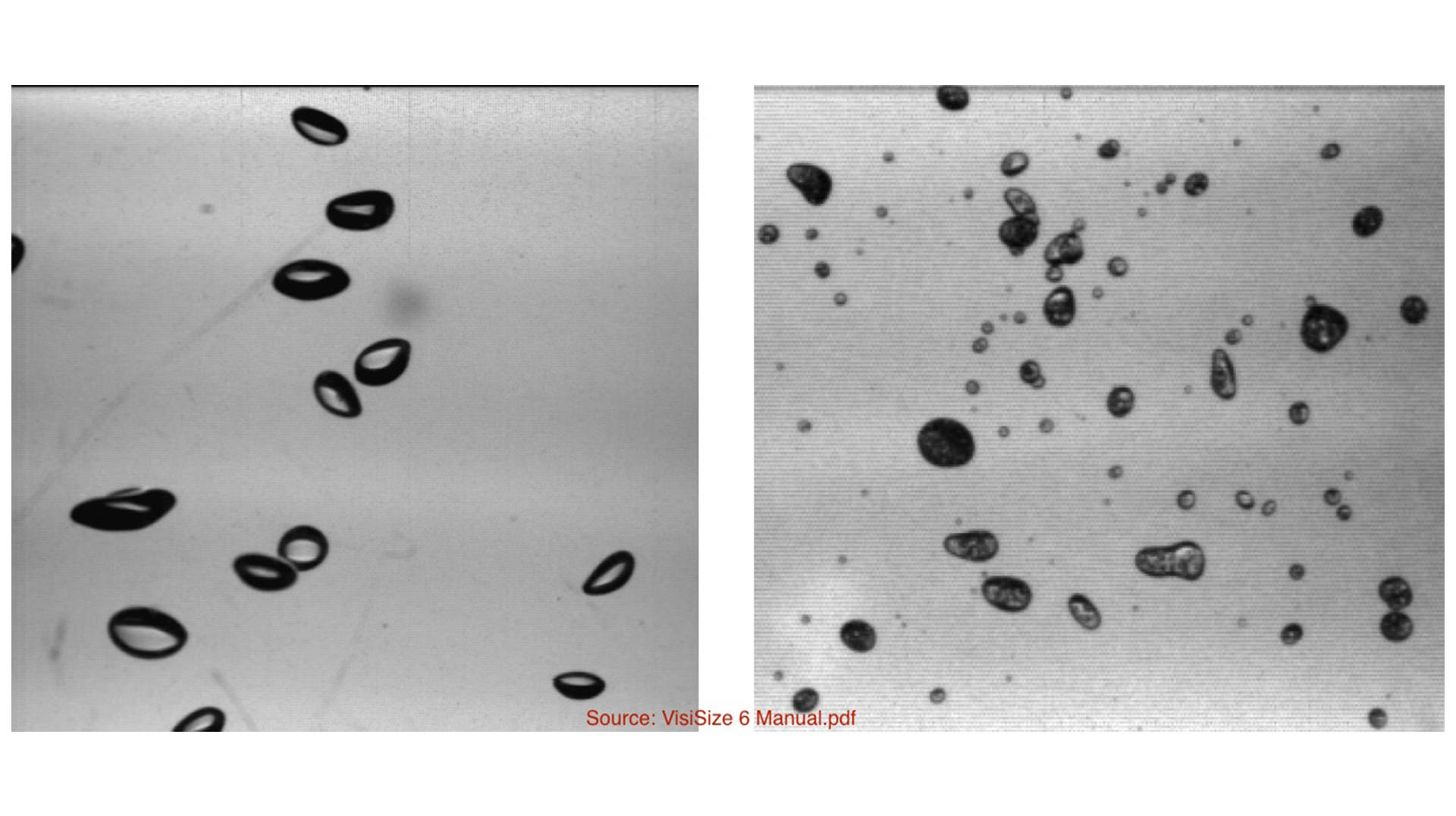

Laser imaging with the Oxford Imaging VisiSizer produces instantaneous images of a spray that allow for post-processing of droplet characteristics.

Laser Imaging Overview

The images are spatially calibrated and thus have an associated length scale reference with each image frame, allowing for measurement of the droplet / particle size. Furthermore, image pairs may be acquired in order to track droplet movement and determine velocity characteristics. Other characteristics may be determined from these images as well, including sphericity, solids content and concentration. Spraying Systems Co. uses the Oxford Imaging VisiSizer instrument.