AutoJet® Spray Control Enables Precision Eggshell Disinfection to Meet Customer’s New Standards

AutoJet® Spray Control Enables Precision Eggshell Disinfection to Meet Customer’s New Standards

Problem:

A large Canadian hatchery needed to implement a new practice for eggshell surface disinfection on the 1.5 million eggs it processes each week. The hatchery’s customer required the application of 0.8 ml to 0.9 ml of hydrogen peroxide to each egg in a way that covered the entire surface.

The hatchery first attempted to coat the eggs manually using handheld sprayers as they moved down a conveyor. They later tried spraying the eggs with a spray header comprised of standard hydraulic nozzles. Both methods resulted in overspray and misting, wasting hydrogen peroxide and endangering personnel in the area. Additionally, neither approach provided uniform or complete coverage of the eggs.

Solution:

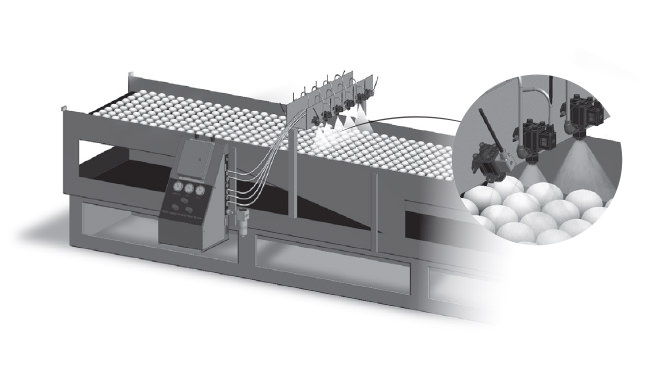

Spraying Systems Co. helped the hatchery solve the problem with 12 AA250AUH automatic nozzles and two AutoJet Modular Spray Systems. Each Model 1550+ Modular Spray System controls six nozzles mounted on a header spanning the conveyor. The conveyor moves the eggs in lines of 12. As each line of eggs approaches the header, a photoelectric sensor triggers a controlled spray of hydrogen peroxide from the first six nozzles. A second sensor triggers the second set of nozzles when the eggs have been rolled over, ensuring even and complete coverage. The nozzles spray only as eggs are passing underneath the header, so overspray, misting and material waste are practically eliminated.

Results:

The hatchery successfully implemented the new egg sanitizing system required by its customer, ensuring full coverage of the eggs. The AutoJet Modular Spray Systems apply the hydrogen peroxide more efficiently than the alternative systems, which were expected to require 30% more.

The system has also completely eliminated the possibility of eggs being rejected due to incomplete hydrogen peroxide coating. Considering the combined savings over alternative solutions, the payback period was less than nine months.

For complete details on this case study, click here to see the PDF version