A manufacturer of automobiles needed to apply a misting of RO/DI water onto the floor pans of passenger cars and trucks to prevent dust from kicking up during the painting process. Applying the water manually with handheld spray bottles resulted in inconsistent coverage, sometimes causing dust to reach the exterior of the auto body. This not only inhibited paint from adhering to the surface but required transport to a body shop for repair. The company required a spray solution that would use the same amount of water to consistently and evenly cover the floor pans and help reduce expensive rework.

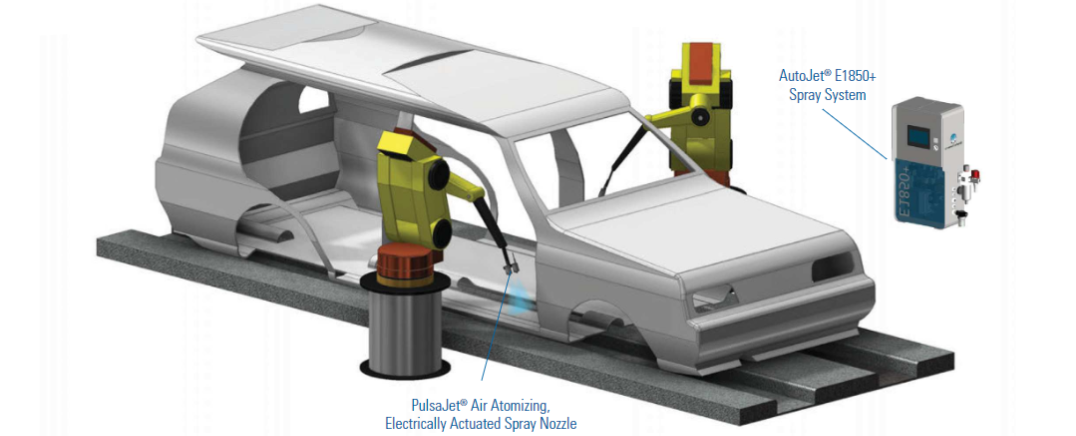

AutoJet Water misting system

We ran an on-site test with the AutoJet® E1850+ Spray System to demonstrate its liquid flow and drop size control. In partnership with a manufacturer of automotive painting equipment, four PulsaJet® AA10000JJAU air atomizing, electrically actuated spray nozzles were installed on robotic arms on either side of the production line. The arms entered the auto body through the windows to spray the floor pans. With a fine mist required to keep the floor dust at bay, Precision Spray Control (PSC) was used to generate low flow rates (4.9 to 7.6 liters/hour) and air and water velocities.

The AutoJet Water misting System was easily integrated into the OEM’s equipment. The collaboration provides complete, automated spray control of the nozzles and ensures precise placement of the water with minimal waste.

Result

Most importantly, the AutoJet E1850+ Spray System helped the auto manufacturer increase daily production rate. They also saw a reduction of 90% for dust-related and were able to reassign four employees to other tasks. Resource costs for paint, RO/DI water and compressed air consumption all were decreased significantly as well. As a result of the higher efficiency the costs for transporting and reworking rejected auto bodies dropped to a minimum.

The efficiency of the entire water misting system provided by the OEM, including the AutoJet system and PulsaJet spray nozzles, led to € 300,000 savings for the company, allowing it to achieve a payback period of less than a year.