A leading landscaping manufacturing company applies a waterproof coating on all the bricks they produce. In order for the acrylic coating to have the desired effect it needs to be applied to the top and face of all the bricks on a 1.5 m² board.

Until recently they were using a simple pump to push the acrylic coating through a single nozzle. This nozzle was constantly spraying as it was being moved over the board to spray all the bricks. The goal was to spray 1 gram per brick but the existing setup delivered inaccurate doses between 2.5 and 3.5 gram per brick.

As a result of this wasteful system the manufacturing process was overly expensive. The huge waste of expensive coating also created the necessity to clean the board in between applications. Clearly they needed a more sustainable solution.

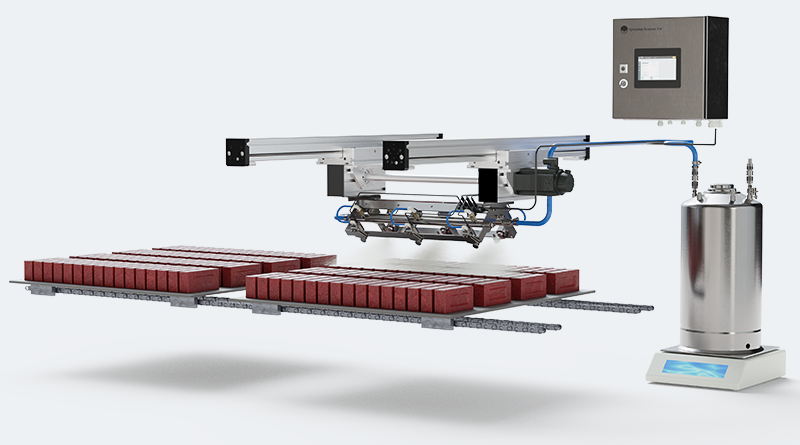

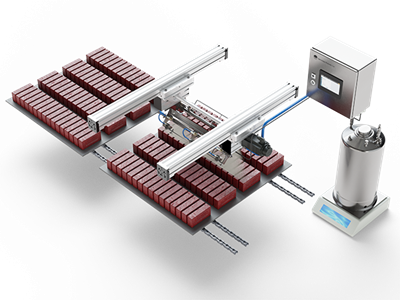

AutoJet® E2008+ Dual Channel Controller with PulsaJet® Nozzles

After extensive customer testing at one of the Spraying Systems Co.’s technology centers we decided on a solution that could satisfy the weight and speed requirements set forth.

After extensive customer testing at one of the Spraying Systems Co.’s technology centers we decided on a solution that could satisfy the weight and speed requirements set forth.

The solution uses an AutoJet® Spray System consisting of:

- • An AutoJet® 2008+ dual channel controller

- • 3 x PulsaJet® AAB10000AUH-03 nozzles per channel

- • Automatic agitating pressure vessel for supplying the acrylic coating to the nozzles

The automatic nozzles are mounted on a header with one channel facing the bricks and the other channel facing away. As the board is moving in we spray via the first channel to cover the top and side and the second channel is activated to spray the other side as the board is moving away.

With the new system the coating is applied more accurately and with a minimum amount of waste.

Result

Using the AutoJet® Spray System has had a big impact on the production process of this brick manufacturer. The application of the acrylic coating is being applied more accurately and with a minimum of waste. As a result of the more efficient process the clean down labor costs have dropped significantly. Perhaps even more important, because the system is no longer spraying continuously, our customer has experienced major savings in their acrylic coating costs.

Altogether the savings for the new sustainable coating solution amount to a payback period of 2 months.