A manufacturer needed a wood pellet oil spray system to spray oil on wood chips being pressed into pellets. The pellets, made from sawdust and wood chips, are mechanically formed into a consistent shape at high pressure. This results in a high-density heating fuel source. The oil acts as a binder for the pellets and also as a lubricant during the pressing operation.

A high pressure pump and a fine spray hydraulic nozzle were previously used. Unfortunately the viscosity of the oil being sprayed resulted in a poor spray pattern and uneven distribution of the oil across the wood chips. Over-application of the oil was a problem as well. The system was unable to adjust flow rate based on the tonnage of wood chips being processed.

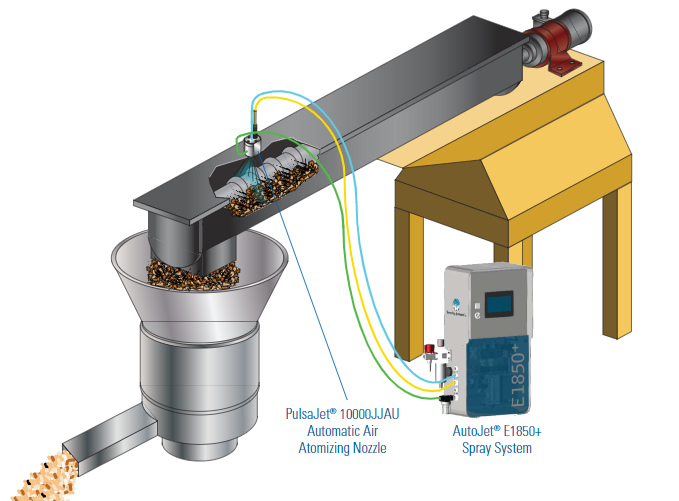

AutoJet wood pellet oil spray system

The Spraying Systems Co. solution consists of an AutoJet® E1850+ Spray System equipped with an air-operated diaphragm pump and a PulsaJet® 10000JJAU automatic air atomizing nozzle. The Spray System adjusts the electrically-actuated spray nozzle based on a 4-20mA input signal communicating the wood tonnage being processed. Controlling the flow automatically using Precision Spray Control (PSC) rather than by adjusting liquid pressure allows for instantaneous adjustment of the flow rate and maintains optimal drop size and spray angle, ensuring uniform coverage of the wood chips.

Result

Better control of the spray application using the AutoJet® Spray System has reduced the volume of oil used by 20%. More consistent lubrication of the wood chips has also resulted in fewer broken wood pellets and has greatly reduced the maintenance required on the press equipment. Together, these productivity improvements have saved the manufacturer more than € 10,000 annually. The payback period for the system was less than six months.