Climate protection is not only a local, but a global challenge, especially when it comes to air quality control. Around the world new technical solutions must be applied to accomplish compliance with environmental safety standards. In this mini-series we focus on two different cases of air quality control measures in combustion processes – dust suppression in Sebalang (Indonesia) and DeNOx in Pisa (Italy).

Reduction of nitrogen oxides using DeNox control

In glass production, the melting process is the main cause of nitrogen oxide emissions (NOx). Three main points of origin are (source pg 85-87):

- thermal NOx

- prompt NOx,

- the oxidation of released nitrogen from fuel or raw materials for glass production

A glassworks plant in Pisa has been equipped with a new SCR (Selective Catalytic Reduction) system in 2019 to reduce nitrogen oxide emissions (DeNOx). The goal was to reduce the NOx content in flue gas from approx. 1600 mg/Nm3 to < 300 mg/Nm3. For this purpose, ammonia water (NH4OH) is injected in front of a catalyst. At higher temperatures, the ammonia outgasses, and the water evaporates (source). The conversion of the nitrogen oxides then takes place with ammonia gas on the catalyst according to the following (simplified) reaction equations (source):

4 NO +4 NH3 +O2 → 4 N2 + 6 H2O

NO + NO2 + 2NH3 → 2N2 + 3H2O

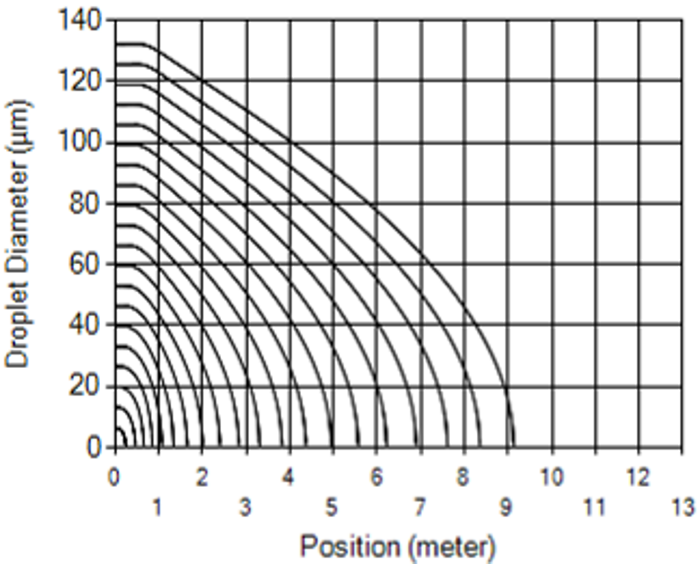

Under the assumption that NOx emissions consist mainly of nitrogen monoxide and that the reaction is at most effective at 90%, the required amount of NH4OH is calculated. The straight pipe length available for the reaction was 13 meters in Pisa. Using computer-aided simulation methods, the correct type of nozzle was determined, which guarantees a fine droplet spectrum and consequently a fast reaction of ammonia water and exhaust gas. Simultaneously, atomization air consumption should be low.

FloMax®: The right nozzle for the job

The figure above shows that with FloMax® FMX030 nozzles, a complete evaporation of the NH4OH can be achieved before the gas enters the SCR catalyst. Following the results of the computer simulation, two nozzle lances with FMX030 nozzles were installed in the flue gas duct, which spray in co-flow direction. Since mid-2019, these have been successfully used and help the plant operator to comply with the legal nitrogen oxide limits.

Thus, the emission values could be significantly improved using latest nozzle technology. If you’d like to learn more about DeNox control please contact us directly or download the brochure.