Layde Steel Manufacturing needs to spray anticorrosive oil on the sheet after the pickling process to avoid corrosion on the final product. To ensure the coating reaches the entire sheet Layde Steel was using an automatic pneumatic nozzle without a regulation system. This lack of control gave them no flexibility to adapt to the line speed; if the line was going fast they were underapplying and if it was going slow they were overapplying the oil. This resulted in various problems like quality issues, oil wastage, spillage on the floor, misting, clogging, …

Layde Steel were looking for an alternative solution that would give them full control over their lubrication process whilst maintaining a constant temperature of 50°C to prevent clogging.

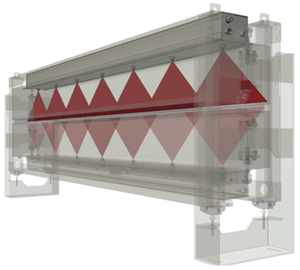

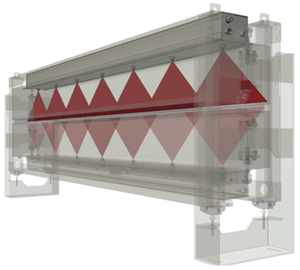

AutoJet heated lubrication system

After careful testing and evaluation, our local spray expert demonstrated a performant system that could meet the requirements. The AutoJet® HP170 Heated Lubrication System can easily maintain a constant temperature of 50°C. This ensures a smooth flow of the lubricant all year long. By connecting the system to 2 headers we can automatically adjust the spray based on the line speed. Each headers contains 7 PulsaJets® for optimal coverage.

To facilitate maintenance and prevent any possibility of clogging in the tubes the heated lubrication system is also equipped with a cleaning cycle.

Result

The installation of the AutoJet® HP170 system immediately provided the expected results. By accurately applying the correct amount of coating there are no more quality, misting and spillage issues. The system has helped Layde Steel to limit the use of the costly oil with over 60%, paying back the investment in less than a year. The results are happier workers, significant cost savings and a cleaner and safer work environment.