5 reasons why you should have been at PRC 2021

25

May 21

Last week we attended an online Petrochemical and Refining congress. During the 3-day event we had many interesting discussions with top-level delegates from the whole downstream value chain. Unfortunately, due to the pandemic, the congress was scaled down to a limited number of participants so many of you weren’t able to attend. Because of that we decided to list our 5 main focus points for PRC 2021.

1. FloMax® Hydrogen: Designed specifically for optimized wash water corrosion control in hydroprocessing units

A typical challenge in our industry is found in scrubbing chlorides from the effluent vapor.

Most installations use quills with no spray nozzles, or they use standard conventional spray nozzles. Neither of these are adequate for efficient scrubbing of the chlorides, because most of the water ends up on the walls of the pipes and enters the REAC in an asymmetrical distribution.

BEST PRACTICE:

The most efficient wash water injection will maximize the surface area of water injected, which will then maximize chloride scrubbing potential. This allows for not only better contact with the chlorides but also for more uniform distribution of the wash water through the piping system and REAC inlets.

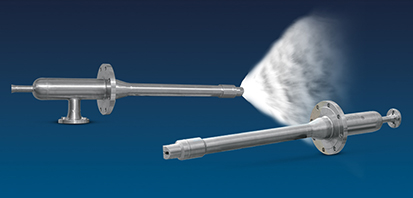

State of the art technology has been developed that uses a slipstream of makeup hydrogen as a secondary fluid in a two-fluid spray nozzle. The FM-H is a specially engineered and patented spray nozzle, which has been designed and tested specifically for use in hydroprocessing units

Find out more about the FloMax® H and watch the video.

2. FloMax® S01 Steam Atomizing Injector for neutralizer, H2S scavenger & chemical injection

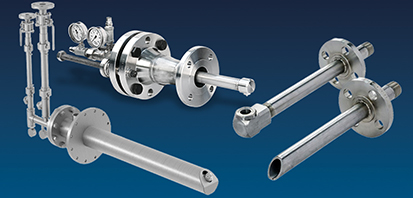

Our FloMax® S01 Steam Atomizing Retractable Injectors provide better performance than quills and single-fluid hydraulic nozzle injectors. In addition, the new injectors help reduce operating costs and minimize downtime.

FloMax® S Steam Atomizing Nozzle Benefits:

- • Patent-pending, multi-stage atomization process efficiently creates very small droplets and ensures volatilization and dispersion when the fluid exits the nozzles

- • Tight drop size control improves liquid distribution in process stream

- • Controlled atomization ensures consistent injection rates

- • Design of internal passages minimizes wear points and extends nozzle life

- • Wide range of materials available to match design requirements

FloMax® S01 Retractable Injector Benefits:

- • Minimizes manual labor and time required for injector installation and removal

- • Improves worker safety – injectors can be retracted easily from a catwalk

Find out more about the FloMax® S01 and watch the video.

3. OptiMax Injector: Advanced technology for superior mixing and superior atomization

Looking for a better solution for torch oil, slurry backflush, quench, and other similar injection operations?

The OptiMax injector from Spraying Systems Co. is specially designed to produce a uniform spray pattern for quick vaporization. The injector mixes steam with the oil, hydrocarbons or chemicals using a unique, patented atomization process. This process ensures thorough mixing of the steam and fluid prior to injection. The mixed fluid that exits the injector consists of small drops in a uniform spray pattern.

BENEFITS:

- • Thoroughly mixed fluid and uniform spray coverage optimize the effectiveness of the chemical reaction

- • Fast vaporization of the hydrocarbon for quicker reaction in the process stream

- • Better control of drop size over a wide flow rate range provides more operating flexibility

- • Durable, dependable design for long wear life

- • Uses available plant steam instead of costly compressed air – better for the environment and the bottom line

Find out more about the OptiMax and watch the video.

4. Spray Injectors & Quills: A large selection of fixed and retractable spray injectors, lances and quills

All our technology is at your disposal with one goal in mind: Optimizing your processes to meet your efficiency and sustainability targets, in any of these petrochemical processes:

• Defoaming • Steam quench • Torch oil

• Wash water • Slurry backflush • Regenerator bypass

• Feed injection • Glycol / Chemical Injection • Gas cooling or quenching

• Tank mixing and blending • De-Superheating SNCR and SCR NOx Control

If your operation requires the addition of a liquid or gas to a process stream, we are uniquely qualified to supply the delivery equipment. Commonly referred to as lances, quills, spray injectors and guns, this equipment is instrumental in achieving the desired cooling, mixing, quenching, washing, humidifying, gas conditioning and/or chemical reaction. A breakdown in any of these processes can potentially damage downstream equipment, wall wetting, refractory cracking, duct corrosion, premature furnace/tower failure and unscheduled outages.

5. Spray Analysis & Research Services ensures optimized spray nozzle selection and placement

Our team can help you to discover new ways to apply fluids, cool gasses and nozzle placement and orientation may be optimized. Our dedicated spray lab is equipped with the latest advanced testing equipment and modeling services:

- • Spray droplet characterization

- • Fluid Mechanics

- • Spray Diagnostics

- • Prototyping

- • Computational Fluid Dynamics (CFD)

- • Fluid Structure Interaction (FSI)

All this technology is at your disposal with one goal in mind: Optimizing your processes to meet your efficiency and sustainability targets in any petrochemical processes.

Our CFD modeling of sprays uses actual drop size and velocity data we’ve collected in our labs. We use this extensive database of performance data in every model where drop size and velocity play a role in the physical process.

Our experienced engineers, specialists in spray technology, understand when to rely on our proprietary data or conduct additional testing in the lab to ensure the required level of accuracy.