AutoJet® Robotic Spray System

AutoJet® Robotic Spray System

The AutoJet® Robotic Spray System offers unmatched versatility, efficiency and operating flexibility for complex coating and drying operationsAdvanced Spray Technology Solutions to Maximize Operational Efficiency and Reduce Waste

The marriage of precision spray nozzle technology and robotics offers manufacturers a new way to coat and dry unusually shaped parts and/or parts of varying sizes. Integration of a robotic arm and vision system with precision spraying results in dramatic increases in throughput and reduced consumption of costly fluids.

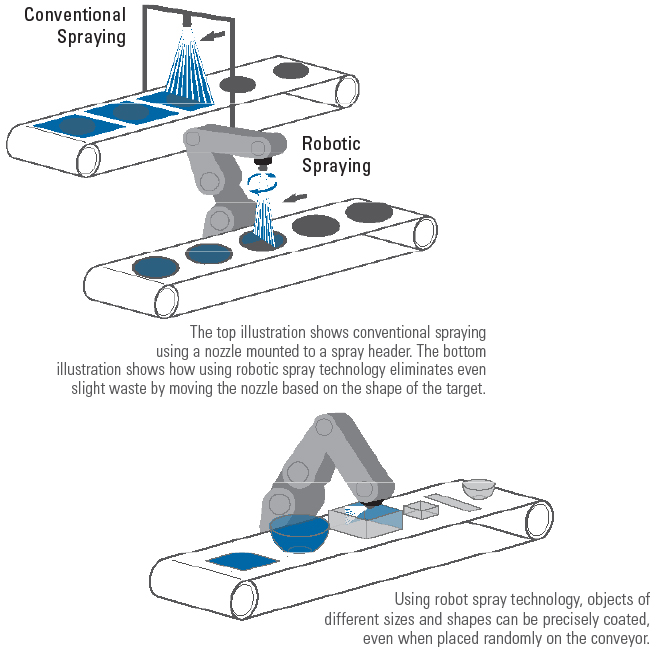

In many conveyorized operations, spray nozzles are mounted above, below and/or on the side of the conveyor, coating products as they pass through the spray station. Uniform coverage of products can be achieved without any overspray in many operations. However, depending on the shape of the product and the spray pattern of the nozzle, some overspray may occur.

Spray nozzles mounted on headers are ideal for applying fluids to products of the same size and shape that are placed in a predetermined position. When product size or placement varies, fluid waste increases, coating accuracy decreases dramatically and QC problems escalate, creating scrap and/or rework.

The integration of a robotic arm and vision system with spray nozzle technology provides a high degree of accuracy and the elimination of coating waste. Instead of being in a fixed position, the nozzle is in motion and applies the coating based on the shape and placement of the product. The system automatically adjusts the volume of fluid dispensed, spray height, nozzle position and motion path to ensure precision coating.

AutoJet® Robotic Spray System Benefits

- Reduced consumption of fluids and coatings through precise application. Only the product is coated, eliminating overspray

- Uniform coverage of unusually shaped parts. The proper volume of fluid is consistently applied – even in hard to reach interior areas. Consistent application reduces rejects, rework and scrap

- Increased operating flexibility and cost savings. Eliminates the need for fixed product placement on conveyors and single product runs. Operators can mix and match products, which eliminates costly tooling for product orientation and downtime to change out spray setups

- Reduced labor costs. System enables higher level of automation. In many operations, human intervention can be eliminated