Answer Guide

Answer Guide

Discover new ways to operate more sustainably and see how much you can save. It’s all prepared for you in a customized report with the facts, figures and outcomes clearly documented.

WHAT IT IS

Sustainability is only the start.

The Sustainability Assessment Program from Spraying Systems Co. is a proven process that will help your operations become more efficient, productive, sustainable and safe.

It happens on-site, at any plant you choose, with no disruptions to production. And the results can be significant — all from some very small changes.

During the assessment, our team of spray technology experts will visit your plant to evaluate essential spraying applications such as cooling, coating, cleaning, drying, mixing and others.

Our experts will identify actionable ways to:

-

Reduce water, chemical and energy use

-

Reduce scrap and waste

-

Improve worker safety

A few weeks after the assessment, Spraying Systems Co. will share the findings. You’ll discover new ways to operate more sustainably and see how much you can save. It’s all prepared for you in a customized report with the facts, figures and outcomes clearly documented.

WHY IT MATTERS

The Sustainability Assessment Program matters because it reveals some surprisingly simple changes you can implement immediately to save water, energy, chemicals and money. You’ll recoup the cost of these changes in just a few months, if not weeks.

If that seems too good to be true, consider the facts below.

SIMPLE CHANGES EXAMPLE #1

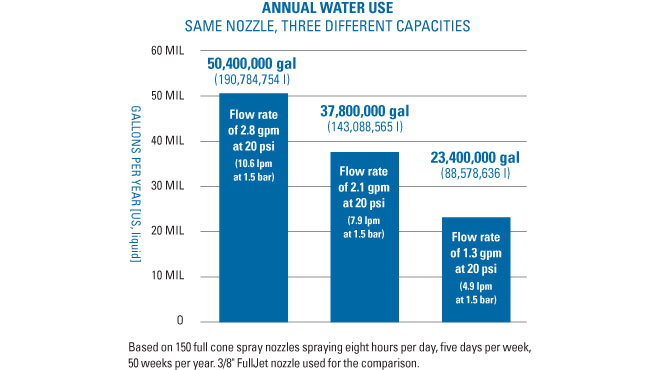

Reduce Flow Rate

In some operations, lowering the flow rate won't negatively impact performance and the savings can be significant.

SIMPLE CHANGES EXAMPLE #2

Optimize and Automate Cleaning of Tanks and Other Equipment

- Water savings typically range from 50% to 75% when tank cleaning nozzles replace manual cleaning

- The risks associated with tank entry and exposure to toxic fumes are eliminated and in-demand workers can be deployed to other tasks

- Cleaning time can be reduced by as much as 90% and tanks/equipment can be returned to service more quickly

- If tank cleaning nozzles are currently in use, newer technology can help reduce water use further

2. PRE-ASSESSMENT

GOALS: Establish an action plan

WHAT HAPPENS:

-

During a video call, we’ll review your priorities and develop the action plan

-

You complete some worksheets to help ensure the most productive assessment

3. ON-SITE ASSESSMENT

GOALS: Evaluate plant operations focusing on the applications agreed upon during the pre-assessment

WHAT HAPPENS:

-

Our team visits the plant of your choice on a date and time that works best for you

-

The spray technology experts evaluate cooling, coating, cleaning, drying, mixing or other operations based upon the items you prioritized during pre-assessment planning

4. POST ASSESSMENT

GOALS: Report findings and actionable recommendations

WHAT HAPPENS:

-

Spraying Systems Co. will analyze all the data and calculate potential savings

-

We’ll provide recommendations to achieve those savings and project the ROI on any equipment needed

-

All findings will be documented in a customized report with clear, actionable steps

5. FOLLOW UP

GOALS: Determine next steps

WHAT HAPPENS:

-

A few weeks after the report is presented, we will follow up to discuss implementation

WHO IT BENEFITS

The Sustainability Assessment Program from Spraying Systems Co. benefits everyone.

- Your company saves substantial amounts of water, energy, chemicals and money

- Your employees have a safer work environment

- Your shareholders learn about the positive, sustainable actions your company is taking

- Your community sees you as a good corporate citizen

- Our planet has more vital resources because you’re making every drop count

WHEN TO GET STARTED

The short answer is right away. That’s because the sooner you schedule a Sustainability Assessment, the faster you’ll realize the savings.

The customized report you receive after the assessment includes detailed recommendations. This is your roadmap to increase sustainability and savings by decreasing water and energy use on every shift. You’ll also get ROI projections and a clear implementation plan.

In addition, Spraying Systems Co. does most of the work. After you provide some basic information about your operations, we’ll conduct the on-site assessment without disrupting production.

We’re ready to help you save ASAP. So let’s get started.