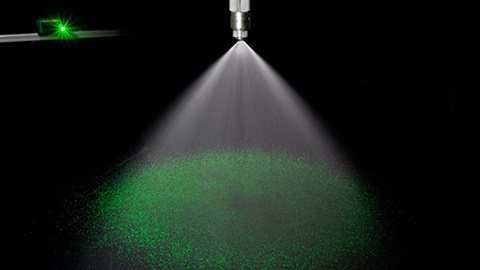

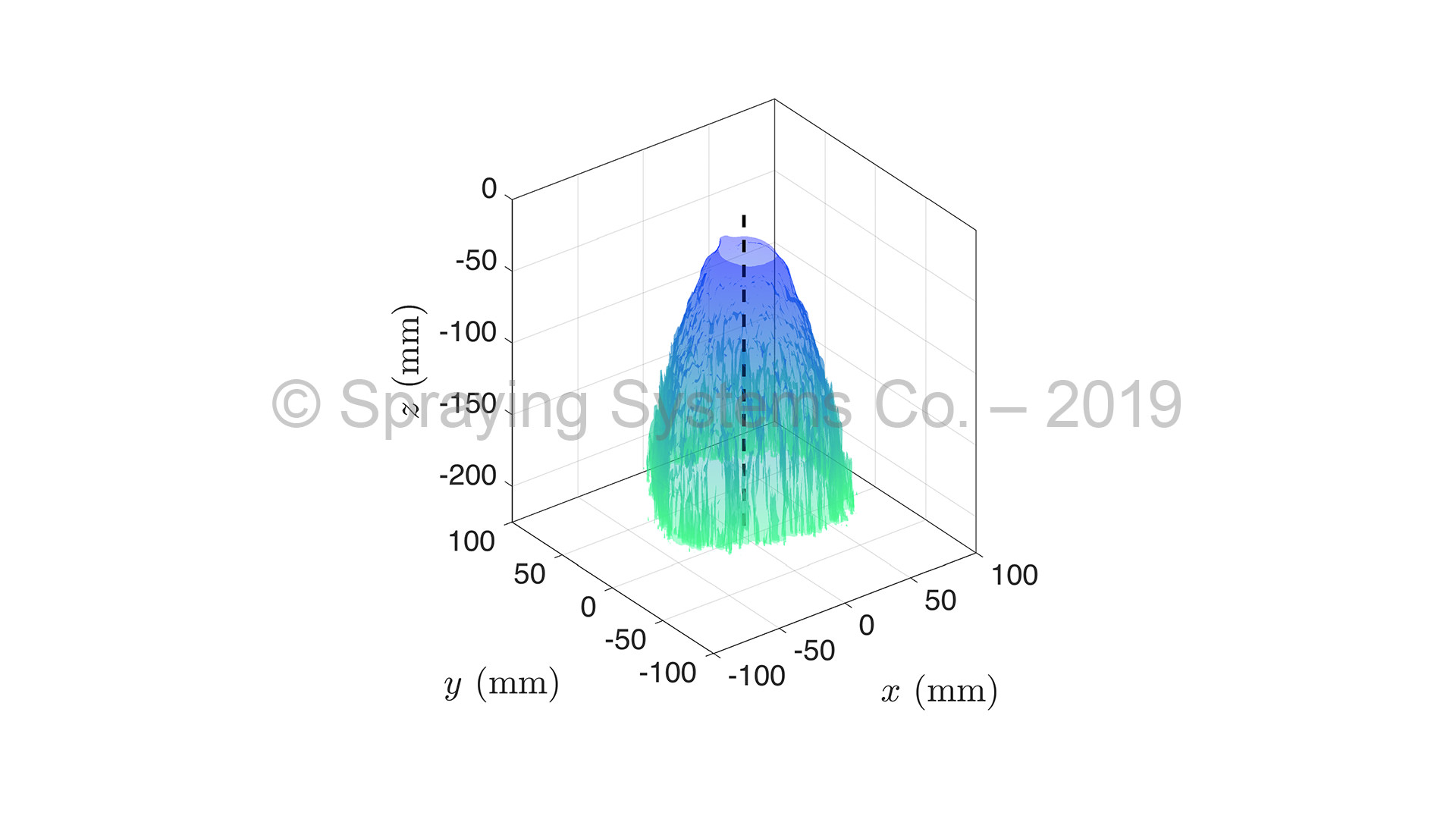

LSI uses a short-duration pulsed laser, which is passed through a divergent lens, to illuminate a planar cross-section of the spray pattern. The short laser pulse effectively freezes the spray droplets in place as they are imaged. The droplets scatter the laser light and a camera, which is triggered with the laser pulse, images the droplets within the laser plane. A band-pass light filter is attached to the camera lens, which allows only light of the wavelength of the laser to pass to the CCD sensor, essentially removing all out-of-plane droplets from view.

-

The Mie Theory

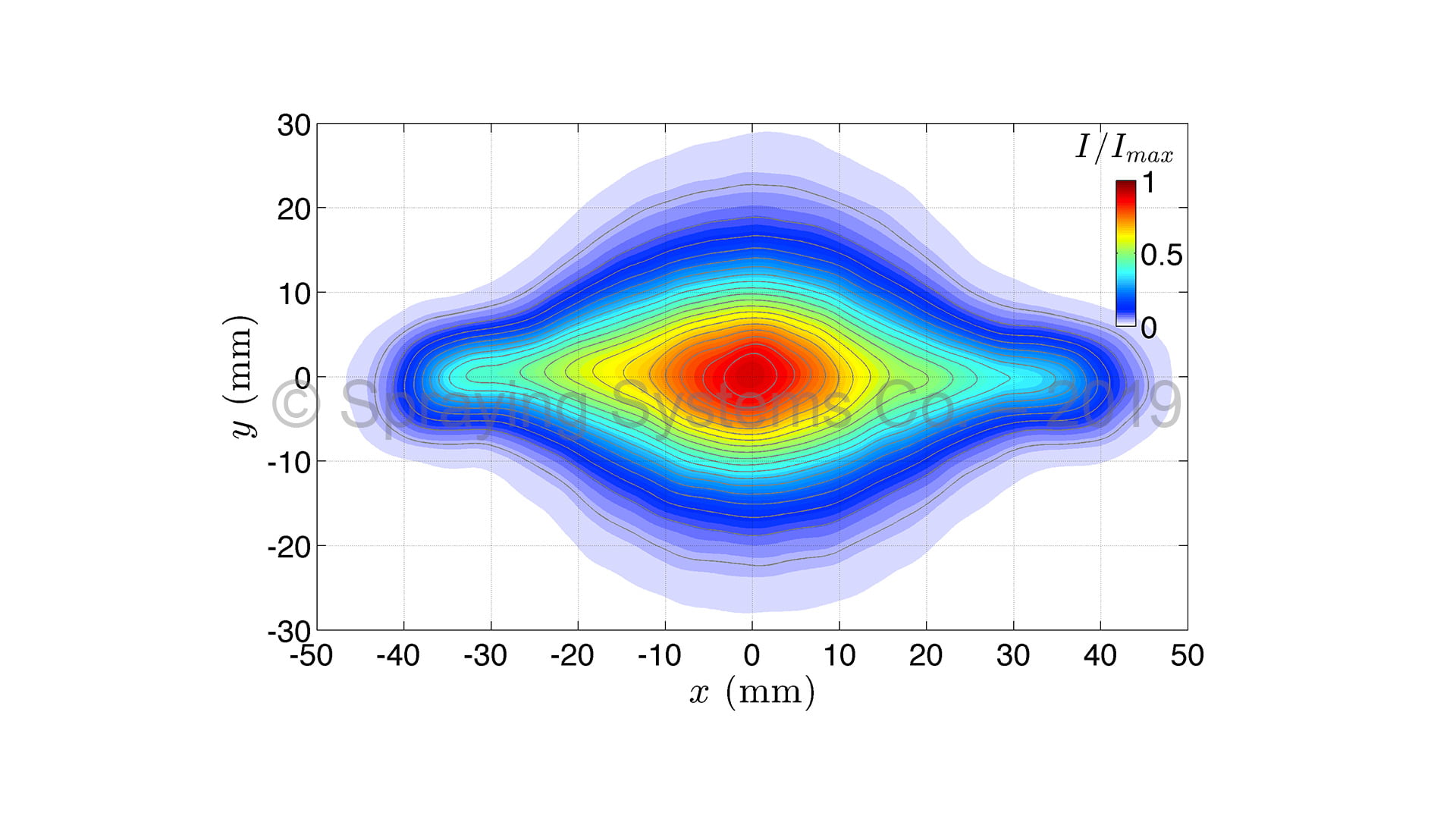

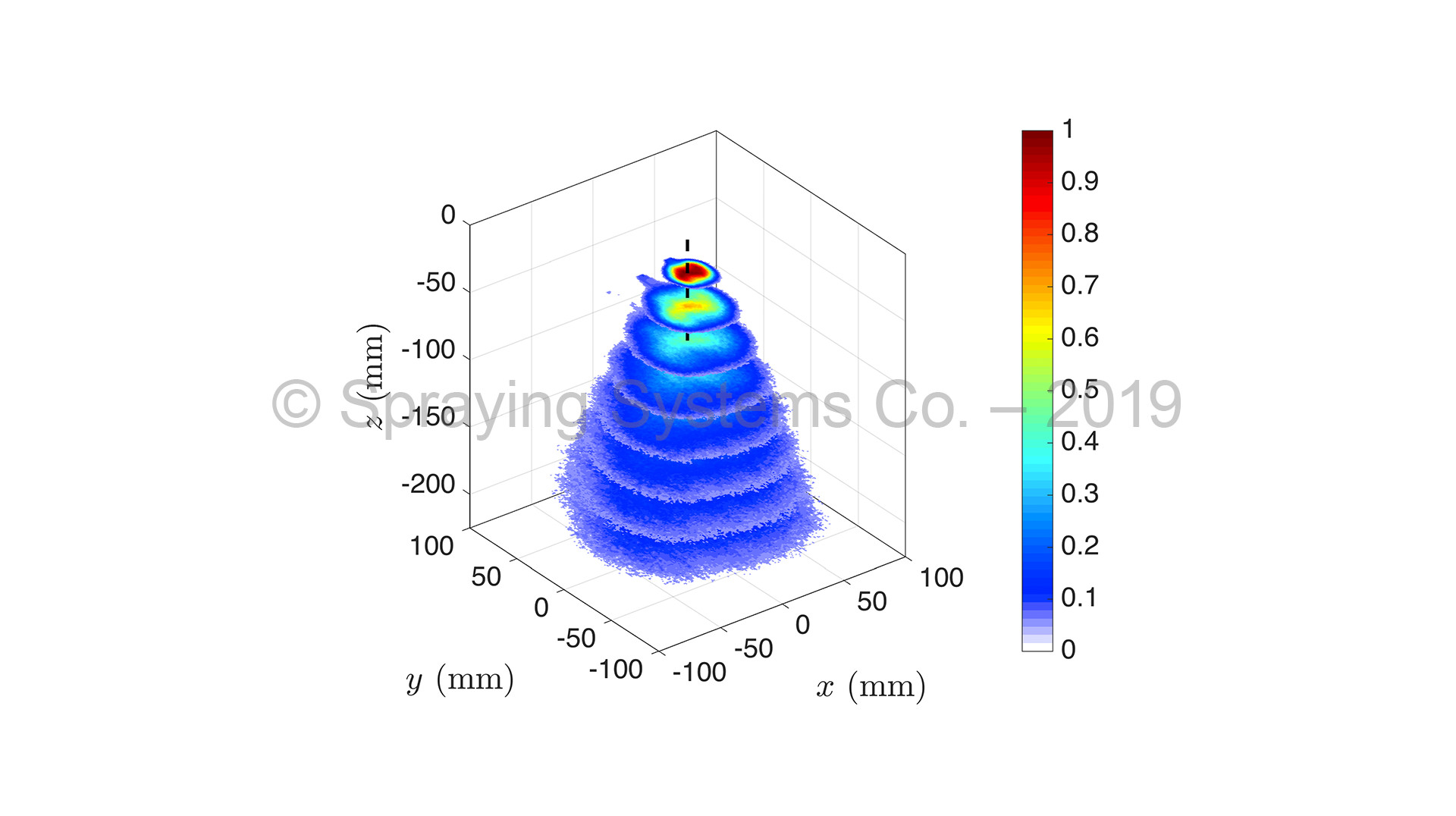

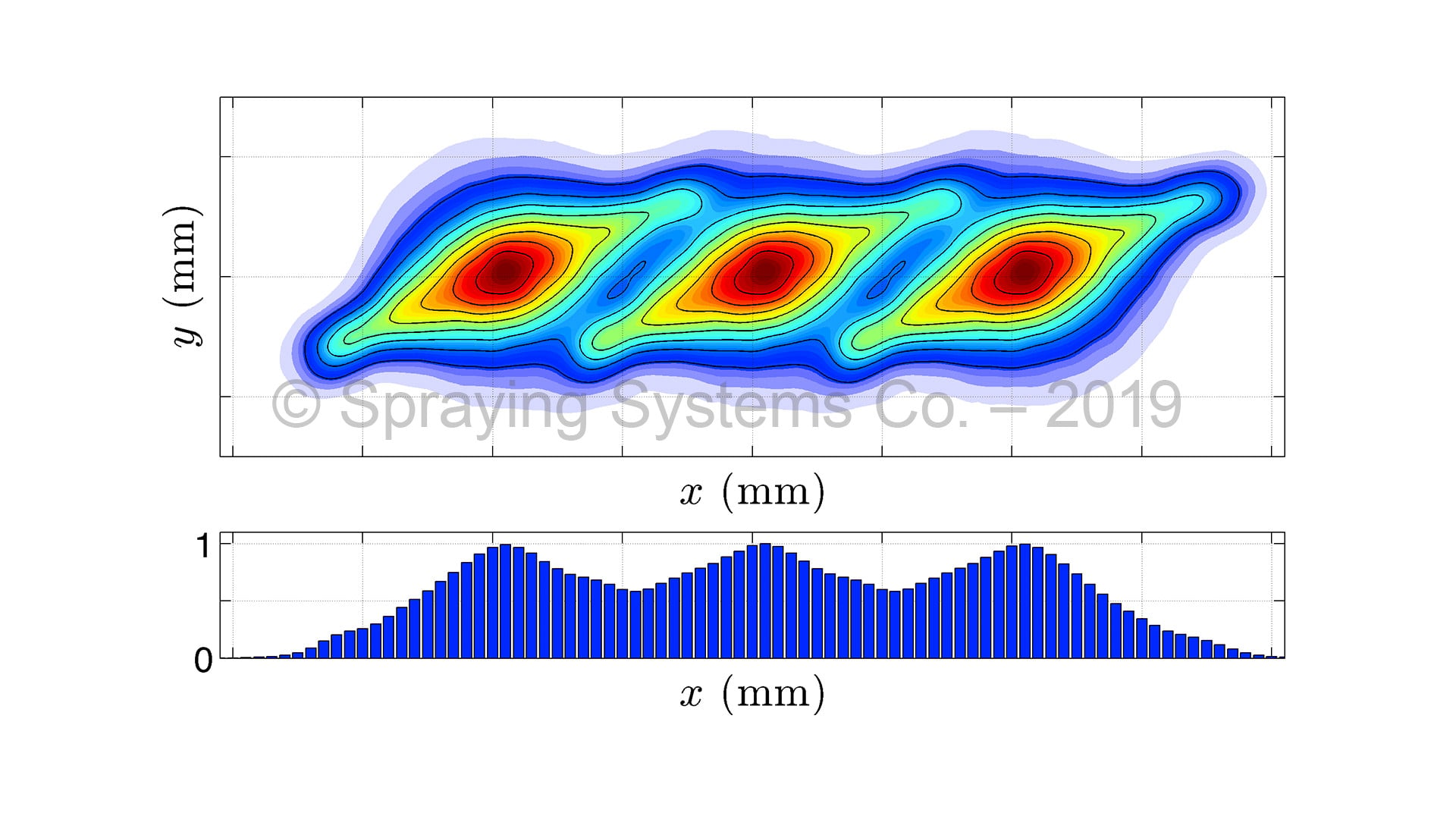

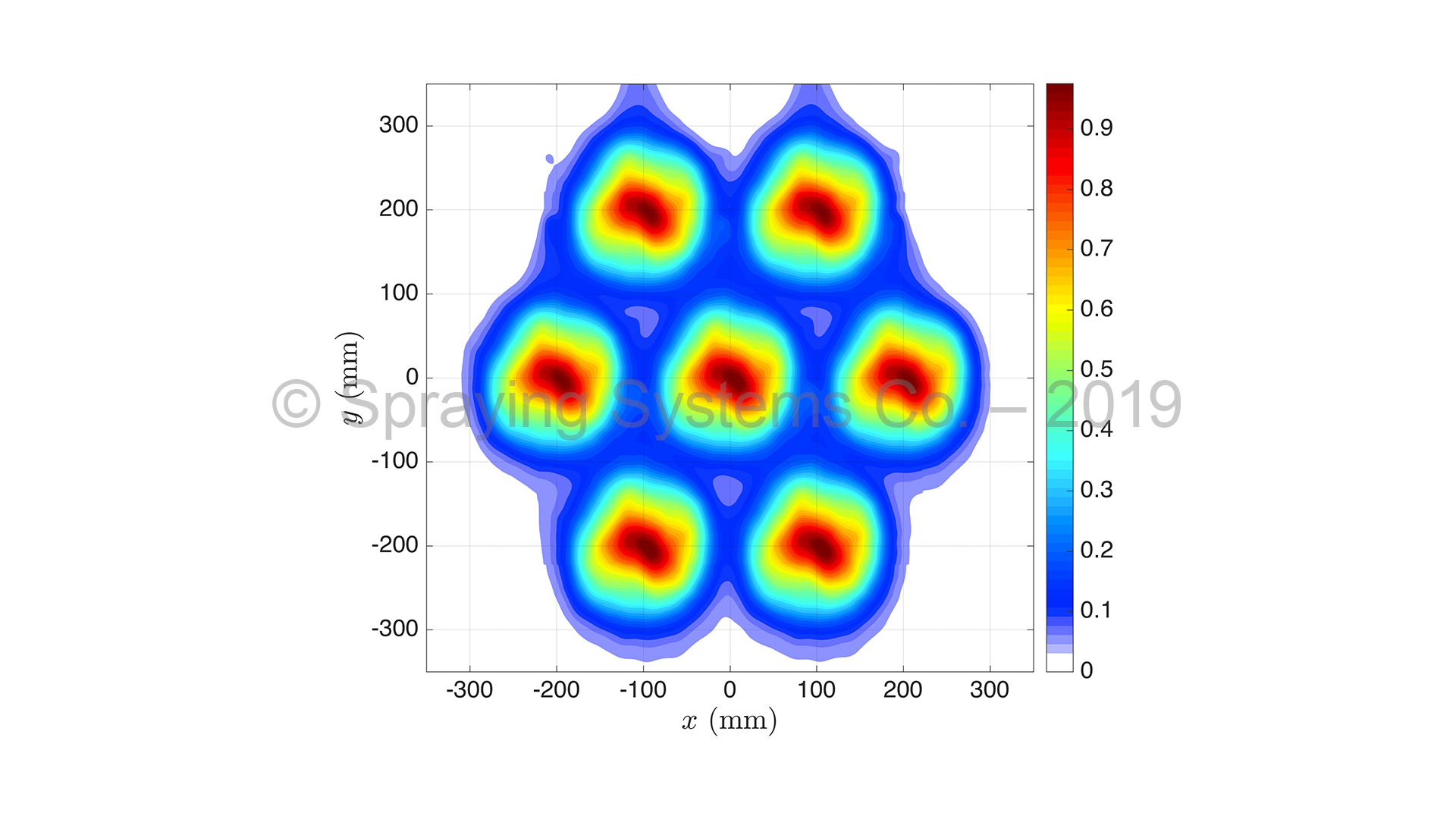

Typically, water is used as the spray medium during LSI measurements. The water droplets scatter the laser light according to the Mie theory, which results in illumination from each droplet equivalent to its surface area. The ensemble average result is a planar distribution representative of the total spray surface area. While this is similar to the volume distribution in many cases, it is often referenced as the spray concentration distribution and is instructive to assess local regions of high-vs.-low spray concentration.

-

Laser Induced Fluorescence (LIF) Method

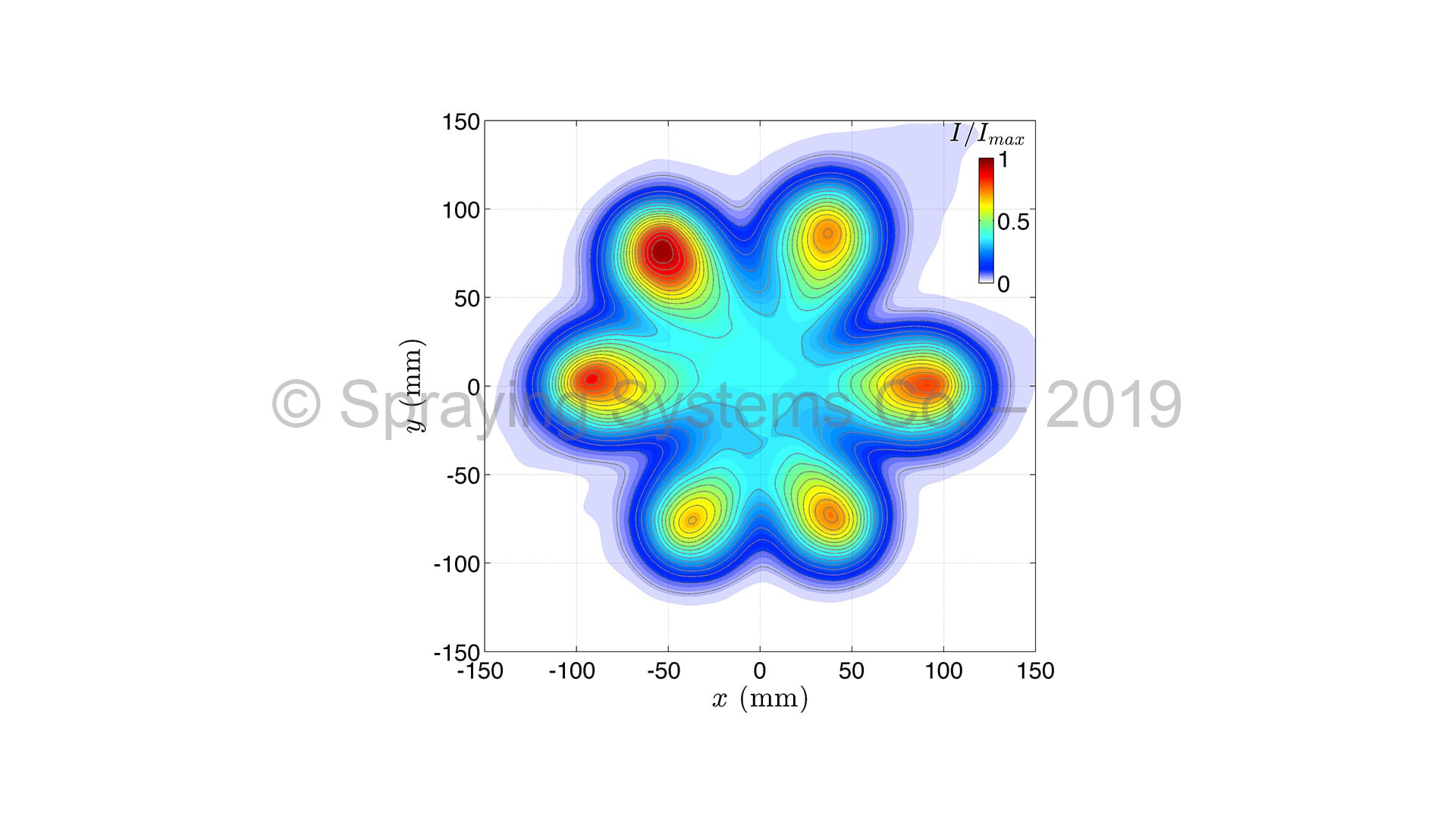

To obtain volume distribution measurements from the LSI instrument, it is necessary to treat the spray material with a doping agent. Laser induced fluorescence (LIF) measurements use a dye in the spray material, which, when subjected to the wavelength of light which is emitted by the LSI laser, causes the entire droplet to emit light. Thus, the LIF method results in planar spray distributions that are representative of the spray droplet volume.

In either Mie or LIF measurements, many instantaneous images are typically acquired and ensemble-averaged in order to arrive at an average planar spray distribution.