Carpet Manufacturer Improves Operations with AutoJet® Spray System

Carpet Manufacturer Improves Operations with AutoJet® Spray System

Manufacturer saves US$176,000 annually with the AutoJet carpet and flooring spray system

Problem:

A flooring manufacturer was using a foam rolling system to apply stain-resistant chemistries on commercial carpet. The chemicals, dispensed as foam, were rolled into the carpet. However, the foam was not applied uniformly to the carpet. Costly chemicals were wasted when the foam was over-applied. When the foam was under-applied, quality problems occurred after the carpet was installed. The foam rolling system also required fluoridated chemistry which limited the regions in which the carpet could be sold.

Solution:

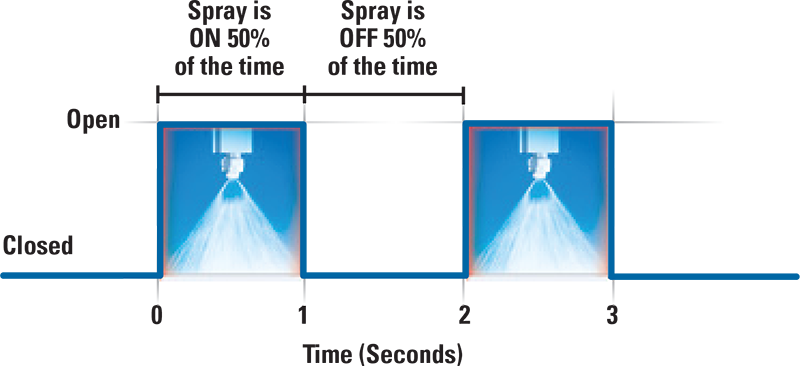

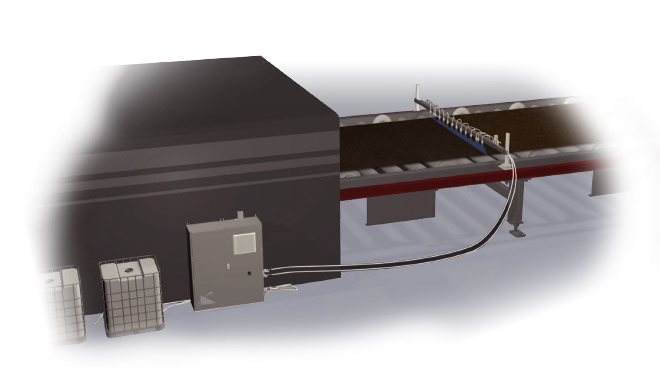

An AutoJet Carpet and Flooring Spray System is now used to apply the stain-resistant chemistries on the carpet. Hydraulic PulsaJet® electrically-actuated spray nozzles, mounted on a spray header, apply the exact volume of chemistry required uniformly across the width of the carpet just before it enters the dryer. The spray controller monitors operating conditions, makes automatic flow rate adjustments when line speed changes and turns nozzles on and off as needed when carpet width changes. Small day tanks, housed inside the control cabinet, enable fast change between chemistries and provide automatic mixing with water to the required concentration. Fluoridated chemistries can be used with the system but are not required.

Results:

The uniform coverage provided by the AutoJet Carpet and Flooring Spray System had a dramatic impact on operations. Applying the proper volume of chemistries reduced waste by more than 47,000 lbs (21,319 kg) per year – a savings of US$176,000. Carpet quality has improved and customer returns have decreased. In addition, now that non-fluoridated chemicals can be applied to the carpet, the manufacturer has expanded its distribution. The cost of the system was recouped in less than six months.

For complete details of this case study click here to see the PDF version.