The previous spray system used hydraulic nozzles on an oscillating arm. The system didn’t apply the release agent evenly across the width of the conveyor and lacked the ability to control flow based on the line speed. This resulted in sticking problems and a messy, unsafe production environment requiring frequent maintenance. When fouling of the system occurred, production was interrupted while the drying conveyor and surrounding area were cleaned by contract cleaners.

AutoJet release agent system

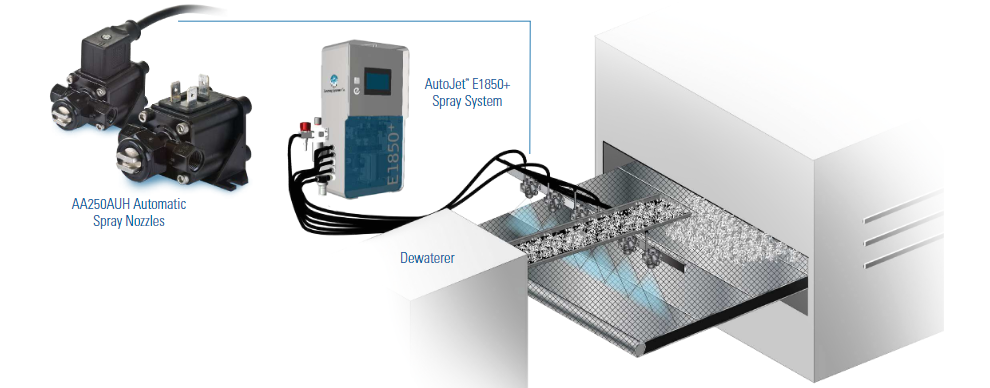

Spraying Systems Co.’s solution consisted of an AutoJet®E1850+ Spray System and a header equipped with six AA250AUH automatic spray nozzles. The spray header applies the release agent as a thin, uniform film across the entire width of the stainless steel conveyor. The AutoJet® system uses Precision Spray Control (PSC) to produce very low flow rates. As line speed changes, operators can easily adjust the flow rate of the nozzles without changing pressure. This is done whilst maintaining consistent spray coverage and drop size. Because the AA250AUH nozzles use only low pressure hydraulic atomization, mist and overspray are avoided.

Result

The AutoJet® release agent spray system provides a consistent application of release agent and has eliminated the previous mess and safety issues. The ESBR manufacturer has saved more than € 50,000 per year by reducing chemical use and cleaning expense. The payback on the new spray system was less than two months.