In Europe, 40% of all fresh water is consumed by industry. Alongside the food, chemical, primary metal and refined petroleum industries, the paper industry is one of the heaviest water consumers. In Slovenia and Sweden, the paper industry is even the largest withdrawer of industrial water.

In the last ten years, water costs have more than doubled in some areas, causing the paper industry to take a hard look at this expenditure. When wastewater disposal costs are included, it is even more significant.

Nozzle wear means water waste

Spray nozzles are at the heart of all the applications that utilize water throughout the mill. These seemingly simple components have a significant impact on performance and operating costs in moisturizing, cleaning, lubricating, edge trimming, bleaching, knock-off, gluing and dozens of other applications.

As spray nozzles wear, their orifices become larger and, at any given pressure, the flow rate will increase. Even slight nozzle wear that can’t be detected visually can be extremely wasteful, costing tens, sometimes hundreds, of thousands of dollars annually in increased operating expenses.

Worn nozzles that spray over capacity are wasting more than just water: Electricity costs will rise due to excess pump operation, and let us not overlook chemical consumption costs, these will also increase. The following illustrates just two examples of how quickly costs can rise.

Example 1. Dryer Section Shower Increased Operating Expenses

One shower with 70 nozzles spraying a release agent on dryer felt.

| New nozzles | 15% worn nozzles | |

| Water | € 5,335 | € 6,135 |

| Chemicals | € 46,800 | € 53,820 |

| Electricity | € 2,667 | € 3,118 |

| Total | € 54,802 | € 63,073 |

| Increased expense for one shower | € 8,271 |

Therefore, any facility with six showers in the dry end would face costs increasing by almost € 50,000 annually.

Example 2. Knock-off Shower Increased Operating Expenses

One shower with 72 nozzles in the dry end of a press section operating 15% over capacity due to worn nozzles.

| Additional water consumption annually | 124,570,640.9 liters |

| Increased annual cost of water an electricity for pump operation of one shower | € 65,156 |

In a facility operating ten showers, the money wasted each year soon exceeds half a million euro.

Ways to reduce water consumption:

1: Replace worn spray nozzles on a regular schedule

Worn spray nozzles are a common problem in pulp and papermaking, largely due to the chemicals and water being used. Many mills replace their spray nozzles annually. However, depending on the number and type of spray operations, the cost of replacement nozzles can be far less than the cost of wasted water – even if the nozzles are only 15 to 20% worn.

Spray Nozzle maintenance checklist

❏ FLOW RATE – EACH NOZZLE

Centrifugal Pumps: Monitor flow meter readings to detect increases, or collect and measure the spray from the nozzle for a given period of time at a specific pressure. Then compare these readings to the flow rates listed in the manufacturer’s catalogue or compare them to flow rate readings from new, unused nozzles.

Positive Displacement Pumps: Monitor the liquid line pressure for decreases; the flow rate will remain constant.

❏ SPRAY PRESSURE

In Nozzle Manifold Centrifugal Pumps: Monitor for increases in liquid volume sprayed. (Spraying pressure is likely to remain the same.)

Positive Displacement Pumps: Monitor pressure gauge for decreases in pressure and reduction in impact on sprayed surfaces. (Liquid volume sprayed likely to remain the same). Also, monitor for increases in pressure due to clogged nozzles. Visually inspect for changes in spray coverage.

❏ DROP SIZE

Examine application results for changes. Drop size increases cannot be visually detected in most applications. An increase in flow rate or a decrease in spraying pressure will impact drop size.

❏ IMPACT

Examine application results for premature wear of the fabric and/ or paper quality problems. This can indicate an increase in impact which cannot be detected visually.

❏ SPRAY PATTERN

Visually inspect each nozzle for changes in the uniformity of the pattern. Check spray angle with protractor. Measure the width of spray pattern on sprayed surface.

2: Change nozzle material to extend wear life and ensure optimal performance

Nozzles made from harder materials generally provide longer wear life. In addition to standard materials such as brass and stainless steel, more durable spray nozzles are often available in specialty materials, carbides or with ruby orifices.

Nozzles with a synthetic ruby orifice are frequently used for web trimming because they provide superior spray precision for a sharp, crisp edge and up to 2000 times greater wear resistance than brass. In addition, the stream remains steady even in the early stages of wear.

Many solid stream shower nozzles also are available with ruby or sapphire orifices. Keeping the stream integrity high for longer means better cleaning of the fabrics for a longer time period too.

Figure 2 provides standard abrasion resistance ratios for many of these materials to help you determine if you should consider a change.

| Spray Nozzle Material | Resistance Ratio |

| Aluminium | 1 |

| Brass | 1 |

| Polypropylene | 1 – 2 |

| Steel | 1.5 – 2 |

| Monel® | 2 – 3 |

| Stainless Steel | 4 – 6 |

| Hastelloy® | 4 – 6 |

| Hardened Stainless Steel | 10 – 15 |

| Stellite® | 10 – 15 |

| Silicon Carbide (nitride bonded) | 90 – 130 |

| Ceramics | 90 – 200 |

| Carbides | 180 – 250 |

| Synthetic ruby or sapphire | 600 – 2,000 |

3: Reduce spray pressure if performance

Although it is not always possible, decreasing pressure (which will slow the liquid velocity through the orifice) may help reduce the rate at which the orifice wears.

4: Use self-cleaning nozzles or strainers to protect nozzles and minimize wear

In many applications, orifice deterioration and clogging are caused by solid dirt particles in the sprayed liquid. This is particularly common in systems using continuous spray water recirculation. In an average production process, recycling of water enables approximately 17 uses before discharge, as opposed to one or two uses without recirculation.

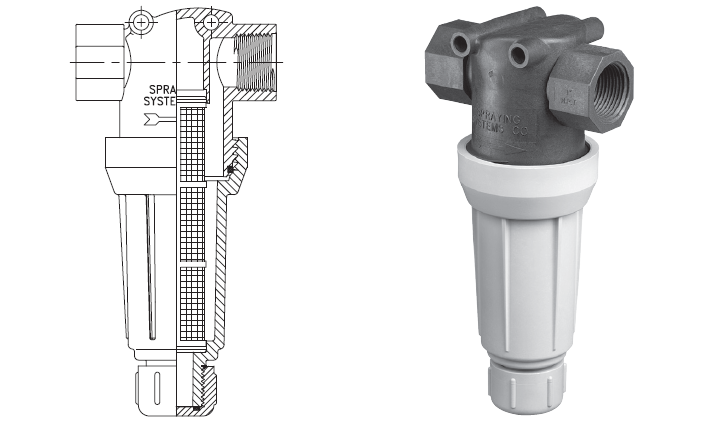

Self-cleaning nozzles feature a piston type design. When line pressure is low, the piston retracts to purge debris from the nozzle orifice. Self-cleaning nozzles are ideal for use in showers with high solids content in the water and also inside paper machines because of the compact design.

Strainers, or nozzles with built-in strainers, trap larger particles and prevent debris from entering the nozzle orifice or vane and thus significantly reduce wear.

5: Use spray guns instead of open hoses

For clean up throughout the mill, use low-pressure spray guns instead of open hoses. This can reduce water consumption by 50% or more. Also, ensuring water is “on” only when it is actually needed will significantly reduce waste.

6: Automate your chest and/or tank cleaning

Tanks and chests are often cleaned manually by workers equipped with hoses or by filling and draining the tank or chest multiple times. Depending on the chest size, these cleaning methods can use hundreds of liters of water every time the chest is cleaned.

Automated tank cleaning systems are an effective alternative to manual cleaning. Some mills have reported saving up to € 50,000 per year per stock chest, simply by switching to automated cleaning.

Clean-in-place (CIP) systems use spray nozzles to provide controlled, thorough cleaning and rinsing. High-impact, fluid driven or motorized tank washers and automated turnkey systems are other options. In addition to using considerably less water than manual and fill/drain methods, automated tank cleaning offers many other benefits like:

- Faster, more thorough cleaning

- Reduced use of costly chemicals

- Reduced disposal costs

- Improved worker safety

- Reduced labour costs and maintenance downtime.

Turnkey systems integrate pumps, sensors, motors and valves designed to optimize the performance of tank cleaning nozzles. Systems can be equipped to recirculate cleaning liquid in a closed loop, allowing the reuse of a portion, or all, water and chemical cleaning solutions.

Optimized spray systems contribute to a sustainable and profitable future

Spray nozzles are precision components designed to yield specific performance under specific conditions. Just because a nozzle is spraying doesn’t mean that it is working optimally.

When showers and/or moisturizing, coating, cleaning and web trimming operations are not optimized, a valuable, natural resource is being depleted; furthermore, many other costly problems may be encountered such as:

- Quality control issues

- Unscheduled production downtime

- Increased maintenance

- Increased consumption of costly chemicals and electricity

To ensure your system is operating at peak efficiency and not wasting water, begin with an audit of your spray system. An audit is typically offered at no cost and may require several hours of work.

Most experts agree that, in order to ensure the world has enough safe water in the future, action must be taken – and aggressively so! For the sake of future generations, it is imperative that the practice of water conservation is not viewed as some unimportant distraction. If you’d like to learn more about how you can reduce water consumption in your mill be sure to contact us directly.