Optimizing Spray Technology for

Power Generation

Optimizing Spray Technology for

Power Generation

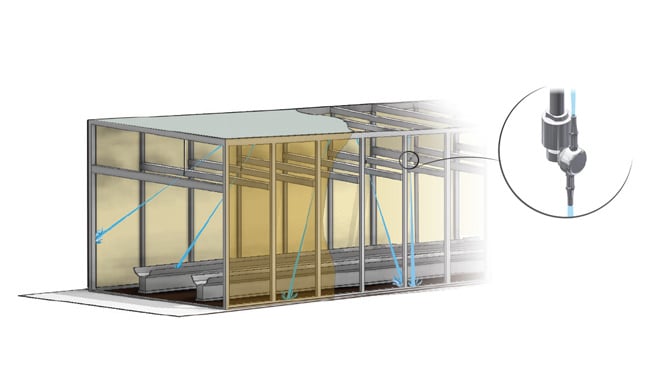

Power plants and OEMs around the world rely on us for NOx control as well as gas cooling and conditioning solutions. The experts at Spraying Systems Co. can work with you to model your spray operations and provide new insight into areas that could be improved. We can help you select the right nozzles, optimize injector placement within a vessel, or design and fabricate a custom system that complies with PED 2014/68/EU and ASME codes and delivers the performance you need, complete with testing and documentation.