Engineered Wood Manufacturing

Engineered Wood Manufacturing

In the engineered wood industry, your spray operations directly impact production efficiency and product quality. We’ve developed a wide range of spray nozzles and PanelSpray® automated systems to optimize the process for manufacturers of OSB, MDF, plywood, particleboard and other wood products.

Common Applications

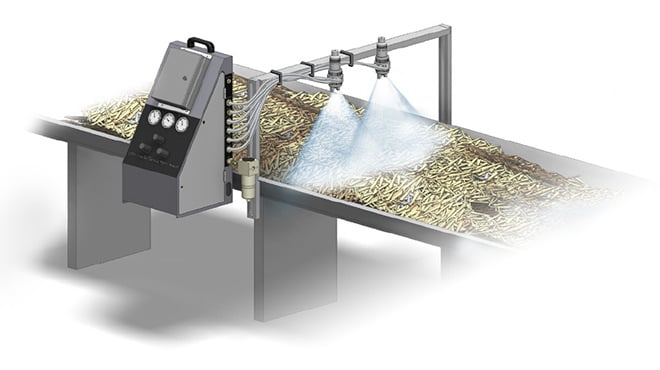

Moisture Application

Applying moisture to the surface of the mat before entering the press is essential. Our PanelSpray-MS system for moisture application delivers — spraying water uniformly with minimal overspray, and adjusting to accommodate changes in line speed.

Product Spotlight

PanelSpray®-MS system increases production and improves quality for OSB manufacturer.

Wax Application

Maintaining wax temperature to ensure consistent application on panels can be difficult. That’s why we’ve developed technology specifically for wax application.

Product Spotlight

PanelSpray-WX system keeps wax properly heated, prevents clogging and automatically adjusts flow rate based on wood throughput.

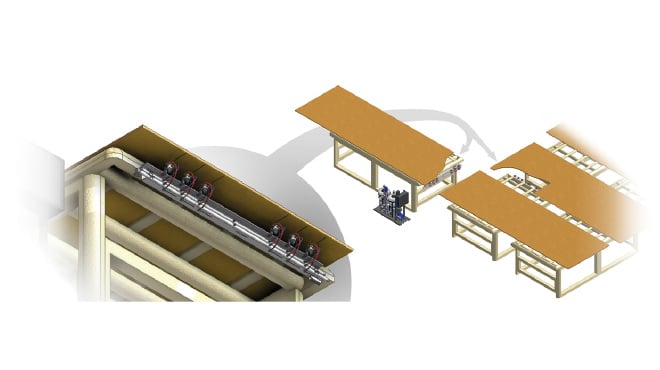

Marking

The PanelSpray-NM system is easily integrated with existing plant equipment. Nozzles are arranged in headers to produce any nail line pattern required by your customers. Single or double pass marking patterns are possible.

Product Spotlight