Cement Manufacturing

Cement Manufacturing

In harsh cement manufacturing environments, the right nozzles, spray lances and high-pressure spray guns can make all the difference on the bottom line. That’s why cement plants depend on spray technology and expertise from Spraying Systems Co. We’ve worked with cement plants of all sizes all over the world, helping them improve cement quality and productivity while reaching sustainability goals.

Common Applications

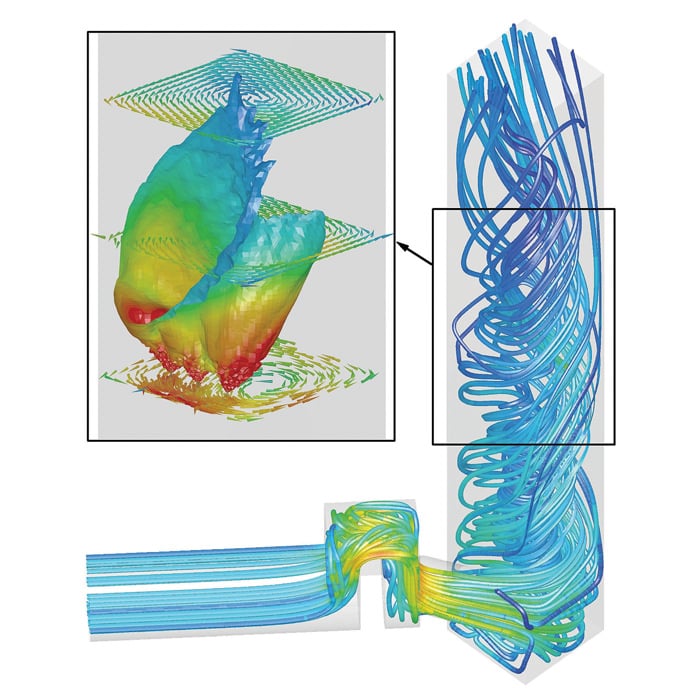

Gas Cooling

Proper temperature control throughout your cement manufacturing process ensures efficiency as well as quality. Use our spray technology to meet your specific temperature requirements in the gas conditioning tower, clinker cooler and more.

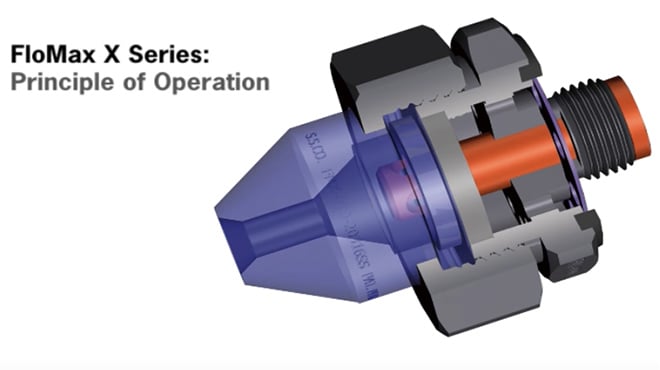

Product Spotlight

FloMax® air atomizing nozzles produce small drops using less air than competitive nozzles, allowing for lower operating costs.

Dust Suppression and Control

Our experts understand how to install the best solutions for dust suppression as well as dust control.

Product Spotlight

Both WhirlJet® andFullJet® hydraulic nozzles can be used for effective, efficient dust control.

High-pressure Cleaning

Cement manufacturing leaves deposits in rotary kilns and clinker coolers that impact process efficiency. Our spray technology is specifically designed to keep every surface clean and safe.

Product Spotlight