applications

Strip Cooling

Our wide range of nozzles and headers properly cool strips to achieve metallurgical requirements.

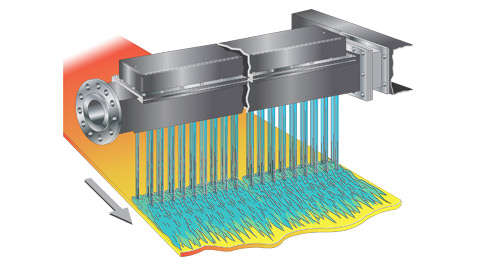

Laminar Flow Headers

Our laminar flow headers provide consistent and cost-effective sheet cooling on runout tables. Operating at pressures as low as 0.9 psi (0.06 bar), laminar cooling uses water very effectively.

- The rod-like column of water from solid stream VeeJet® nozzles is superior to U-tube nozzle cooling.

- Header does not need to be filled or drained to interrupt the flow pattern, enabling simplified header sequencing and reduced lag time.

- An internal baffle plate ensures precise flow distribution and simplifies maintenance and replacement.

- Slit-style laminar flow headers that produce an evenly distributed curtain-like sheet of water help reduce cracking and other defects.

Flat Spray Headers

Custom-designed headers equipped with flat spray nozzles are ideal for cooling hot strip and plate products. They are suitable for use with runout tables, strip wash and lubrication. Headers can be designed to allow use of nozzles with different spray angles.

- A wide range of nozzle sizes, capacities, spray angles and materials are available.

- Compact profile allows close positioning to target to maximize heat removal and extend roll life.

- Overlapping patterns provide efficient, uniform cooling.