Pet Food Manufacturer Saves US$8,000 per Month Using Longer-Lasting SprayDry® Nozzles

Pet Food Manufacturer Saves US$8,000 per Month Using Longer-Lasting SprayDry® Nozzles

Problem:

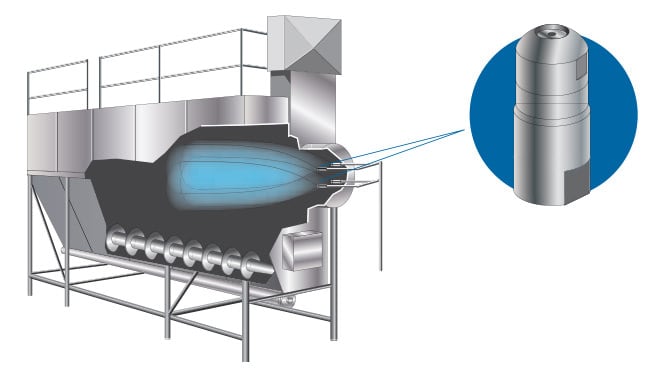

A pet food manufacturer wanted to find a more economical solution for spray drying meat proteins without compromising quality. The manufacturer operates three box dryers 24 hours per day and downtime for cleaning the dryers and replacing worn nozzles is limited. Tungsten carbide nozzles were used in the dryers, spraying at 3,000 psi (207 bar). Wear life of the nozzles components was short – orifice disks required replacement every 4 days and swirl units every 12 days. The frequent replacement and ongoing maintenance increased downtime and operating costs.

Solution:

Spraying Systems Co.’s SKH-MFP SprayDry nozzles with a slotted core design provided the ideal solution to the manufacturer’s problem. SKH-MFP nozzles are constructed of a special tungsten carbide material that offers increased abrasion resistance and extends wear life. In addition, the SKH-MFP nozzles produce the required spray angle and droplet size spraying at 2,500 psi (172 bar). Operating at a lower pressure minimizes wear on the pump and nozzles, further extending service life.

Other benefits of the SKH-MFP include large free passages that reduce the potential for plugging, a hand-tightened nozzle cap for faster and easier maintenance and direct retrofit into existing piping.

Results:

The new SprayDry® nozzles have maintained ingredient quality and reduced maintenance time. In addition, the SKH-MFP nozzles are almost 60% less expensive and provide significantly longer wear life than the previously used nozzles. Combined, these factors have reduced the manufacturer’s operating costs by more than US$8,000 per month.

For complete details of this case study click here to see the PDF version.