Detecting Nozzle Wear

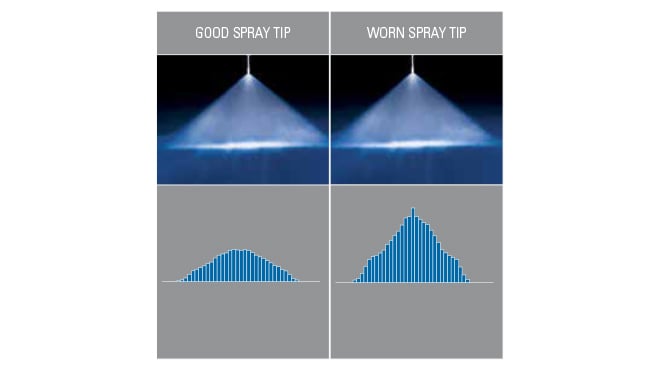

Nozzle wear is difficult to detect because it usually isn’t visible. You can’t notice gradual erosion of nozzle orifices just by examining the nozzle or spray pattern. You need to watch the nozzle closely for other evidence of nozzle wear. Watch this video to compare the performance of a new and worn nozzle.

Indicators of Nozzle Wear

As nozzle orifices wear, you might see these differences in your spray operations:

- Change in Flow Rate

In all nozzles, flow rate increases as the surfaces of the orifice or internal vane / core begin to deteriorate. In applications using positive displacement pumps, which provide the same capacity regardless of pressure, spraying pressure decreases as the nozzle orifice enlarges, resulting in lower spray velocities and spray impact. - Increase in Drop Size

As nozzle orifices wear, the liquid flow increases or the spraying pressure drops, resulting in larger drop sizes and less total liquid surface area. - Deterioration of Spray Pattern Quality

Nozzle wear affects the spray pattern in different ways, depending on the nozzle type. For hollow cone nozzles, the spray pattern becomes less uniform and develops streaks. For full cone spray nozzles, the spray pattern distribution deteriorates as more liquid flows at the center of the pattern. For flat fan sprays, the spray pattern develops streaks and heavier flows in the center, accompanied by a decrease in the effective spray angle coverage. - Lowered Spray Impact

Spray impact is lowered as worn nozzles operate at lower pressures. However, in applications with centrifugal-type pumps, impact may actually increase because of the increased flow through the nozzle.

Spray Nozzle Maintenance

The best way to minimize wear on your nozzles and optimize their performance is to properly maintain them. Document your system performance immediately after installing nozzles in order to establish a baseline for later comparisons. Then, on a regular basis, check these aspects of your system:

- Flow rate of each nozzle

- Spray pressure in nozzle manifold

- Drop size

- Spray pattern

- Nozzle alignment

- Application results